Machine vision-based agricultural product volume rapid measurement device and measurement method

A technology of machine vision and measuring devices, applied in measuring devices, optical devices, instruments, etc., to achieve strong real-time performance and ensure rotation invariance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

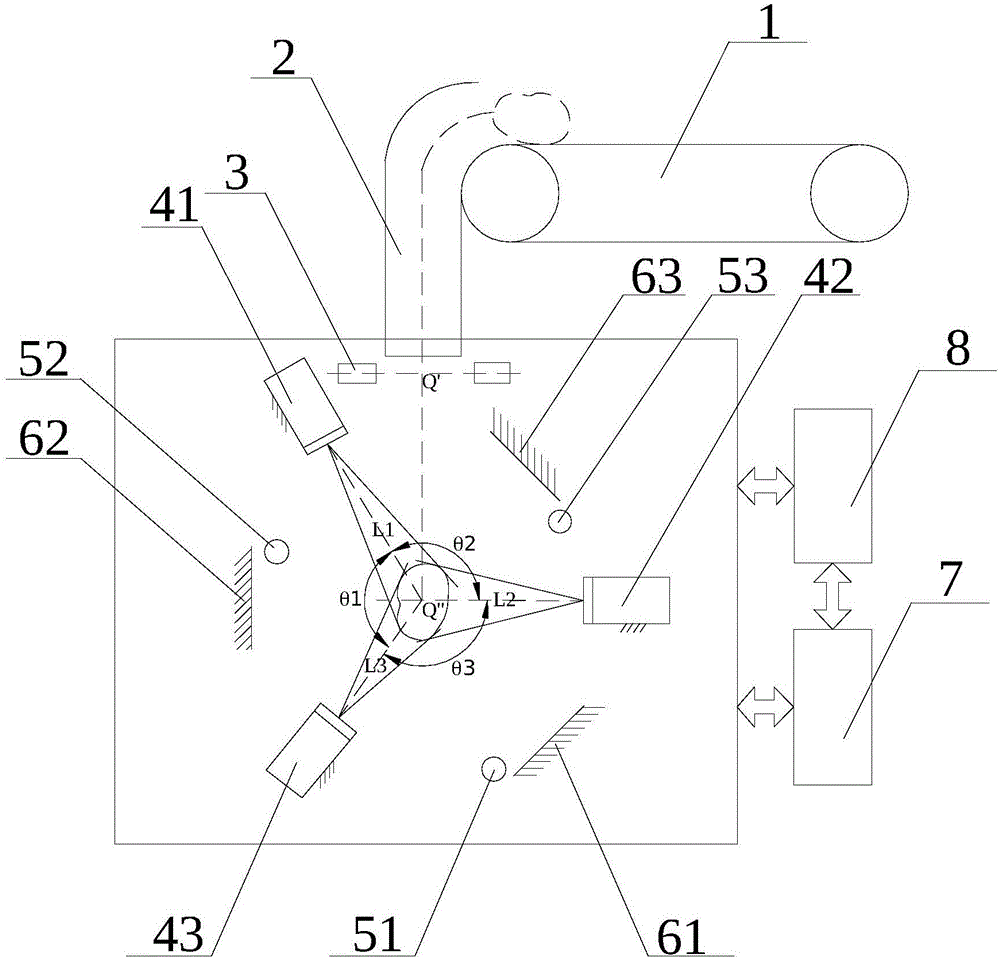

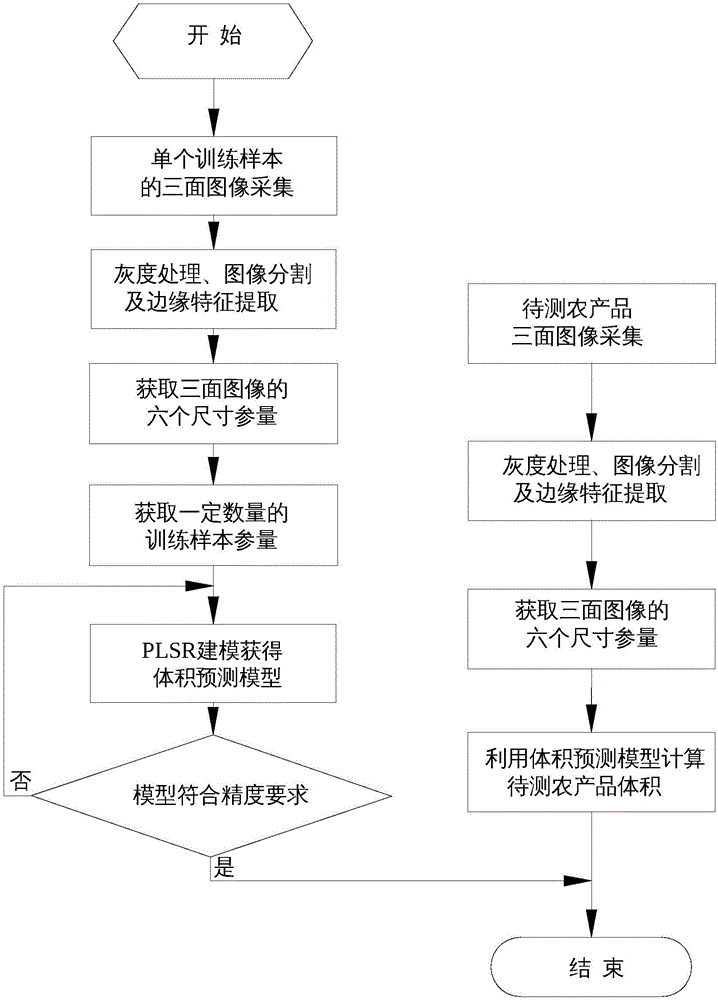

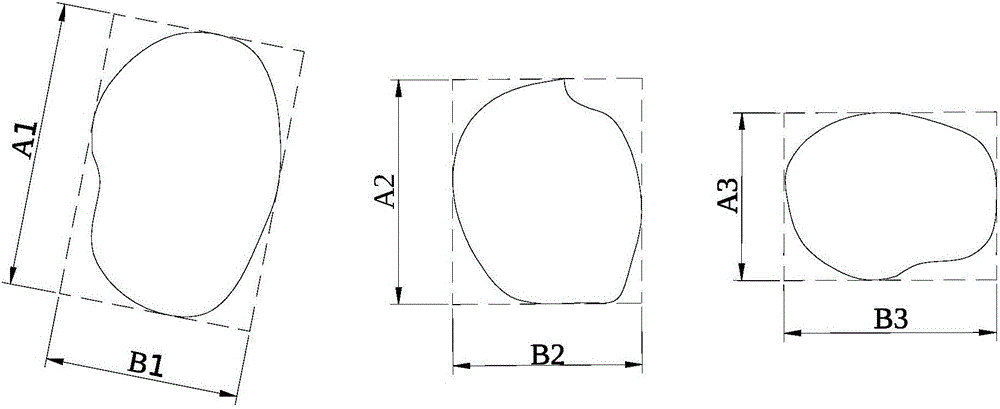

[0022] A rapid measurement device for agricultural product volume based on machine vision, such as figure 1 As shown, the camera lens of the three CCD industrial cameras 41, 42, 43, including the transmission device, the switch-type detection sensor 3, and the angled high-speed color CCD industrial cameras 41, 42, 43, all adopt zoom lenses. The camera driver 8 is driven by an FPGA-core drive board to implement camera driving and related algorithms (such as image filtering, image segmentation and other preprocessing, volume prediction algorithms, etc.), and the image acquisition processor 7 is a processing board with a DSP device as the core Realization, the camera driver 8 and the image a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com