Tree shaper

A shaper and tree technology, applied in the fields of botanical equipment and methods, gardening, gardening tools/equipment, etc., can solve the problems of dangerous operation, high applicable environment limitations, and high use cost of aerial work vehicles, and achieve stable work. , avoid accidental damage, improve the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

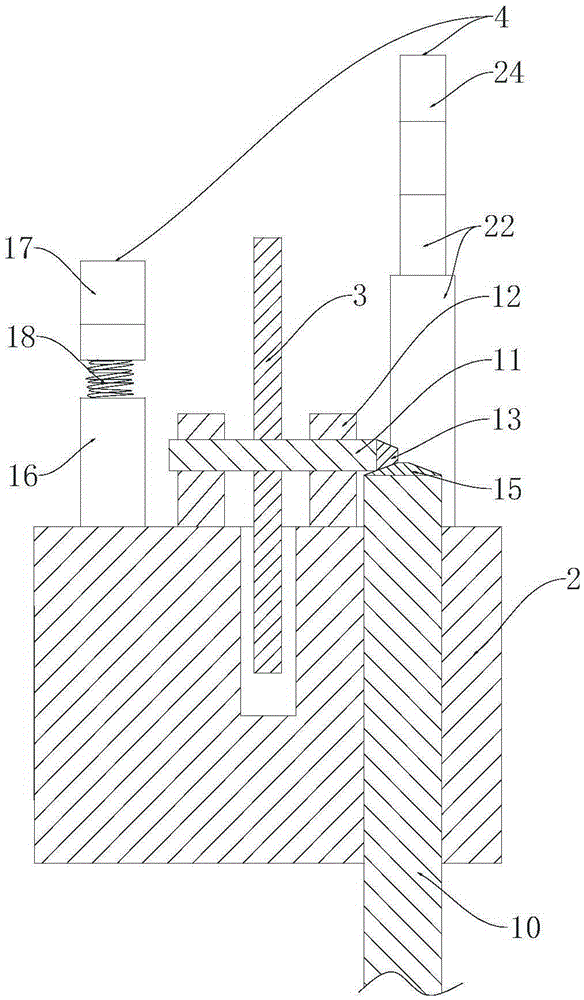

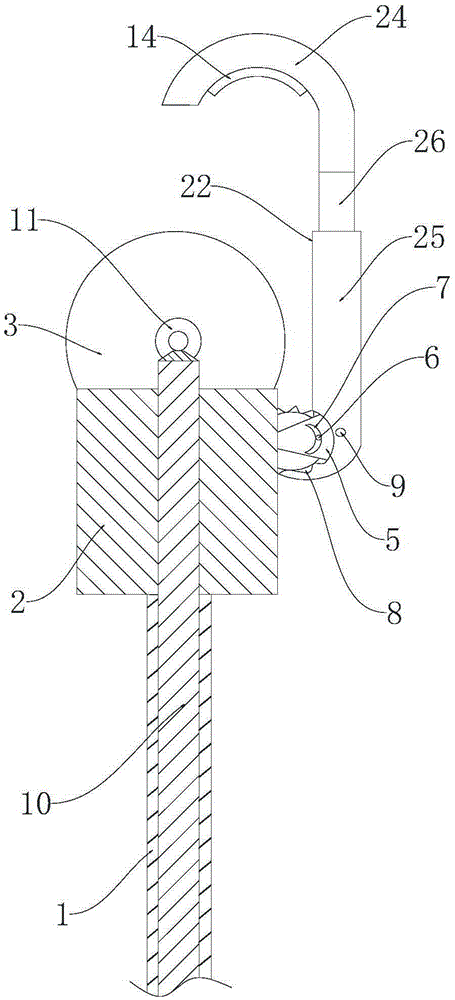

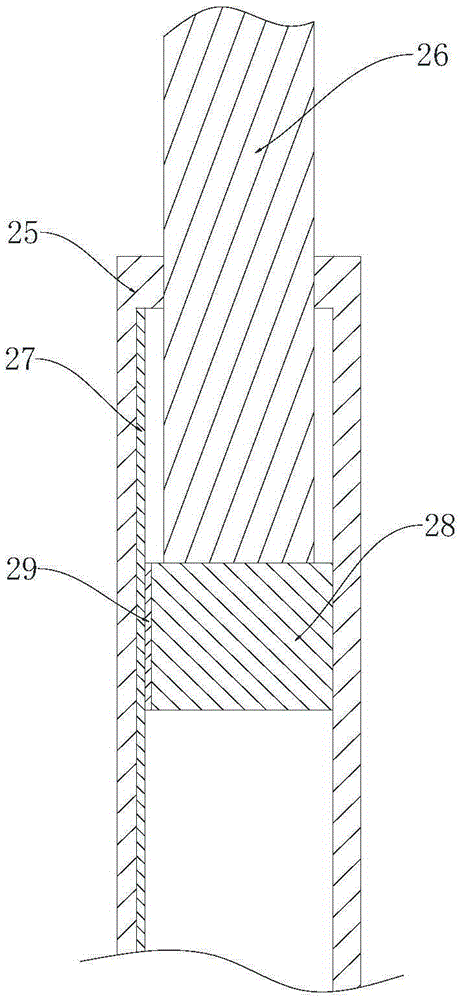

[0028] Such as Figure 1 to Figure 6 As shown, a tree shaper includes a screw rod 10, a cutting base 2 and a cutting assembly. The cutting assembly includes two support blocks 12 that are arranged oppositely and are fixedly connected to the upper end surface of the cutting base 2 and are rotatably arranged on the two support blocks 12 through bearings. The rotating shaft 11 on the rotating shaft 11 is covered with a gear saw blade 3, the lower end of the screw rod 10 is covered with a sleeve 1, the upper end of the screw rod 10 runs through the cutting base 2, and a Bevel gear 13, one end of rotating shaft 11 is equipped with bevel gear 15 that matches with bevel gear 13; Hanging arm bar 22, short hanging arm bar 16 and long hanging arm bar 22 are all installed on the cutting base 2 side walls, and both are respectively positioned at the both sides of gear saw blade 3, and the upper end of short hanging arm bar 16 is connected by spring 18 There is a first hanging arm head 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com