Aerated concrete hybrid packaging system

A technology of aerated concrete and chain conveyor, applied in the directions of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of low efficiency, exhausting workers' physical energy, poor stacking aesthetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

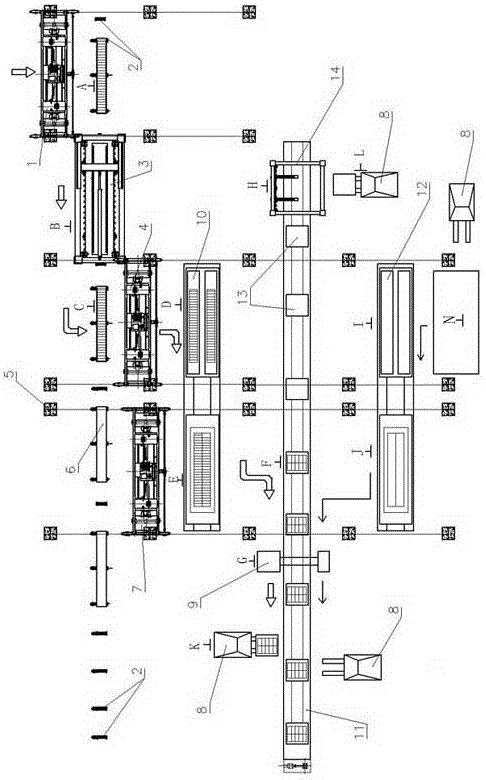

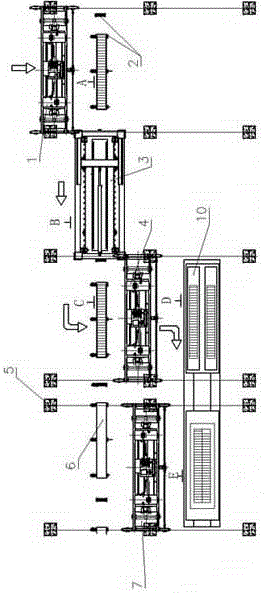

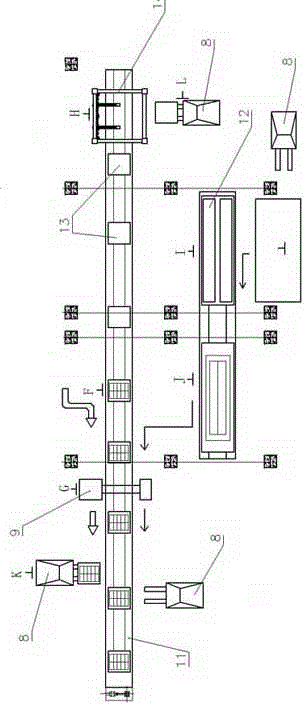

[0017] The accompanying drawings show the technical solution of the present invention and its implementation examples, and the implementation details and working principle will be further described below in conjunction with the accompanying drawings.

[0018] The present invention provides a mixed packing system for aerated concrete. The system is arranged in a rectangular shape as a whole and includes a chain conveyor 11 located in the middle. A threaded packing machine 9 is arranged in the middle of the chain conveyor. Templates are respectively arranged on both sides of the chain conveyor. The billet station and the block billet combining station, the vertical chain conveyor is equipped with a row crane, which is located above the billet blending station, and transfers the workpieces after billet blending to the chain conveyor.

[0019] The blocks are connected to the block splitting machine 3 through the roller table 2, and the split blocks are transported through the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com