Black-scale spring flat steel rolling technological method

A technology of spring steel and flat steel, which is applied in the field of ferrous metal rolling, can solve problems such as adverse effects on steel properties, achieve the effects of improving product surface quality, avoiding environmental corrosion, and simple and effective rolling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

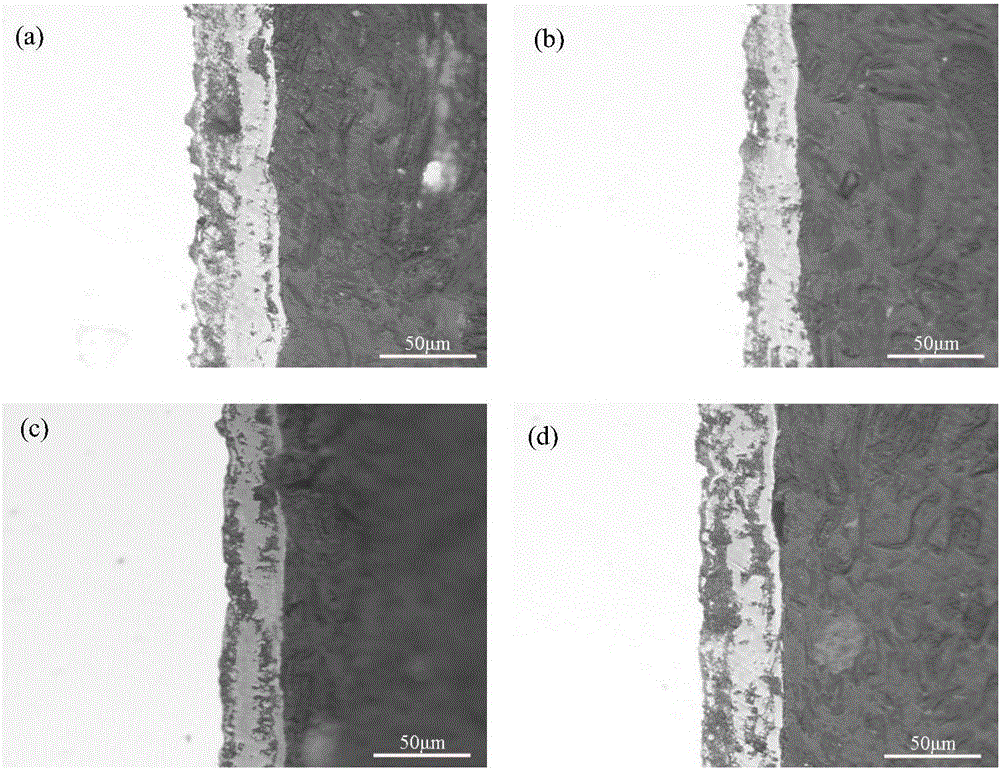

Image

Examples

Embodiment 1

[0027] Embodiment 1 rolling process:

[0028] Start rolling temperature / °C 1000, finish rolling temperature / °C 950, upper cooling bed temperature / °C 900, large shear temperature / °C 300, packaging temperature / °C 100, the temperature range from the upper cooling bed to about 550°C is 60°C / min cooling, and then cooling to the packaging temperature at 30°C / min for packaging.

Embodiment 2

[0029] Embodiment 2 rolling process:

[0030] Start rolling temperature / °C 1020, finish rolling temperature / °C 970, upper cooling bed temperature / °C 880, large shear temperature / °C 320, packaging temperature / °C 100, the temperature range from the upper cooling bed to about 550°C is 50°C / min cooling, and then cooling to the packaging temperature at 20°C / min for packaging.

Embodiment 3

[0031] Embodiment 3 rolling process:

[0032] Start rolling temperature / °C 1050, finish rolling temperature / °C 1000, upper cooling bed temperature / °C 900, large shear temperature / °C 350, packaging temperature / °C 120, the temperature range from the upper cooling bed to about 550°C is 50°C / min cooling, and then cooling to the packaging temperature at 15°C / min for packaging.

