Method and system for examining cutter compensation parameters based on numerical control machine

A tool compensation, CNC machine tool technology, applied in the field of control systems, can solve the problems of incorrect tool compensation parameters, machining accidents, etc., to prevent machining accidents, avoid negligence, and eliminate errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment discloses a method for verifying tool compensation parameters based on a numerically controlled machine tool, which is used to verify the correctness of tool compensation parameters.

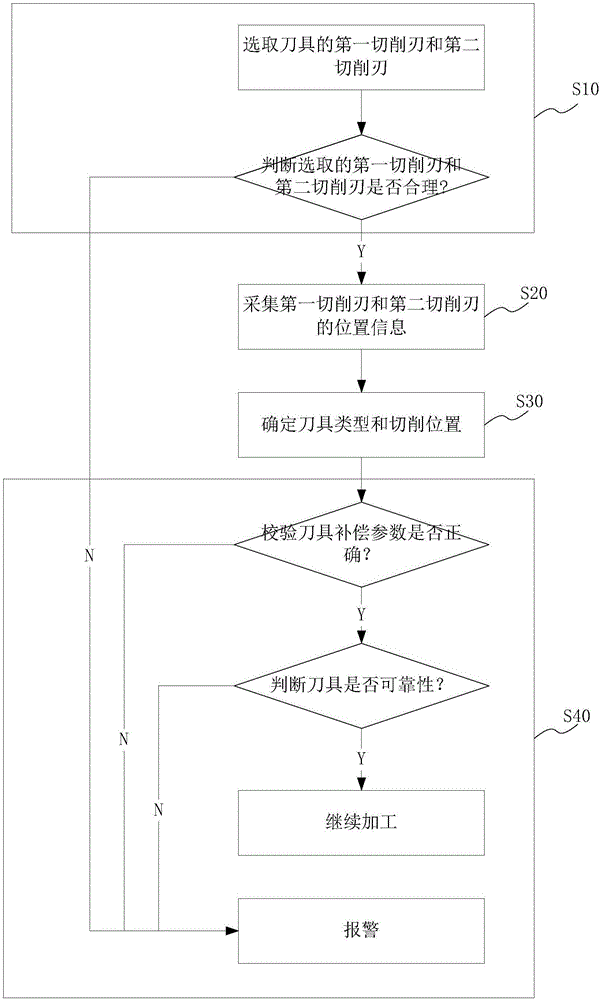

[0032] like figure 1 As shown, the verification method of the tool compensation parameters of the CNC machine tool of the present embodiment includes:

[0033] Step S10, select the first cutting edge and the second cutting edge of the tool:

[0034] Generally, it is stipulated that the lower cutting edge of the straight groove cutter of the vertical lathe is the first cutting edge; the cutting edge of the curved groove cutter is the cutting edge that can directly face the inner and outer circular surfaces as the preferred cutting edge, and the inner circle of the curved groove cutter The first cutting edge at the position is the right cutting edge; the first cutting edge at the outer circle position is the left cutting edge.

