Front light module and display module

A front light module and display module technology, which is applied in the directions of optics, light guide, electric light source, etc., can solve the problems of limiting reflective display assembly, improvement, and display size increase, and achieves improved hot spots, good optical quality, and good Effect of Light Intensity Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

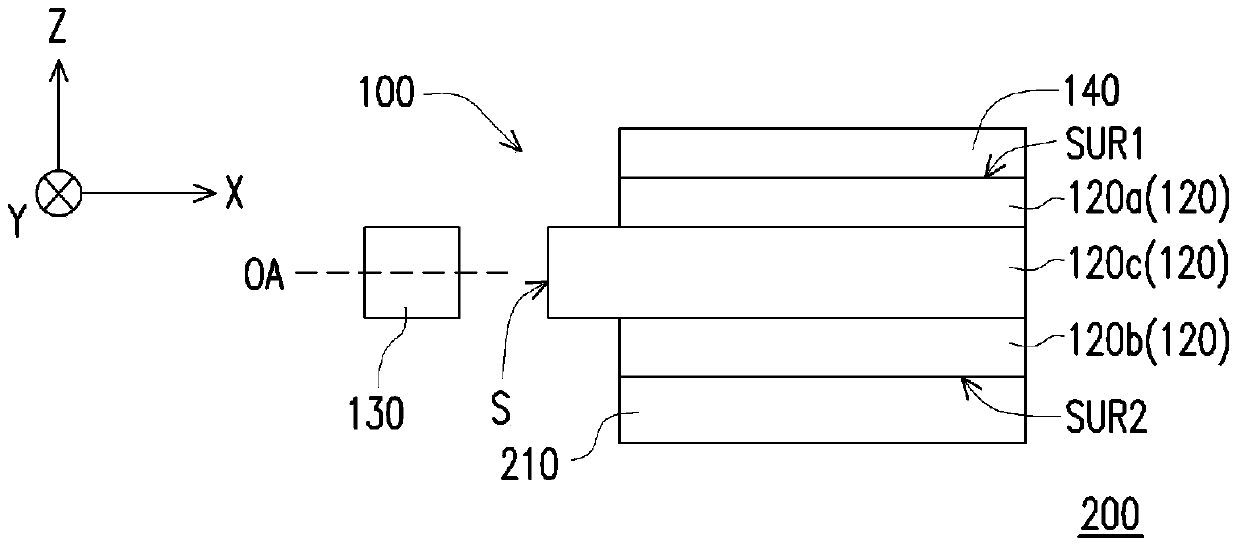

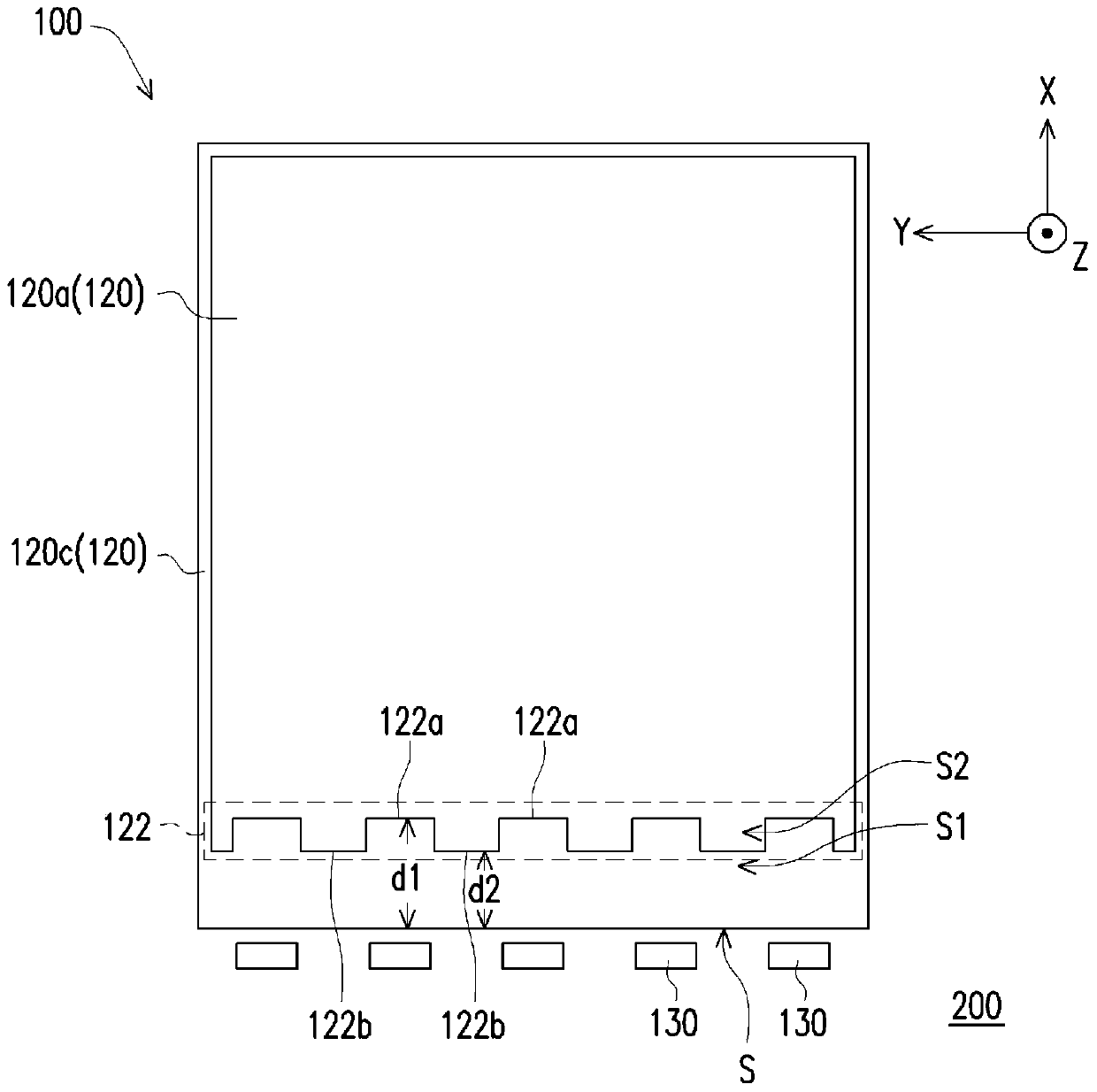

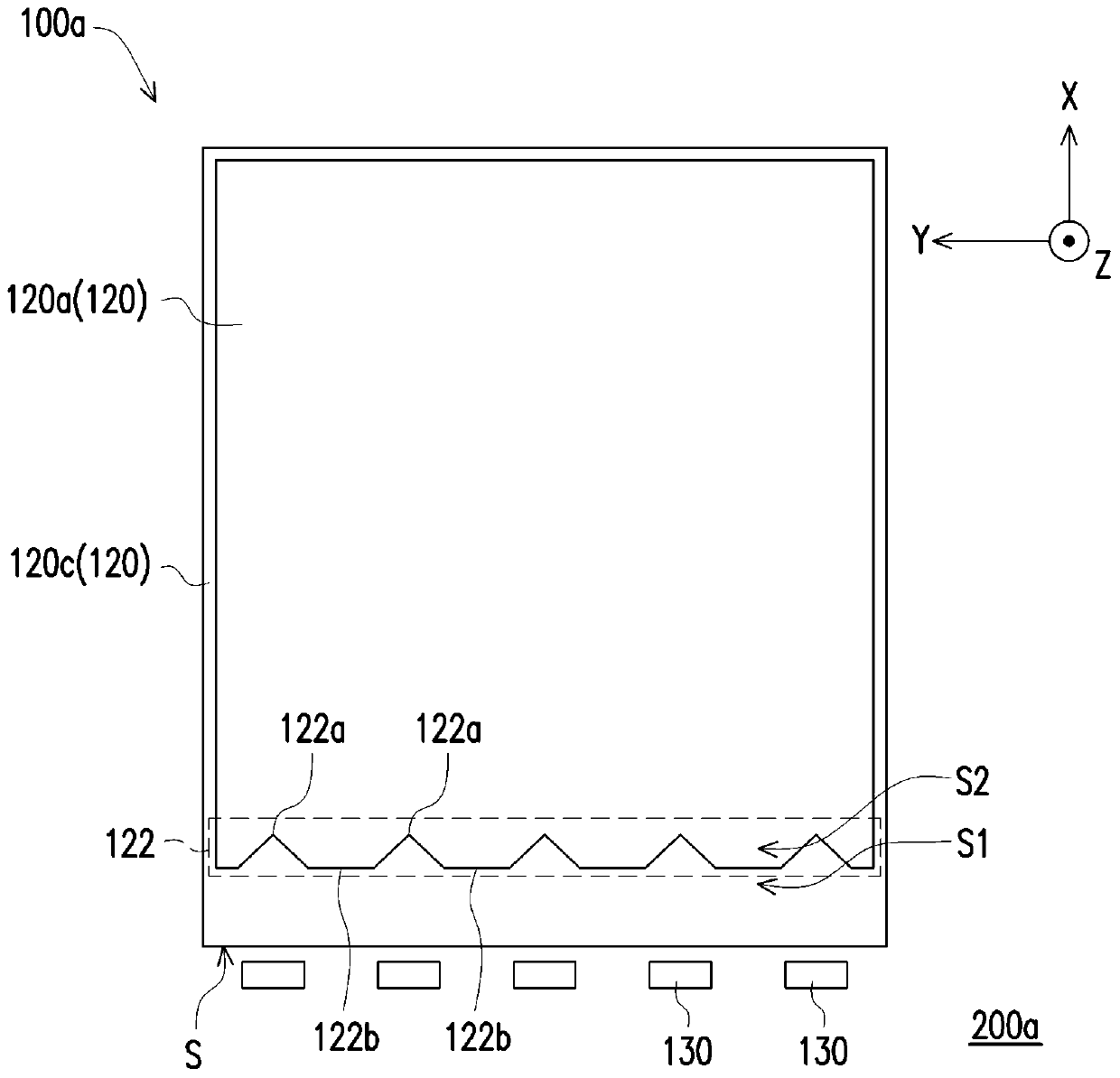

[0071] Figure 1A is a schematic cross-sectional view of a display module according to an embodiment of the present invention, Figure 1B for Figure 1A Example top view schematic. Figure 1C and Figure 1D They are schematic top views of display modules in different embodiments of the present invention. It should be noted that, in order to more clearly show the configuration relationship of the display modules in this embodiment, in Figure 1B The illustrated pattern of the functional layer 140 is omitted in FIG.

[0072] In order to describe the arrangement relationship of the display module 200 of this embodiment in detail, the display module 200 of this embodiment can be considered to be in a space constructed by the X axis, the Y axis and the Z axis, wherein the X axis direction is substantially the same as that of multiple axes. The directions of the optical axes OA of the light sources 130 are parallel and extend along the horizontal direction. The Z-axis direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com