Sensors for Metal Corrosion Monitoring

A metal corrosion and corrosion monitoring technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problem of inability to accurately monitor the corrosion degree of steel components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

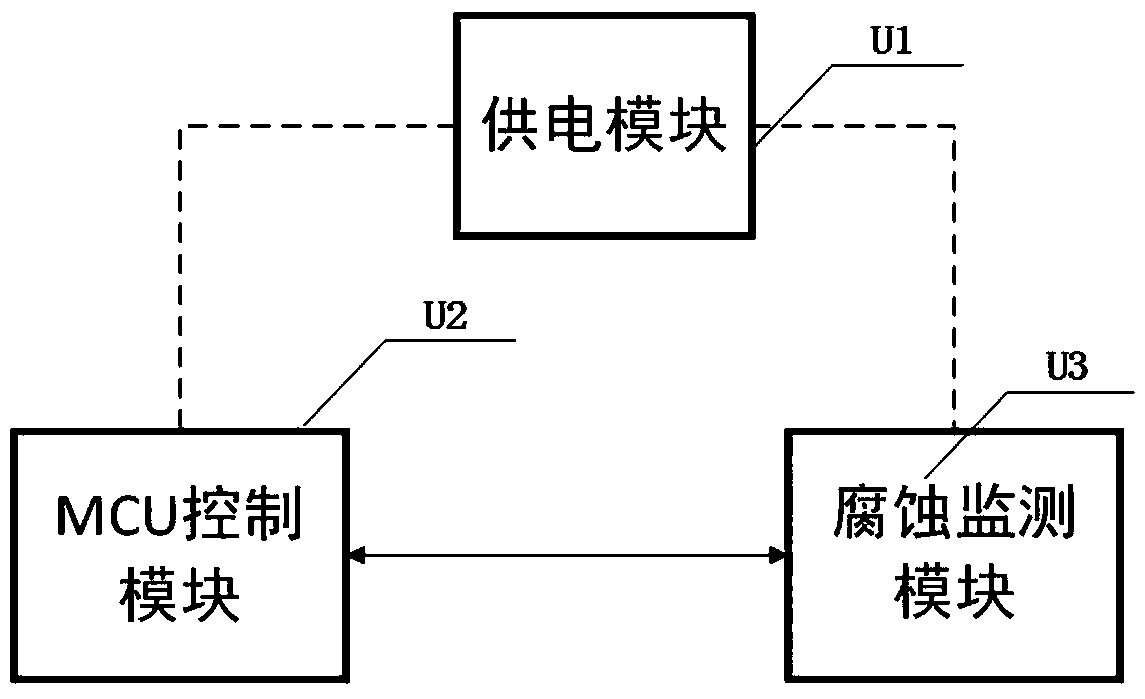

[0035] refer to figure 1 The sensor for metal corrosion monitoring of the present invention includes a power supply module U1, an MCU control module U2 and a corrosion monitoring module U3; the power supply module U1 is used to supply power to the MCU control module U2 and the corrosion monitoring module U3; the MCU control module U2 is used for Control the corrosion monitoring module U3, and analyze and process the information from the corrosion monitoring module U3; the corrosion monitoring module U3 is used to monitor the corrosion status of the metal to be tested, and upload the data to the MCU control module U2 in real time.

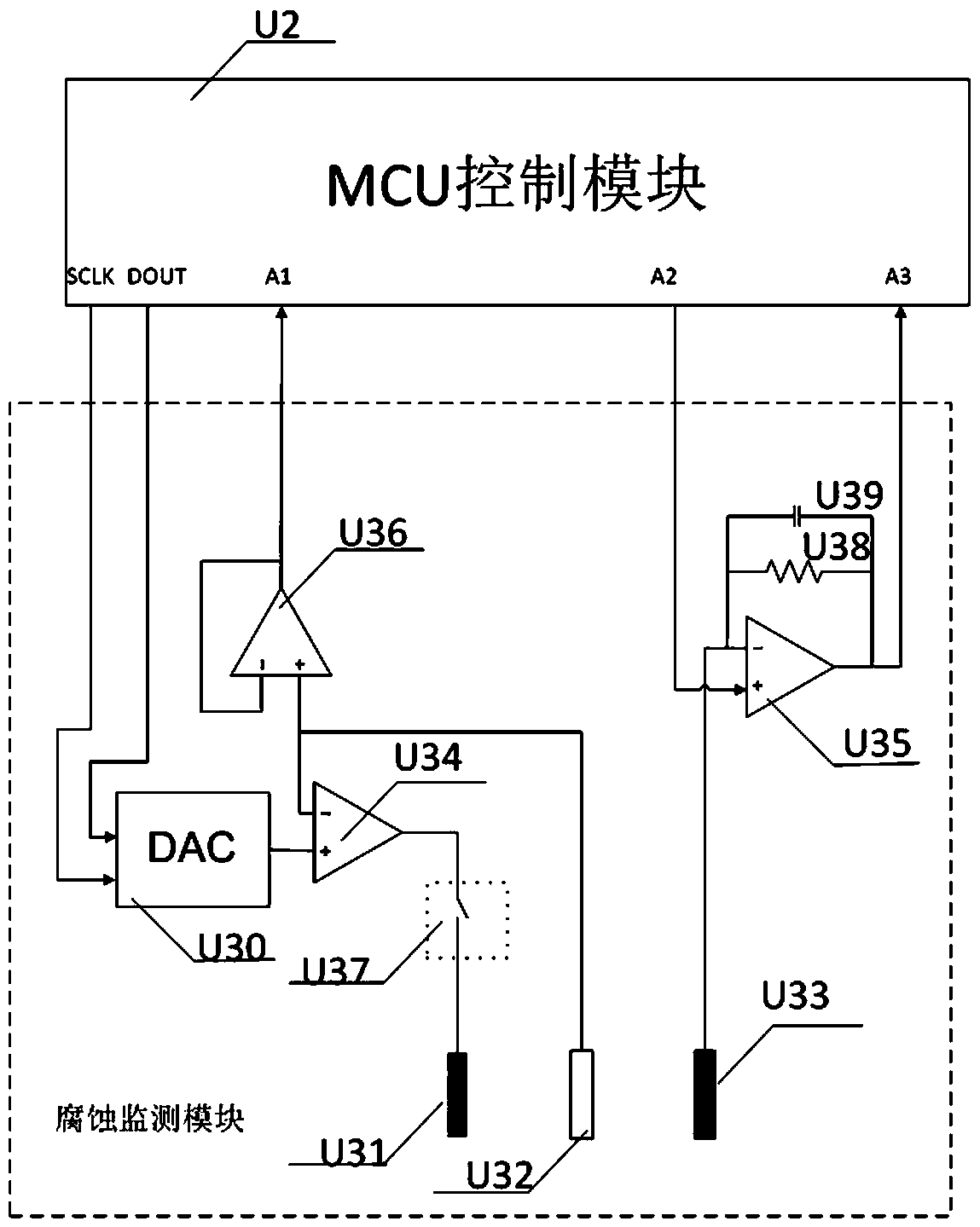

[0036] refer to figure 2 , the corrosion monitoring module includes DAC module U30, counter electrode U31, reference electrode U32, working electrode U33, No. 1 operational amplifier U34, No. 2 operational amplifier U35, low offset zero-dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com