Bracing system and construction method for construction of differential underground structure

A technology of underground structure and construction method, which is applied in the direction of basic structure engineering, excavation, construction, etc., to achieve the effect of improving material utilization, reducing the input of enclosure structure materials, and avoiding construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

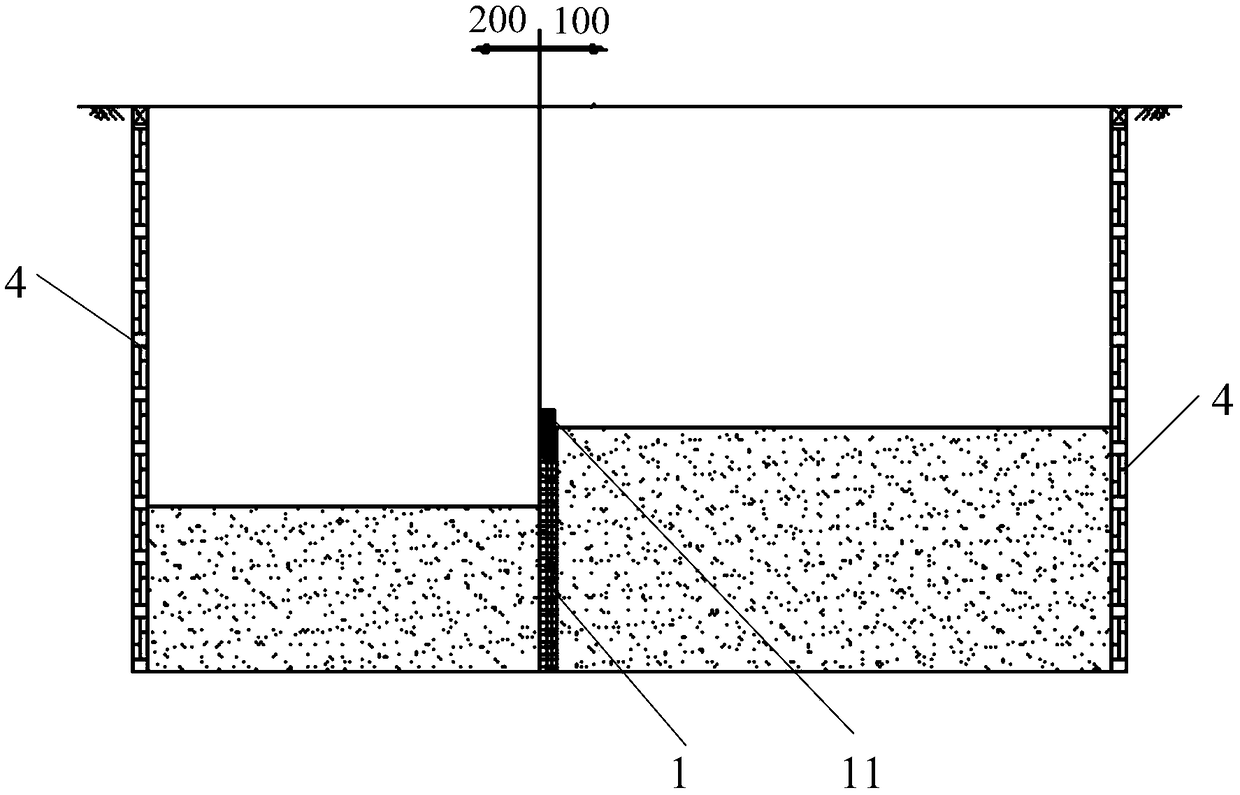

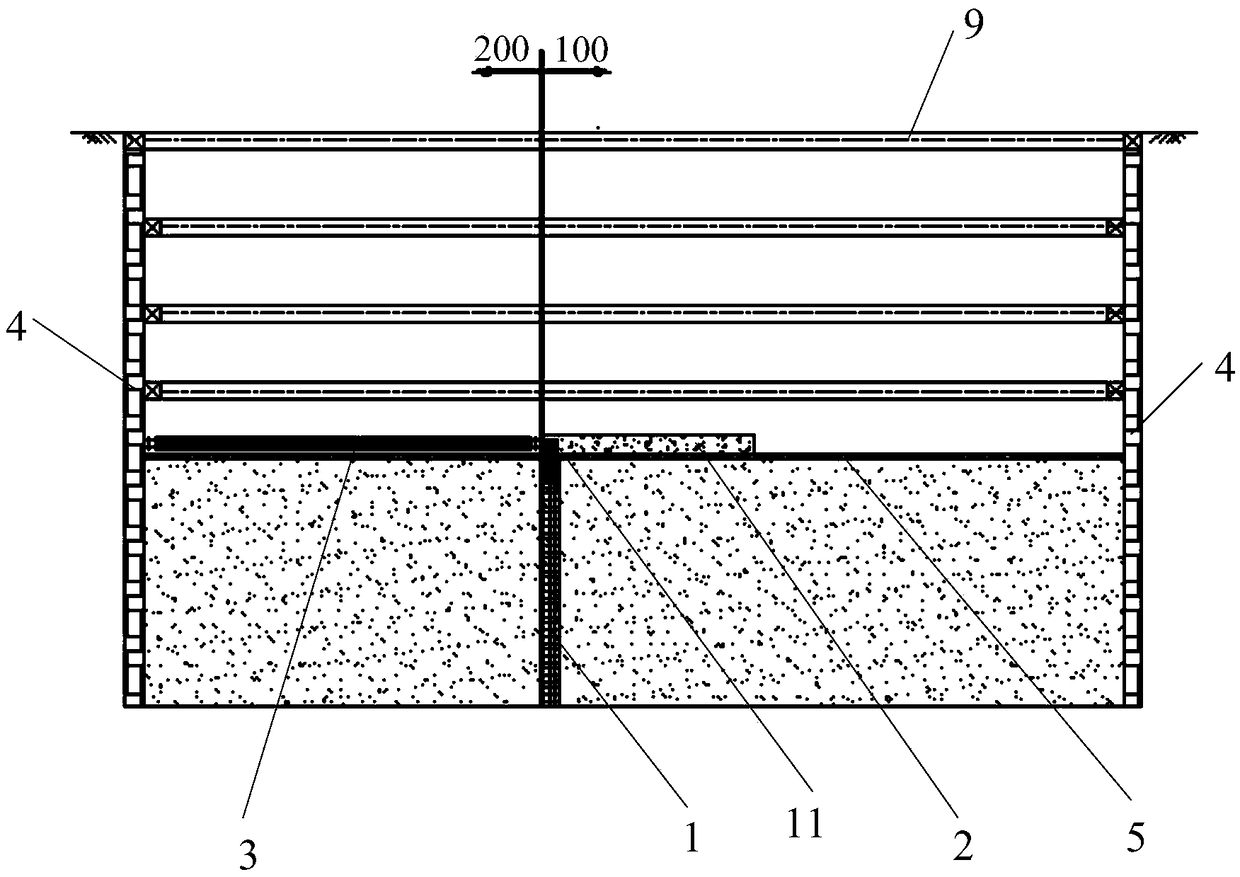

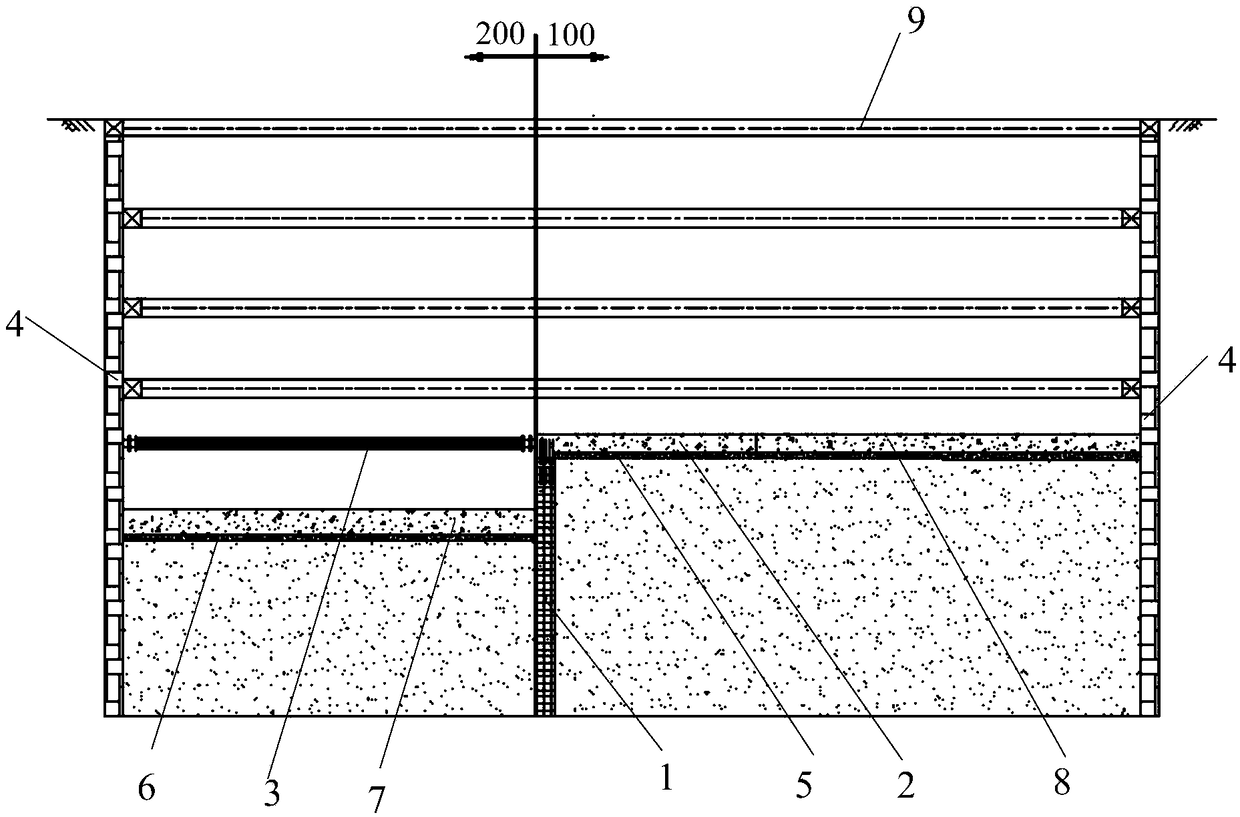

[0035] Such as Figure 1-5 As shown, the present invention provides a brace replacement system for differential underground structure construction, which includes a brace replacement wall 1 located at the junction of the deep and shallow areas 100, a brace replacement wall 1 located at the side of the shallow region 100 close to the brace replacement wall 1 The bottom plate of the cast structure 2 and the supporting beam 3 located above the deep area 200, the top of the supporting wall 1 is connected to the bottom plate of the cast structure first, and one end of the supporting beam 1 is connected to the outside of the deep area 200 The other end of the retaining wall 4 is connected to the top of the supporting wall 1 or the structural bottom plate 2 . Specifically, before the excavation of the foundation pit, it is firstly divided according to the number of floors of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com