Energy-saving drying method capable of improving qualities of dried abalones

An energy-saving and dried abalone technology, which is applied in the direction of dry preservation of meat/fish, food drying, food processing, etc., can solve the problems of large one-time investment of freeze-drying equipment, limitations of industrial application, uneven microwave radiation, etc., and achieve improvement Effects of sensory quality and rehydration, reduction of salt consumption, improvement of gel properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

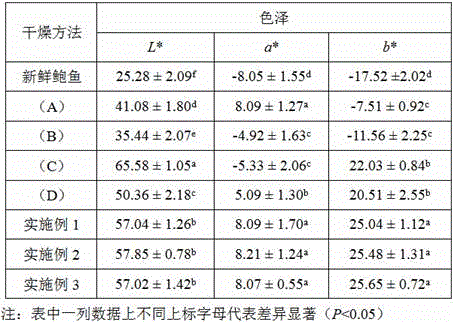

Embodiment 1

[0026] Select fresh live abalones, grade them according to specifications, and put them into live fresh ponds for temporary storage. The temperature of the cooling water system does not exceed 22°C, and the temporary storage time does not exceed 12 hours; wash off the sediment and stains on the surface of the abalone shells with clean sea water, and use a special Insert a round knife into the inner wall of the front end of the shell, cut off the meat column, take the meat out of the shell, and remove the viscera and film, then place the abalone meat in a drum machine, add sea salt at a mass ratio of 1:1, roll and knead to remove the edges of the abalone meat Melanin and mucus; put the abalone meat in an autoclave, inject an acidic electrolytic aqueous solution containing 0.5wt% sodium phytate and 2.5wt% sodium chloride, and control the mass ratio of the solution to the abalone meat at 2:1. Under high-pressure salting treatment for 10 minutes; then put the abalone meat in a radi...

Embodiment 2

[0028]Select fresh live abalones, grade them according to specifications, and put them into live fresh ponds for temporary storage. The temperature of the cooling water system does not exceed 22°C, and the temporary storage time does not exceed 12 hours; wash off the sediment and stains on the surface of the abalone shells with clean sea water, and use a special Insert a round knife into the inner wall of the front end of the shell, cut off the meat column, take the meat out of the shell, and remove the viscera and film, then place the abalone meat in a drum machine, add sea salt at a mass ratio of 1:1, roll and knead to remove the edges of the abalone meat Melanin and mucus; put abalone meat in an autoclave, inject an acidic electrolytic aqueous solution containing 1wt% sodium phytate and 2.5wt% sodium chloride, and control the mass ratio of the solution to abalone meat at 2:1, at 34°C and 100MPa High-pressure salting treatment for 10 minutes; then put the abalone meat in a ra...

Embodiment 3

[0030] Select fresh live abalones, grade them according to specifications, and put them into live fresh ponds for temporary storage. The temperature of the cooling water system does not exceed 22°C, and the temporary storage time does not exceed 12 hours; wash off the sediment and stains on the surface of the abalone shells with clean sea water, and use a special Insert a round knife into the inner wall of the front end of the shell, cut off the meat column, take the meat out of the shell, and remove the viscera and film, then place the abalone meat in a drum machine, add sea salt at a mass ratio of 1:1, roll and knead to remove the edges of the abalone meat Melanin and mucus; put abalone meat in an autoclave, inject an acidic electrolytic aqueous solution containing 1wt% sodium phytate and 2.5wt% sodium chloride, and control the mass ratio of the solution to abalone meat at 2:1, at 35°C and 100MPa High-pressure salting treatment for 10 minutes; then put the abalone meat in a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com