Condensed water collector

A technology of condensate and collector, which is applied in the direction of instruments, steam condensation, thermoelectric condensation, etc., can solve the problems of interfering with the sampling process and damaging the components of the chamber, and achieve the effect that is not easy to make mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The chamber containing the condensate collector and the method of removing condensate from the chamber of the present invention will be discussed in more detail subsequently.

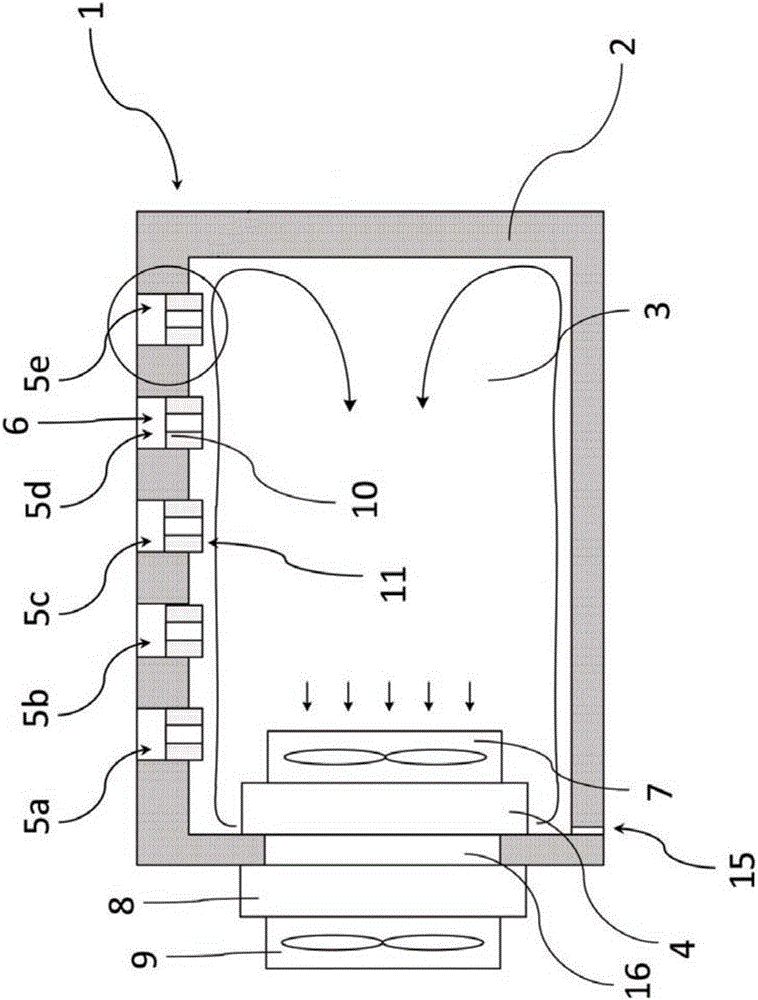

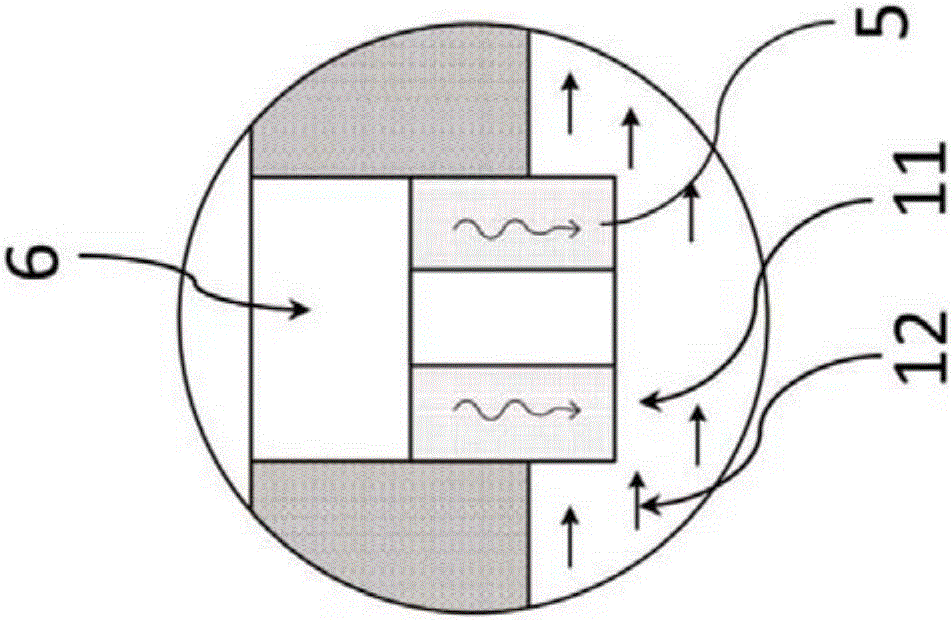

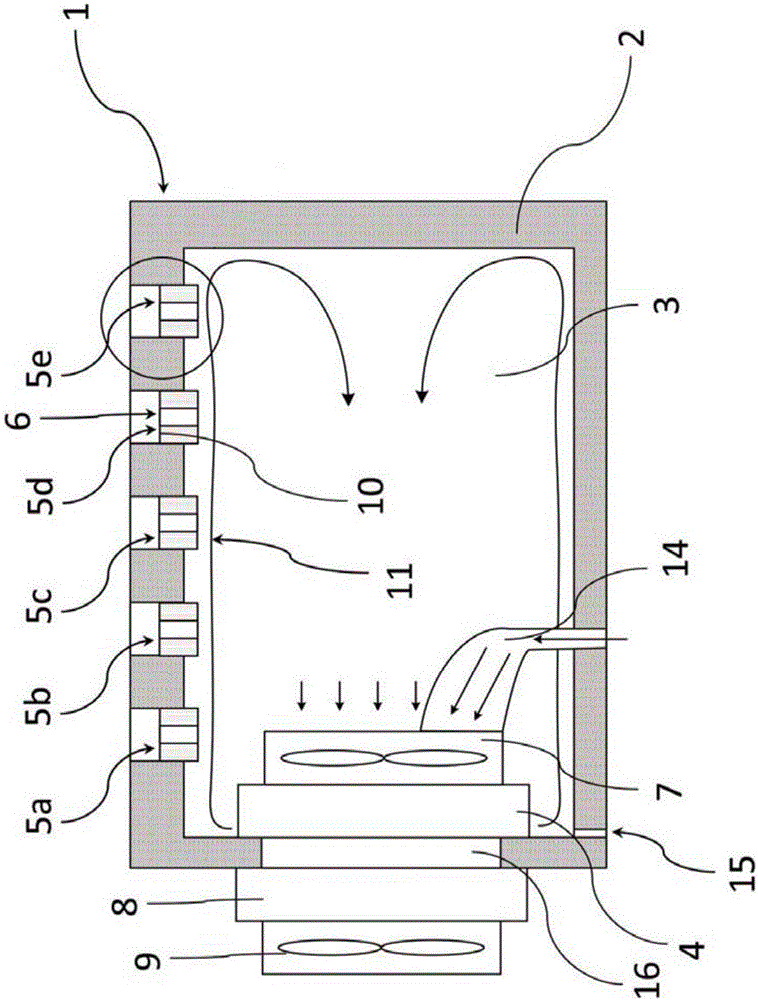

[0025] First, combine the Figure 1a and Figure 1b Different aspects of the chamber of the present invention are discussed. Then, combine the Figure 2a to Figure 6 Alternative or additional aspects of the chamber of the invention are detailed. Figure 1a The illustrated chamber 1 comprising at least one target area 6 prone to condensation water formation comprises at least one condensation water collector 5a-5e comprising at least one first part 10 and at least one second part 11 , the first part 10 is arranged to collect condensed water from the at least one target area, the second part 11 is outside the at least one target area, including being arranged between the first part 10 and the second part 11 and is configured to deliver the collected Porous material for condensed water, the chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com