Blade special for axial-flow fan

A technology of axial flow fans and blades, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of failure to improve fan efficiency, inconvenient use, loud noise, etc., and improve efficiency and improve efficiency , Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

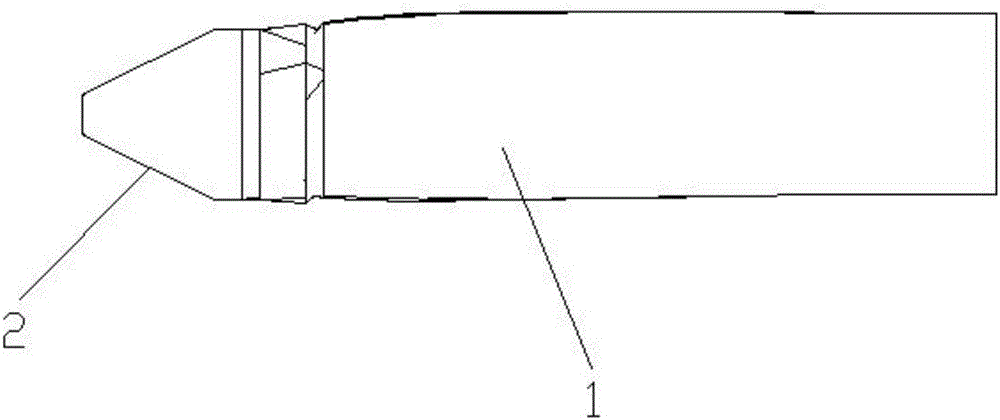

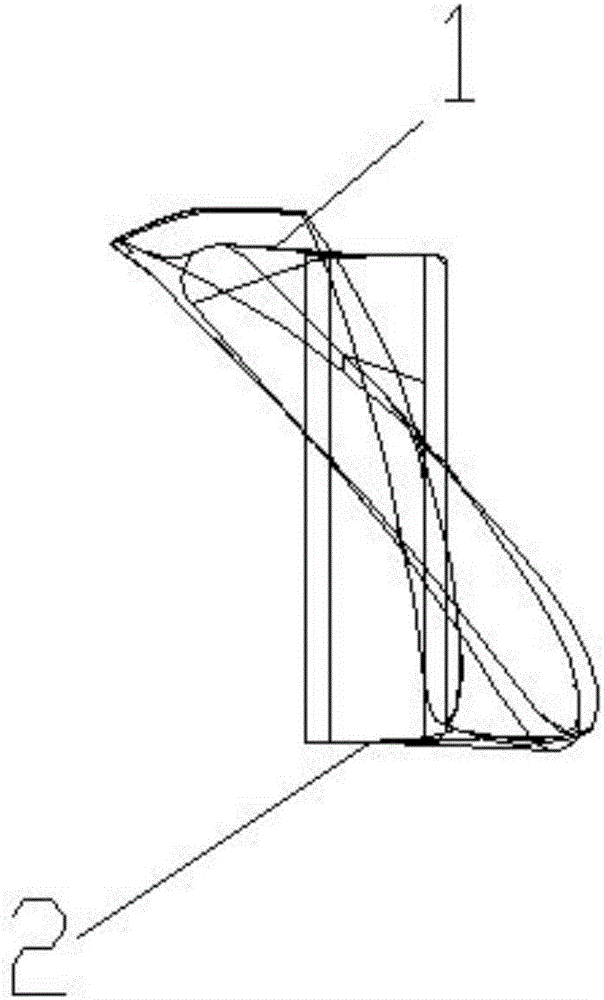

[0029] Refer to attached Figure 1-3 As shown, a special blade for an axial flow fan provided by the present invention includes a blade surface 1 and a petiole 2. The blade surface 1 is composed of a number of arc curved surfaces in sequence, and each arc curved surface has a corresponding chord length. The chord lengths of several circular arc surfaces decrease successively, and the circular arc surface with the longest chord length is connected with the petiole.

[0030] Wherein, the arc surface is specifically an airfoil section.

[0031] In the above-mentioned blade surface 1, the overall radian curve of the blade surface 1 is first long and then short and then long. To a certain extent, and then longer. A plurality of arc-curved surfaces form a relatively twisted blade surface 1 .

[0032] Wherein the petiole 2 is a trapezoidal structure.

[0033] In the above embodiment, due to the isolated airfoil method as the basis, the entire blade surface maintains a relatively ...

Embodiment 2

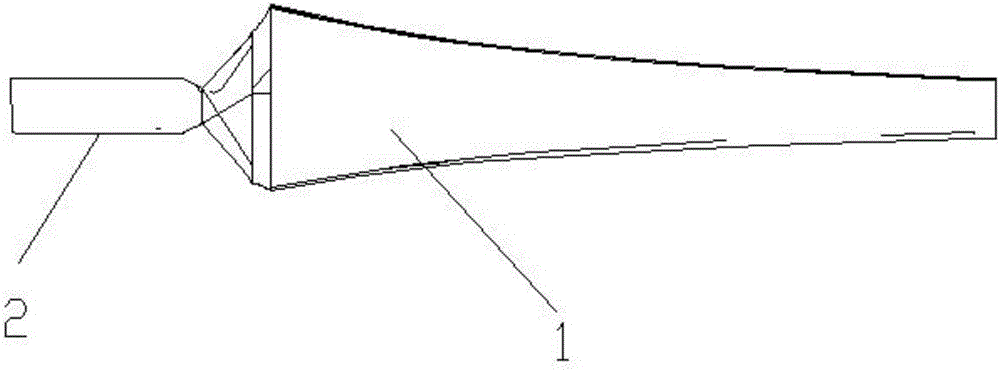

[0035] Refer to attached Figure 4-6 As shown, a special blade for an axial flow fan includes a blade surface 1 and a petiole 2. The blade surface 1 is composed of seven arc-shaped surfaces sequentially, including a first arc-shaped surface 101 and a second arc-shaped surface 102. , the third arc surface 103, the fourth arc surface 104, the fifth arc surface 105, the sixth arc surface 106 and the seventh arc surface 107, each arc surface has a corresponding chord length, and several arcs The chord lengths of the curved surfaces decrease successively, and the arc surface with the longest chord length is connected to the petiole 2 .

[0036] Wherein the petiole 2 is a cylindrical structure.

[0037] The arc surface is specifically an airfoil section.

[0038] During use, the chord lengths of the seven-segment arc surfaces decrease successively, and the ratio of the chord lengths of the seven-segment arc surfaces is: 206:190:180:170:166:162:160.

[0039] Wherein, the blade sur...

Embodiment 3

[0046] When the present invention is used in practice, different chord lengths and the like need to be designed according to the specifications of different models. The following table shows the blade specifications of 14 different models. The specific table 1 is the chord length data, and the table 2 is the maximum thickness (mm) and installation angle of the section airfoil, specifically:

[0047] Table 1

[0048]

[0049] Table 2

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com