Method for producing calcium gluconate and production device of method

A calcium gluconate and production device technology, applied in the field of calcium gluconate production, can solve problems such as high cost, large equipment investment, and large environmental pollution, and achieve the effects of fewer production processes, low production costs, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

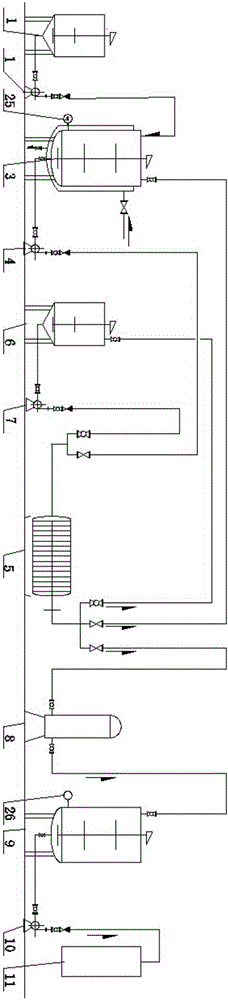

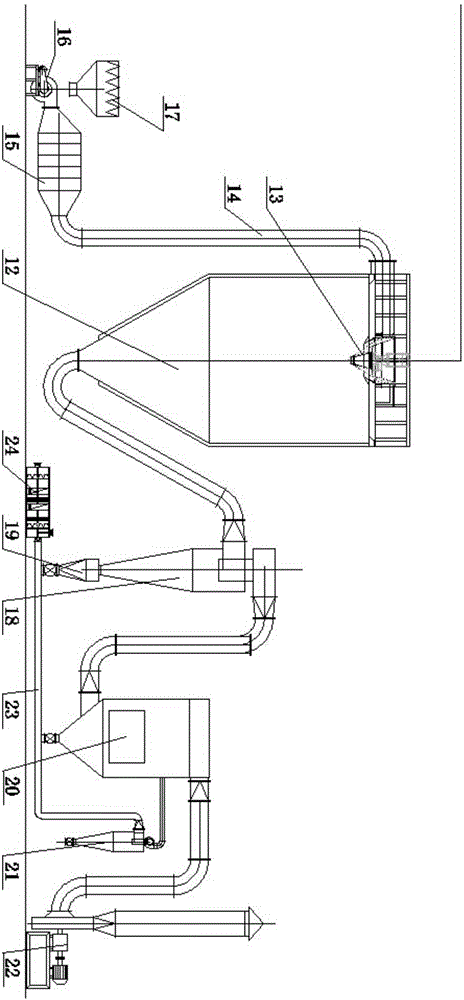

Image

Examples

Embodiment 1

[0028] A kind of method for producing calcium gluconate of embodiment 1, concrete steps are as follows:

[0029] (1) Neutralization reaction

[0030] Add gluconolactone into the batching tank, and add pure water or condensed water at the same time, so that the mass fraction of the gluconolactone solution is 18.5%, pump the prepared gluconolactone solution into the neutralization barrel, and stir , slowly add CaCO during stirring 3 , open the steam valve of the neutralization tank, use the jacket of the neutralization tank to slowly raise the temperature, control the temperature to 83 ° C, keep warm for 26 minutes, and the pH is 7.0 to obtain a calcium gluconate solution.

[0031] (2) Decolorization and filtration

[0032] After the neutralization reaction finishes, add gac in neutralization barrel, add-on is 0.4% (mass fraction), stirs, and rotating speed is 30 rev / mins, and temperature is 83 ℃, decolouring 35 minutes, obtains calcium gluconate solution; Add perlite, diatom...

Embodiment 2

[0041] A kind of method for producing calcium gluconate of embodiment 2, concrete steps are as follows:

[0042] (1) Neutralization reaction

[0043] Add gluconolactone into the batching tank, and add pure water or condensed water at the same time, so that the mass fraction of the gluconolactone solution is 16%, pump the prepared gluconolactone solution into the neutralization barrel, and stir , slowly add Ca(OH) during stirring 2 , open the steam valve of the neutralization tank, use the jacket of the neutralization tank to slowly heat up, control the temperature to 80°C, keep warm for 28 minutes, and the pH is 6.5 to obtain a calcium gluconate solution.

[0044] (2) Decolorization and filtration

[0045] After the neutralization reaction finishes, add gac in neutralization barrel, add-on is 0.35% (mass fraction), stirs, and rotating speed is 25 rev / mins, and temperature is 84 ℃, decolouring 32 minutes, obtains calcium gluconate solution; Add perlite, diatomaceous earth an...

Embodiment 3

[0054] A kind of method for producing calcium gluconate of embodiment 3, concrete steps are as follows:

[0055] (1) Neutralization reaction

[0056] Add gluconolactone into the batching tank, and add pure water or condensed water at the same time, so that the mass fraction of gluconolactone solution is 20%, pump the prepared gluconolactone solution into the neutralization tank, and stir , slowly add CaCO during stirring 3 , open the steam valve of the neutralization tank, use the jacket of the neutralization tank to slowly heat up, control the temperature to 85°C, keep warm for 22 minutes, and the pH is 7.5 to obtain a calcium gluconate solution.

[0057] (2) Decolorization and filtration

[0058] After the neutralization reaction finishes, add activated carbon in the neutralization barrel, the addition is 0.45% (mass fraction), stir, and the rotating speed is 35 rev / mins, and temperature is 84 ℃, decolouring 38 minutes, obtains calcium gluconate solution; Add perlite, dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap