A sealant coating device suitable for the back door of the trunk

A coating device and sealant technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problem of poor rust-proof performance of the trunk back door seal, poor consistency of sealant thickness, and the need to apply the sealant in sections. Covering and other problems to achieve the effect of improving the anti-rust performance of sealing, ensuring continuity and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

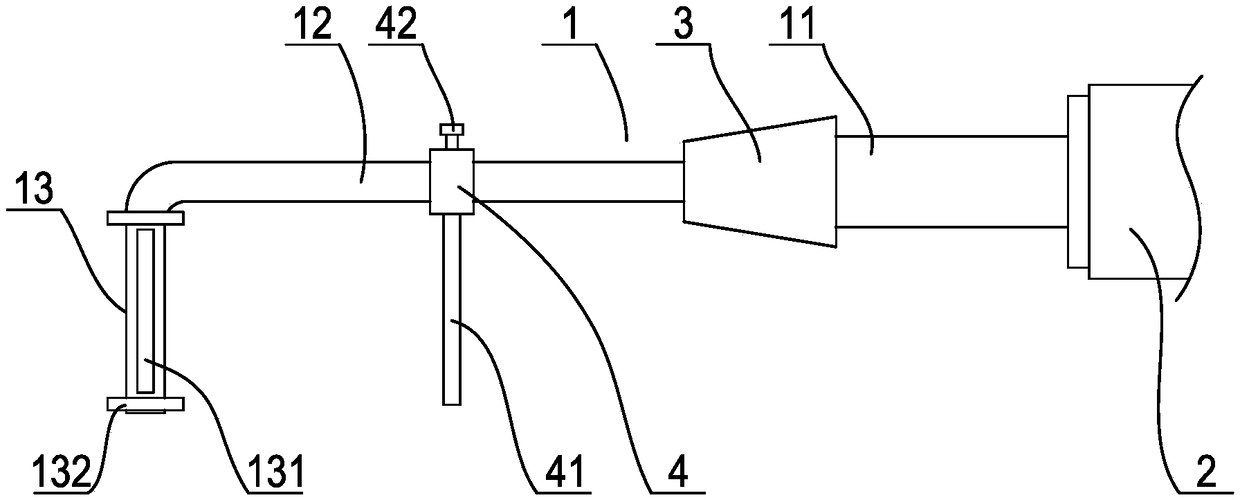

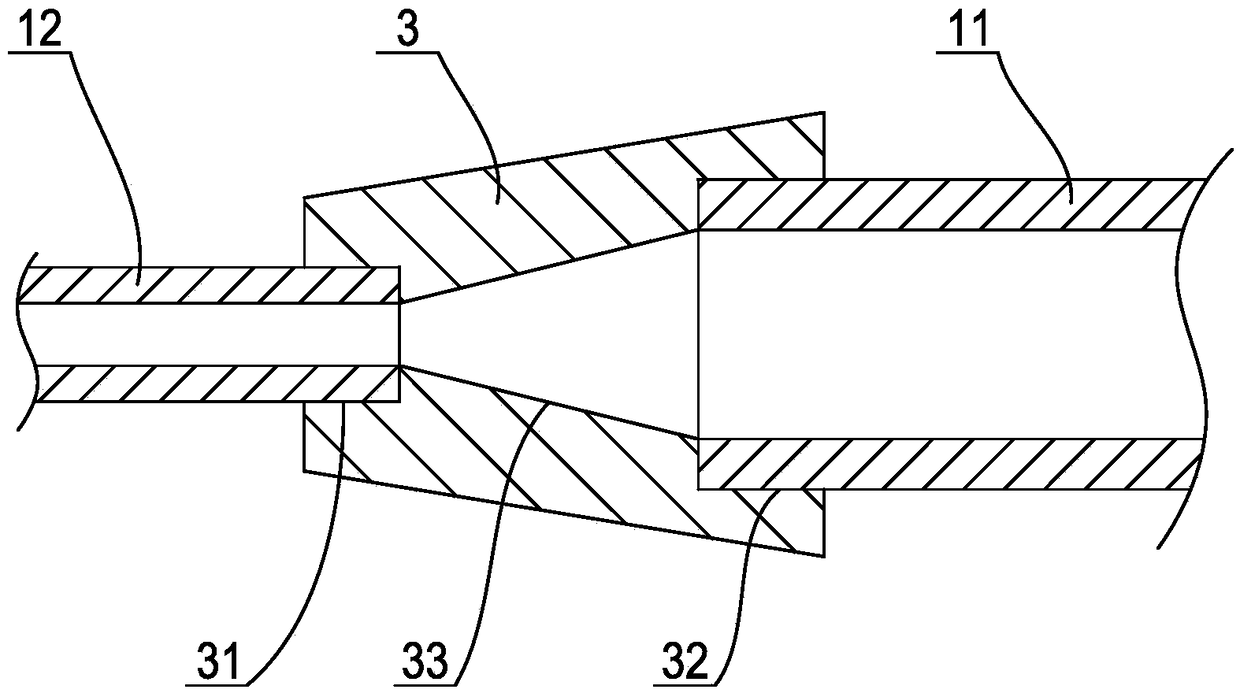

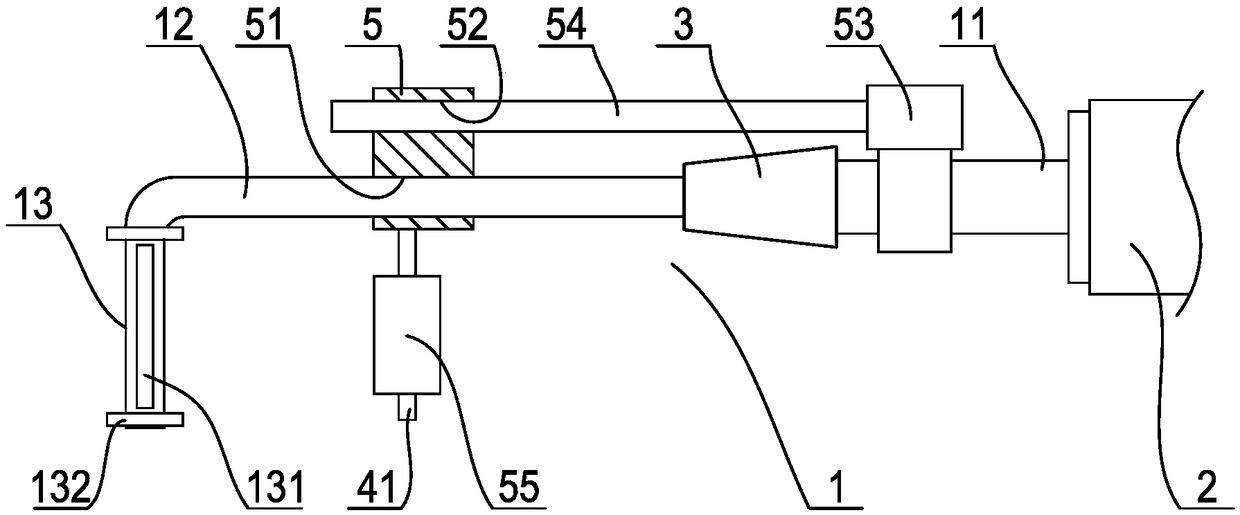

[0027] Embodiment 1: as figure 1 As shown, a sealant coating device suitable for the back door of the trunk includes a rubber outlet pipe 1 connected by a connecting section 11 at the rear end and an inserting section 12 at the front end. The cross-sectional area of the inserting section 12 is smaller than that of the connecting section 11 cross-sectional area. The rear end of the connecting section 11 is detachably connected to the sealant conveying device 2, so as to facilitate the conveying of the sealant, and facilitate disassembly and maintenance. Specifically, the connection section 11 and the sealant delivery device 2 can be connected through a delivery hose equipped with a quick joint, or a corresponding flange is provided at the rear end of the connection section 11, so that the sealant delivery device 2 can pass through The bolts arranged on the flange realize the detachable connection. The connection section 11 and the insertion section 12 are coaxially connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com