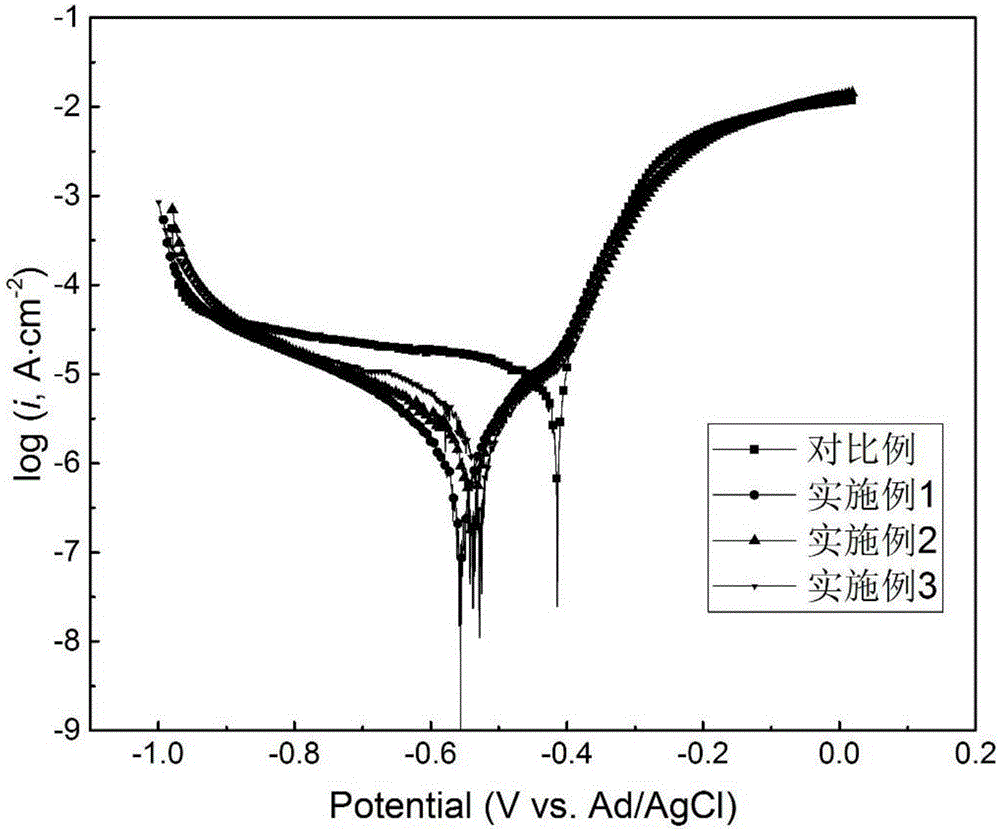

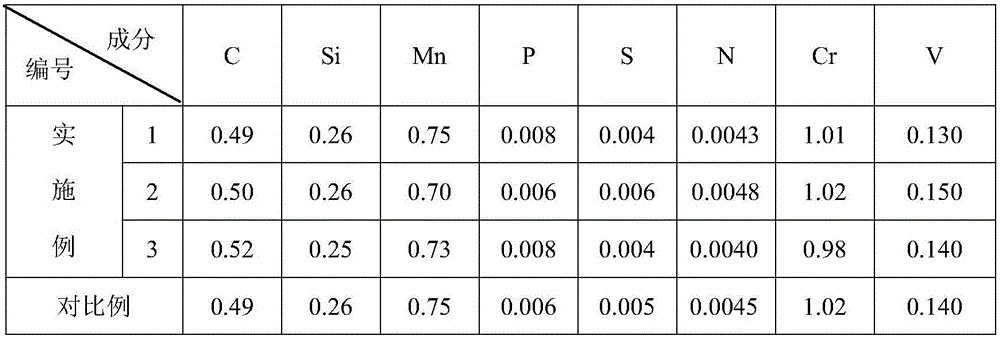

[0033] Table 1 embodiment and comparative example surface oxide skin electrochemical test result

[0034] rolling process Corrosion potential / V Self-corrosion current / (A / cm 2 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com