Cast-iron liner for electric rice cooker

A technology of electric rice cooker and cast iron, which is applied in the field of cast iron liner for electric rice cooker, can solve problems such as unsafety, and achieve the effects of cost reduction, good energy storage effect, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated and described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

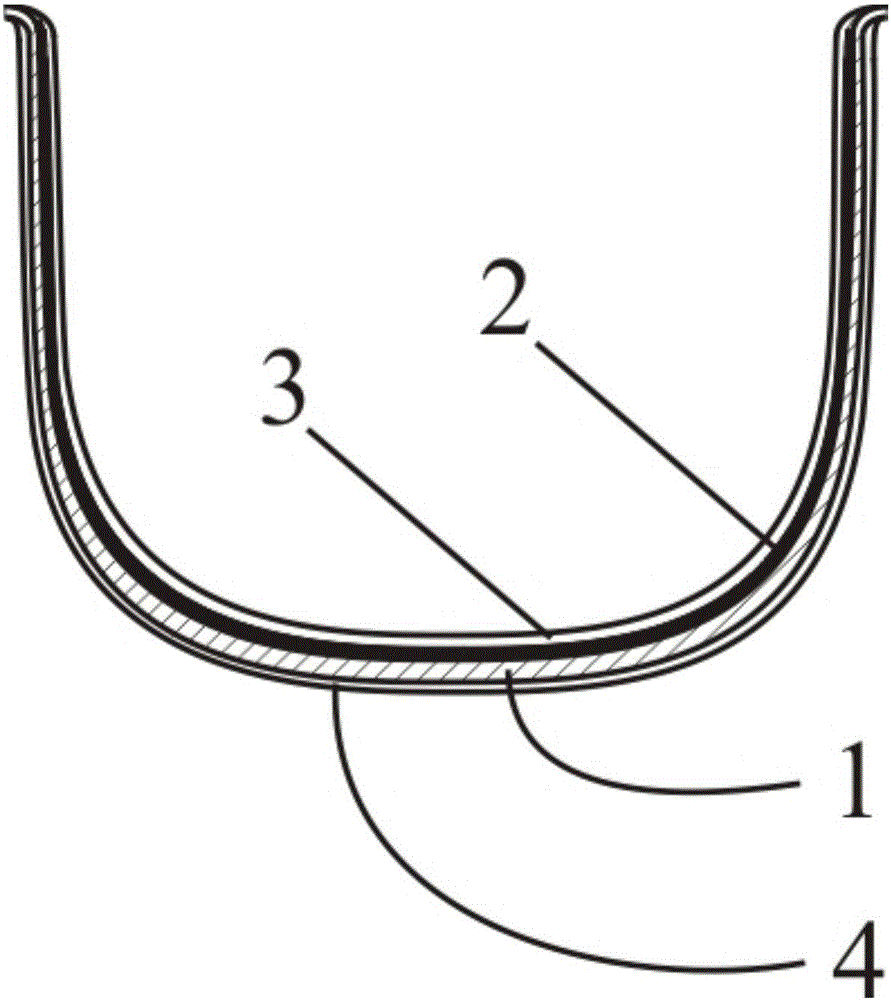

[0021] figure 1 It is a schematic structural view of a cast iron inner container for an electric cooker of the present invention, by figure 1 , the cast iron liner includes a main body 1, a nitrided layer 2, a non-stick coating 3 and a high-temperature paint 4; wherein, the main body 1 is a cylindrical shell designed to fit a rice cooker, and the bottom can be hemispherical or flat.

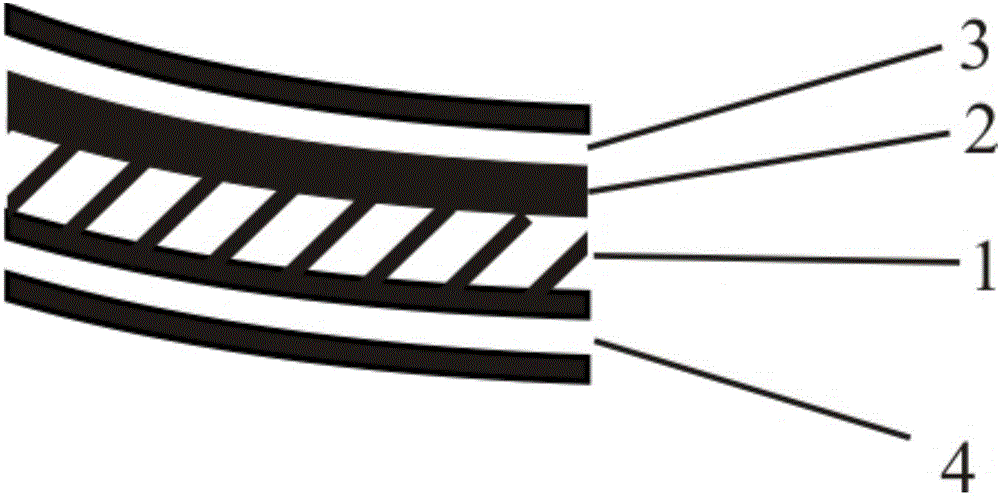

[0022] figure 2 It is a partially enlarged schematic diagram of the cast iron liner of the present invention, combined with figure 1 and figure 2 , the inner surface of the body 1 is the nitride layer 2 and the non-stick coating 3 from the outside to the inside, and the outer surface of the body 1 is the nitride layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap