Pouring type pile driver and pile driving method therefor

A pile driver and pouring technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of wasting resources, lagging production and construction period, increasing expenses, etc., to increase the bearing area, increase the contact area, The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

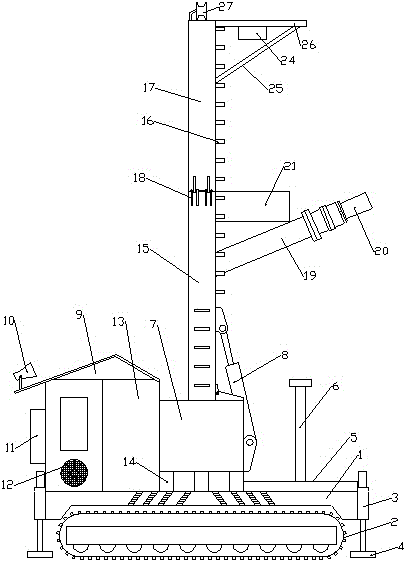

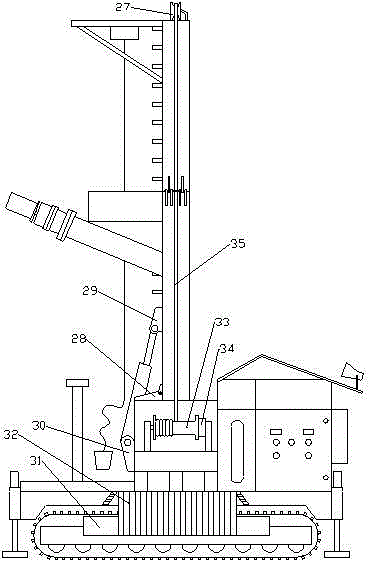

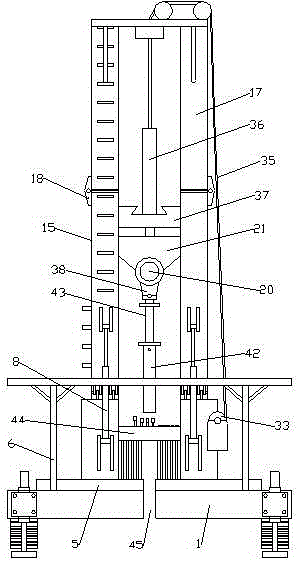

[0021] Such as figure 1 , 2 , 3, 4, 5, and 6, a pouring type pile driver, including a pile frame 1, a crawler wheel 2 installed below the pile frame 1, a support jack 3 arranged on the pile frame 1, a support jack 3 installed on the pile frame 1 The support plate 4 at the bottom, the guide frame 15 that is arranged on the pile frame 1, the hoist shaft 33 that is movably installed on the guide frame 15 one side, the hoist 24 that is connected with the hoist shaft 33 by the lifting rope 35, and the hoist 24 phase The connected oil pressure guide rod 36, the pile hammer 37 that is arranged on the bottom of the oil pressure guide rod 36, the top of the pile frame 1 is provided with a connecting frame 7, the connecting frame 7 is movably connected with the guide frame 15, and on one side of the connecting frame 7 An oil pressure control station 44 is arranged on the side, and the oil pressure control station 44 is connected with the oil pressure guide rod 36 through a conduit, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com