Noise reducing impeller and range hood applying impeller

A range hood, noise reduction technology, applied in the application, removal of oil fume, components of pumping devices for elastic fluids, etc., to achieve the effect of eliminating flow noise and reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

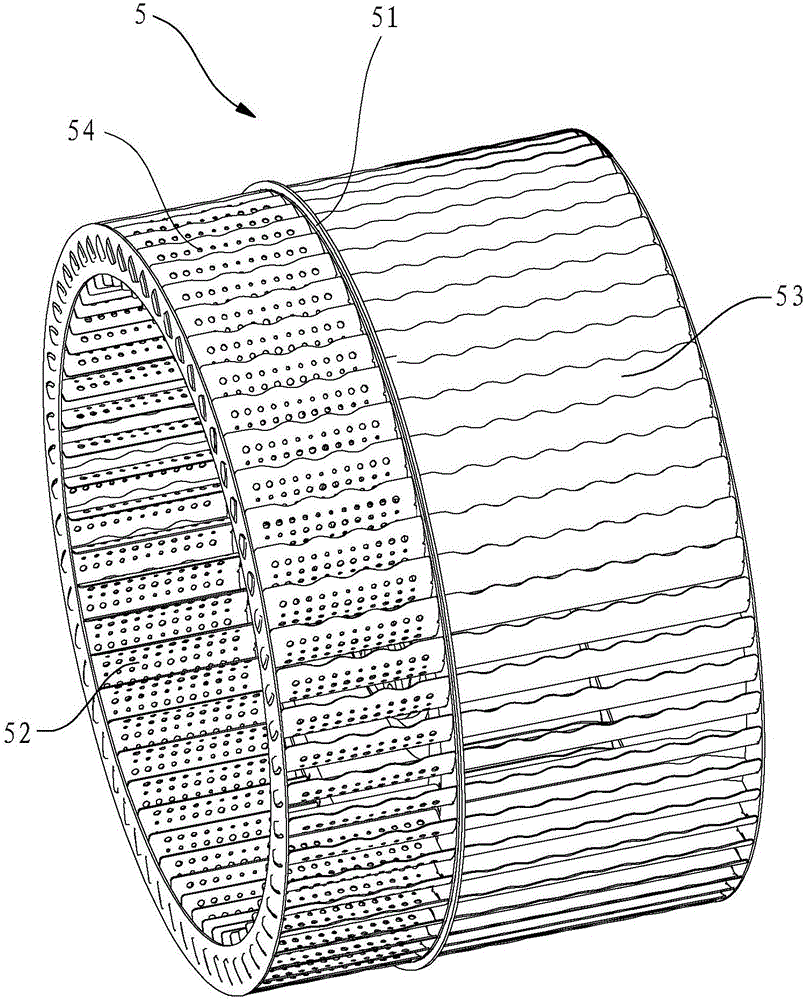

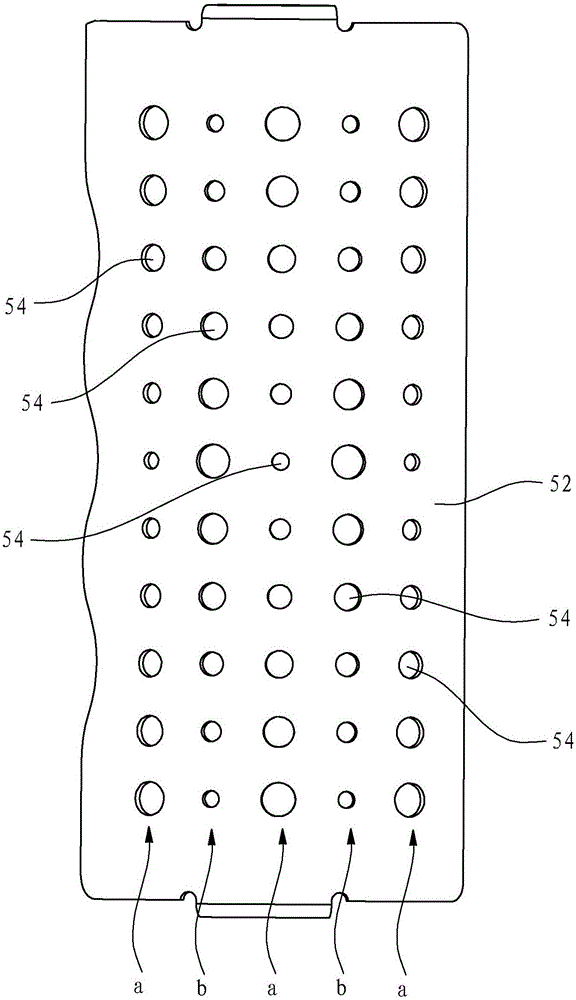

[0023] Such as figure 1 and figure 2 As shown, the noise reduction impeller 5 in this embodiment includes a middle plate 51 and blades installed on the middle plate, wherein the blades include front blades 52 arranged on the front side of the middle plate and rear blades 52 arranged on the rear side of the middle plate. For the side blades 53, the front blades 52 are shorter and the rear blades 53 are longer, and the front blades 52 and the rear blades 53 can adopt an integral structure or a split structure. Noise reduction holes 54 are opened on the front blade 52 , and the noise reduction holes 54 are arranged in rows along the length direction of the front blade 52 , and at least three rows of noise hole rows are distributed on one front blade 52 .

[0024] In this embodiment, five rows of noise reduction holes are arranged on one front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com