Ink printing equipment for printing layers with many colours in one process

An ink printing, one-time technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve the problems of unfavorable product promotion and use, poor product quality, cumbersome operation, etc., and achieve rich learning, simple structure, and easy adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

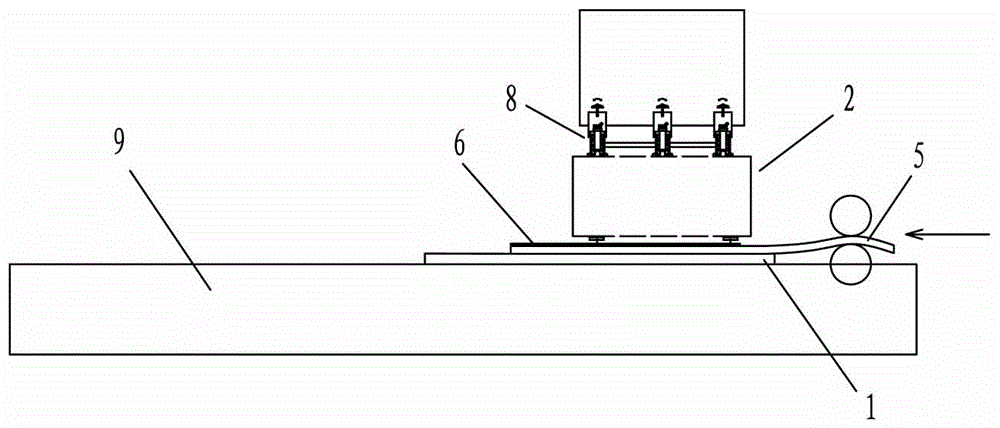

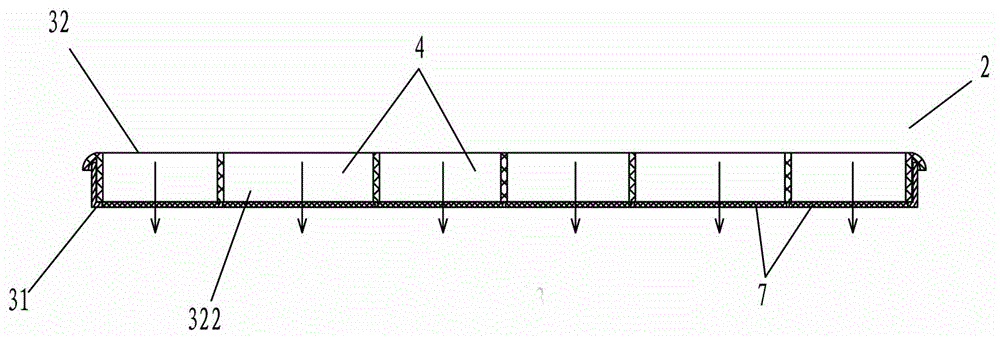

[0027] Such as Figure 1 to Figure 3 As shown, the ink printing equipment for printing multiple color layers at one time includes a printed body conveying part 1, an ink storage part 2 and a pressing device 8, and the ink storage part 2 is located above the printed body conveying part 1, and is characterized by , the ink storage part 2 includes an independent, detachable ink separation tray 3, the ink separation tray 3 is divided into a plurality of small compartments 4, and inks of different colors are stored in each small compartment 4 , apply ink layers 6 of different colors to the passing printed body 5 , and the pressing device 8 presses the ink separation disc 3 above the printed body conveying part 1 .

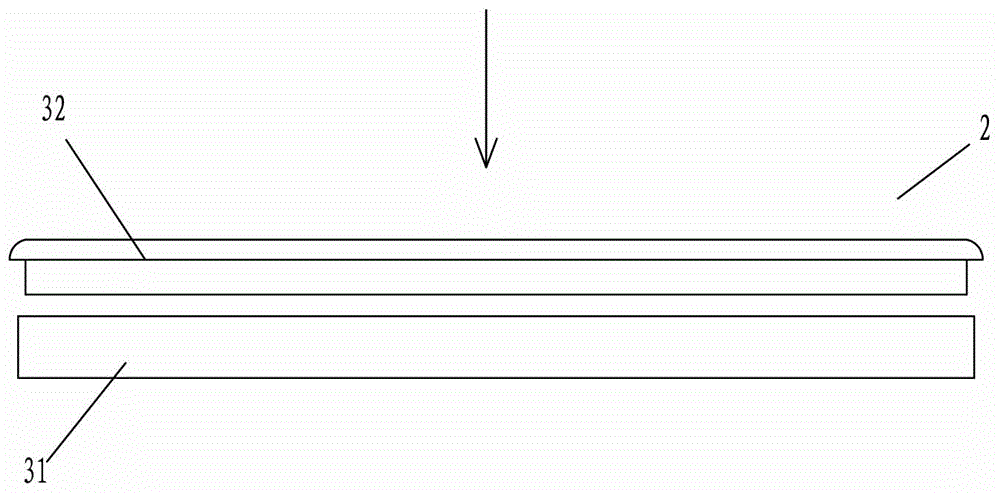

[0028] As a more specific solution, the ink separation tray 3 is a frame body, including a chassis 31 and a partition frame 32, the top and bottom of the partition frame 32 are open, and placed on the chassis 31, so that the chassis 31 is divided into A plurality of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com