Preparation method and application of cdse quantum dot/bi12tio20 composite photocatalyst

A technology of quantum dots and composite light, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of green environmental protection processing technology, high-efficiency processing technology, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

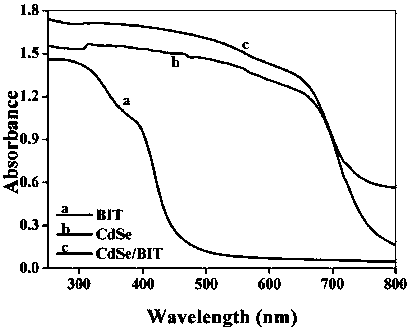

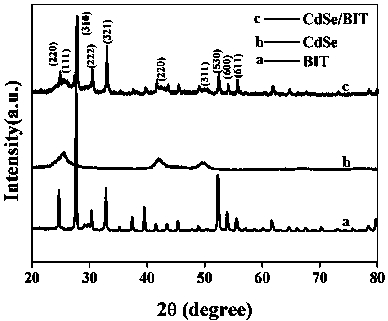

Image

Examples

Embodiment 1

[0029] (1) Bi 12 TiO 20 Preparation of photocatalyst:

[0030]Weigh 2.06g of bismuth nitrate and 0.12mL of tetrabutyl titanate into a small beaker, add deionized water to make it fully dissolved, magnetic stirring assists the reaction, adjust KOH to pH=14, and ultrasonically make it more dispersed uniform. Pour it into a high-pressure reactor and heat it in an oven, take it out and cool it naturally, centrifuge the solution, wash it with deionized water for 3 times, put it into a drying oven to dry, and obtain Bi 12 TiO 20 catalyst of light.

[0031] (2) Preparation of NaHSe precursor solution:

[0032] Weigh 0.0011mol of Se powder and 0.015mol of NaBH 4 Put it into a glass reaction bottle, add deionized water, magnetic stirring assists the reaction, and pass N through the whole reaction. 2 Protect until a white precipitate appears in the reaction, draw the supernatant liquid, which is the NaHSe precursor.

[0033] (3) CdSe quantum dots / Bi 12 TiO 20 Preparation of co...

Embodiment 2

[0037] (1) Bi 12 TiO 20 Preparation of photocatalyst:

[0038] Weigh 2.06g of bismuth nitrate and 0.12mL of tetrabutyl titanate into a small beaker, add deionized water to make it fully dissolved, magnetic stirring assists the reaction, adjust KOH to pH = 14, and ultrasonically make it more dispersed uniform. Pour it into a high-pressure reactor and heat it in an oven, take it out and cool it naturally, centrifuge the solution, wash it with deionized water for 3 times, put it into a drying oven to dry, and obtain Bi 12 TiO 20 catalyst of light.

[0039] (2) Preparation of NaHSe precursor solution:

[0040] Weigh 0.0011mol of Se powder and 0.015mol of NaBH 4 Put it into a glass reaction bottle, add deionized water, magnetic stirring assists the reaction, and pass N through the whole reaction. 2 Protect until a white precipitate appears in the reaction, draw the supernatant liquid, which is the NaHSe precursor.

[0041] (3) CdSe quantum dots / Bi 12 TiO 20 Preparation of...

Embodiment 3

[0045] (1) Bi 12 TiO 20 Preparation of photocatalyst:

[0046] Weigh 2.06g of bismuth nitrate and 0.12mL of tetrabutyl titanate into a small beaker, add deionized water to make it fully dissolved, magnetic stirring assists the reaction, adjust KOH to pH = 14, and ultrasonically make it more dispersed uniform. Pour it into a high-pressure reactor and heat it in an oven, take it out and cool it naturally, centrifuge the solution, wash it with deionized water for 3 times, put it into a drying oven to dry, and obtain Bi 12 TiO 20 catalyst of light.

[0047] (2) Preparation of NaHSe precursor solution:

[0048] Weigh 0.0011mol of Se powder and 0.015mol of NaBH 4 Put it into a glass reaction bottle, add deionized water, magnetic stirring assists the reaction, and pass N through the whole reaction. 2 Protect until a white precipitate appears in the reaction, draw the supernatant liquid, which is the NaHSe precursor.

[0049] (3) CdSe quantum dots / Bi 12 TiO 20 Preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com