A Thin Film Transistor with High Effective Power

A thin film transistor and semiconductor technology, applied in transistors, semiconductor devices, electrical components, etc., can solve problems such as large power consumption, and achieve the effects of reducing power consumption, increasing area, and improving effective power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

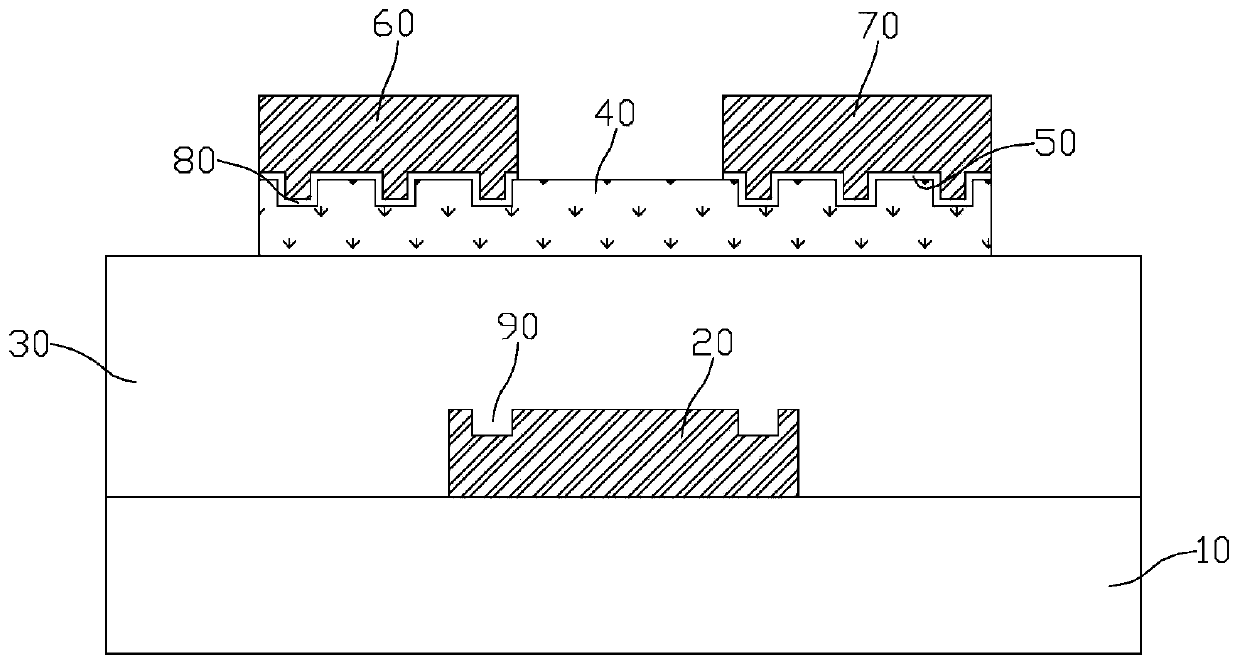

[0028] See figure 1 As shown, a thin film transistor with high effective power includes: a substrate 10, a gate 20 disposed on the substrate 10, a gate insulating layer 30 disposed on the substrate 10 and covering the gate 20, and a gate insulating layer 30 on the surface of the gate insulating layer 30. The semiconductor layer 40, and the source level 60 and the drain level 70 arranged on the semiconductor layer 40, and the source electrode 60 is arranged opposite to the drain electrode 70, and the upper surface of the semiconductor layer 40 forms several first The groove 80, the ohmic contact layer 50 is formed on the projection of the source electrode 60 and the drain electrode 70 on the upper surface of the semiconductor layer 40, the shape of the ohmic contact layer 50 changes with the shape of the upper surface of the semiconductor layer 40, and the source electrode 60 and the drain electrode 70 are formed On the ohmic contact layer 50, when the first groove 80 forms a p...

