A new electric drive cable detection device and detection method

A detection device and electric drive technology, applied in the direction of motor vehicles, testing metals, material inspection products, etc., can solve the problems of unstable operation, complex structure, low intelligence, etc., and achieve reliable work, simple structure, and avoid slippage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly highlight the objectives, technical solutions and advantages of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. This embodiment only enables the advantages and feasible solutions of the present invention to be understood by those skilled in the art, and does not limit the present invention and its applications or uses. Other embodiments derived from the present invention also belong to the present invention. The scope of technological innovation invented.

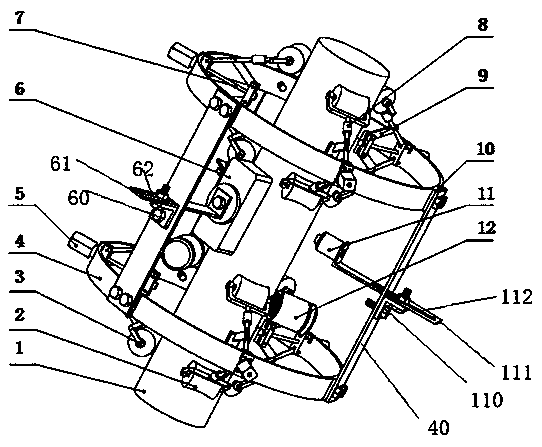

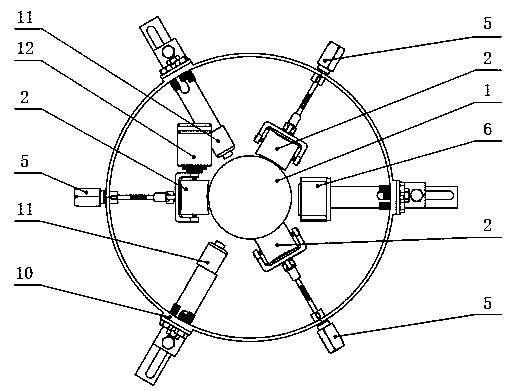

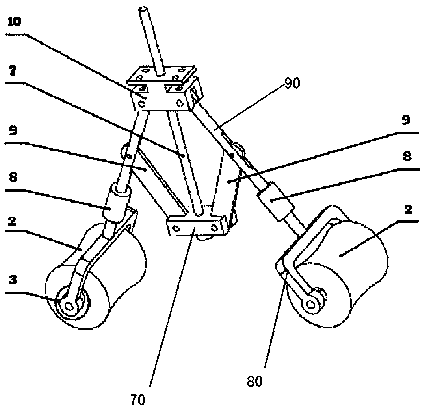

[0026] Such as Figure 1 to Figure 3 As shown, this embodiment provides a new type of electrically driven cable detection device, which includes a circular fixing frame 4, a connecting plate 40, a cable clamping sensor crawling device, a cable detection system and a control system.

[0027] There are two round fixing frames 4, which are arranged up and down in the axial direction. The connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com