Hardware part defect detecting system and method

A technology for hardware parts and defect detection, applied in the directions of optical testing flaws/defects, measuring devices, material analysis by optical means, etc., can solve the problems of high consumption of human resources, secondary processing, waste of resources, etc., to improve production automation degree, saving manpower, material and financial resources, reducing the effect of false detection or missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

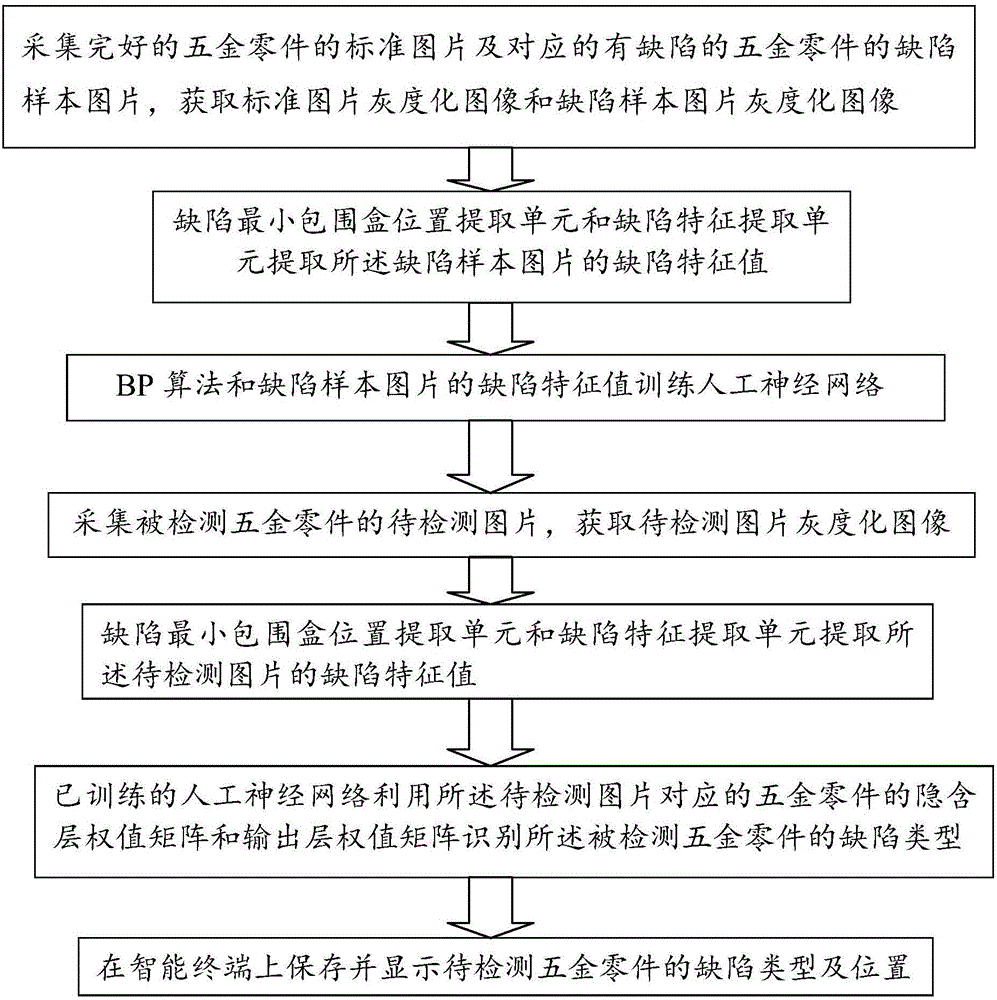

[0042] The invention provides a defect detection system for hardware parts, including an image acquisition module, a defect information extraction module, an artificial neural network training module, and a defect identification module;

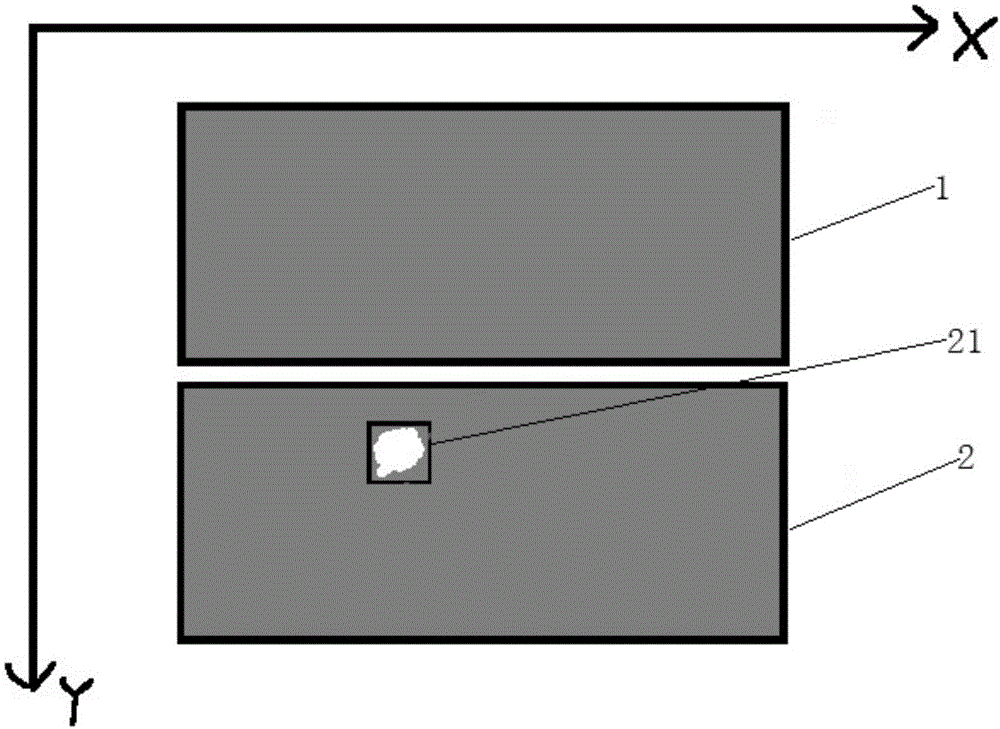

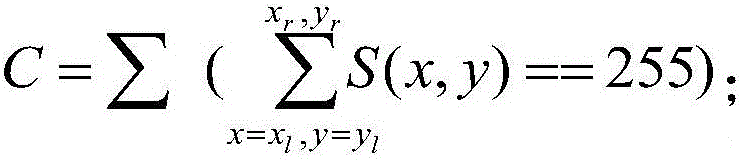

[0043] The image acquisition module is used to control the industrial camera to collect the standard picture of the intact hardware part and the defect sample picture of the corresponding defective hardware part, and carry out the definition of label and defect type to the defect sample picture; and the collected standard Image grayscale processing and image denoising processing are performed on the picture and the defect sample picture to obtain the grayscale ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com