Embodiment 2

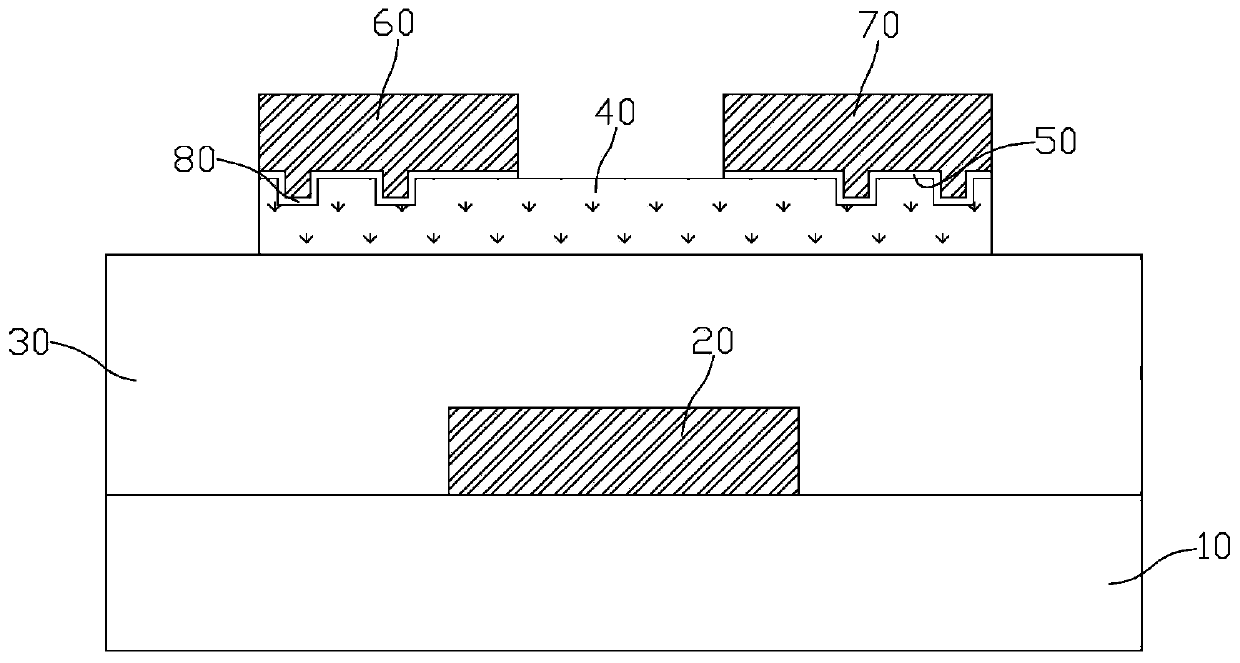

[0033] See figure 2 As shown, in this embodiment, four first grooves 80 are formed on the upper surface of the semiconductor layer 40, two of which are formed at the projection of the source 60, and two are formed at the projection of the source and drain 70. The first groove 80 does not form a projection at the gate 20, and there is no need to form a second groove 90 on the upper surface of the gate 20, which can simplify the manufacturing process, and the rest of the structural configuration is the same as that of Embodiment 1.

Embodiment 3

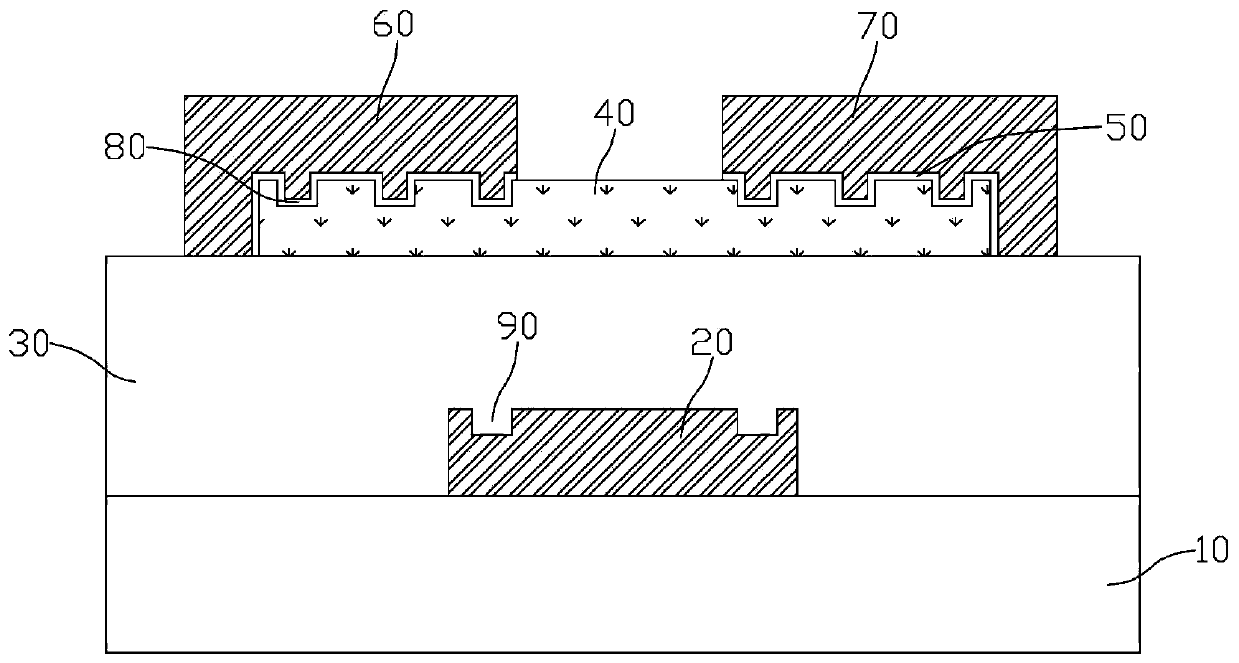

[0035] See image 3 As shown, in this embodiment, the ohmic contact layer 50 is also formed on both sides of the semiconductor layer 40, and the source electrode 20 and the drain electrode 70 extend on both sides of the ohmic contact layer 50, wrapping the two sides of the ohmic contact layer 50, further increasing the metal The semiconductor contact area reduces power consumption, and the rest of the structural configuration is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com