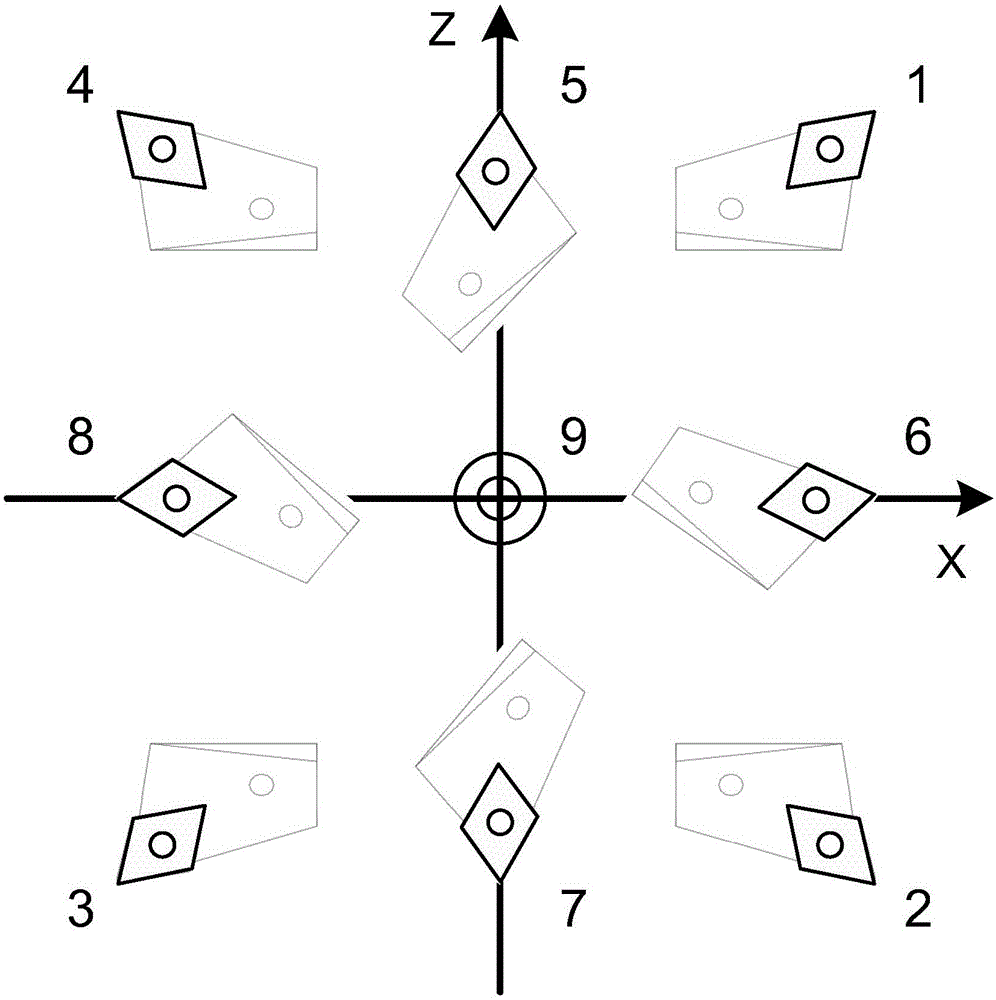

[0035] Among them, each cutting edge of the ...

Embodiment 2

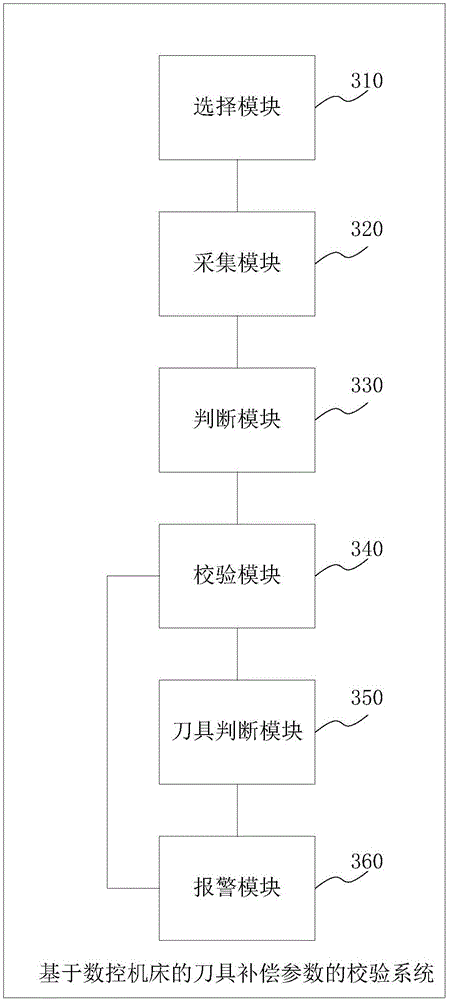

[0067] This embodiment discloses a calibration system for tool compensation parameters based on CNC machine tools, such as image 3 shown, including:

[0068] A selection module 310, configured to select the first cutting edge and the second cutting edge.

[0069] The collection module 320 is used to collect the position information of the first cutting edge and the second cutting edge, wherein the position information refers to the coordinate information of the tip of the cutting edge, the X coordinate is the X-direction parameter, and the Z coordinate is the Z-direction parameter.

[0070] The judging module 330 is configured to judge the tool type and cutting position according to the position information of the first cutting edge and the position information of the second cutting edge. Wherein, the tool type includes but not limited to straight groove cutter and curved groove cutter, and the cutting position includes but not limited to inner circle position and outer circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com