Manufacture method for appearance panel with greatly-changed local wall thickness

A technology of wall thickness change and manufacturing method, applied in the direction of coating, etc., can solve the problems of mold cost and injection molding cost increase, strength decrease, and the transition slope should not be too large, so as to achieve the effect of easy mold filling and reduced surface shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

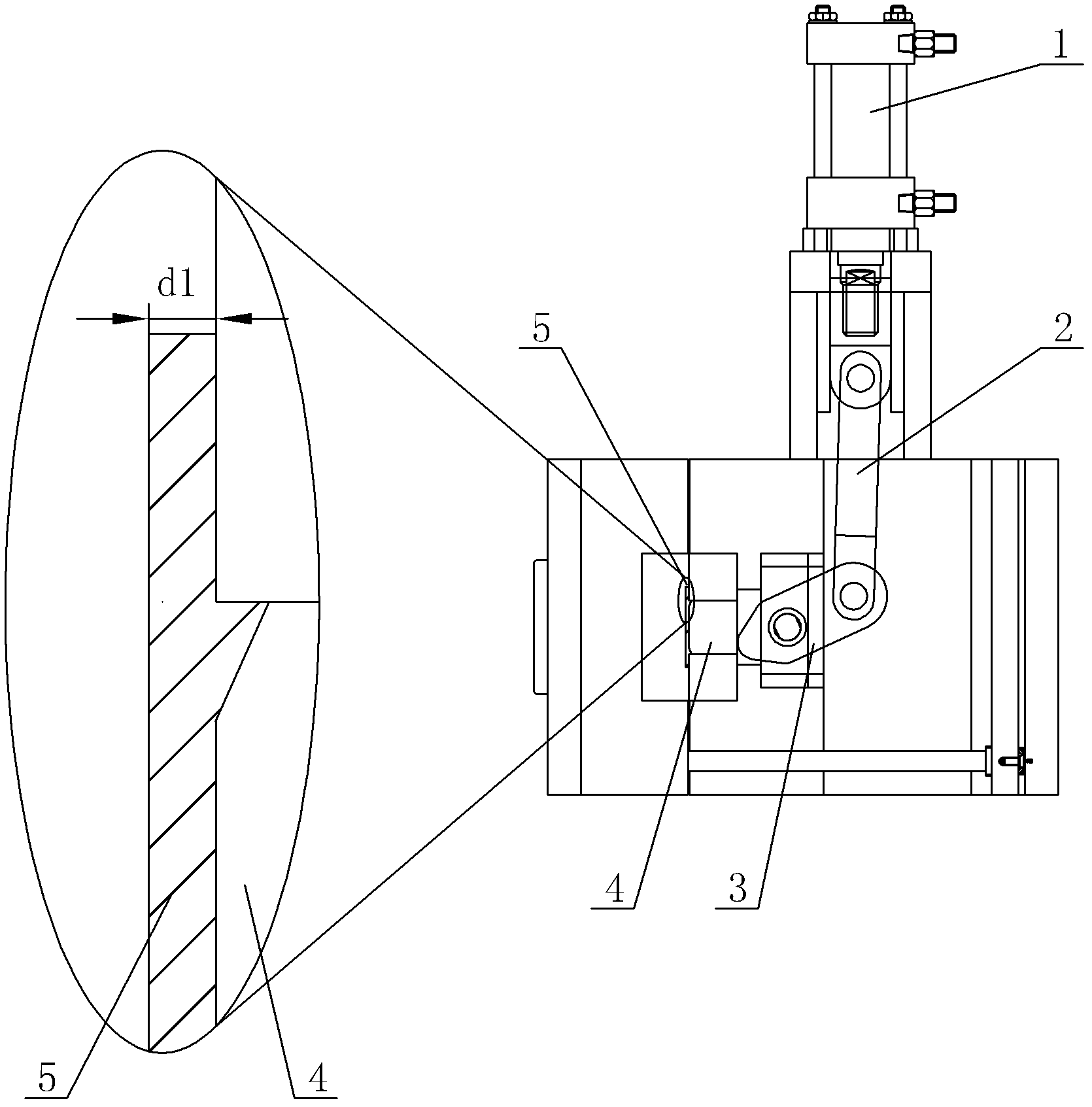

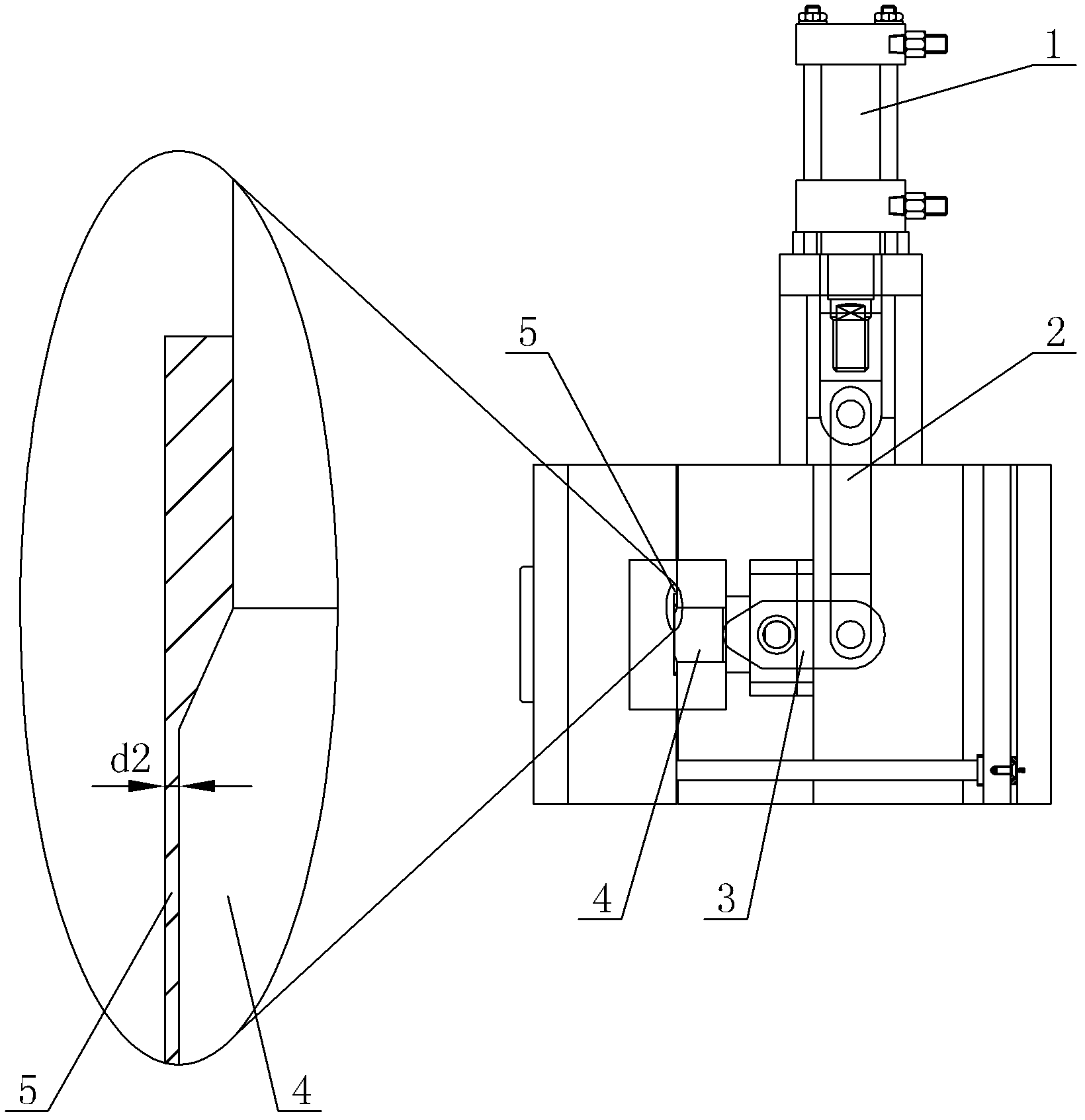

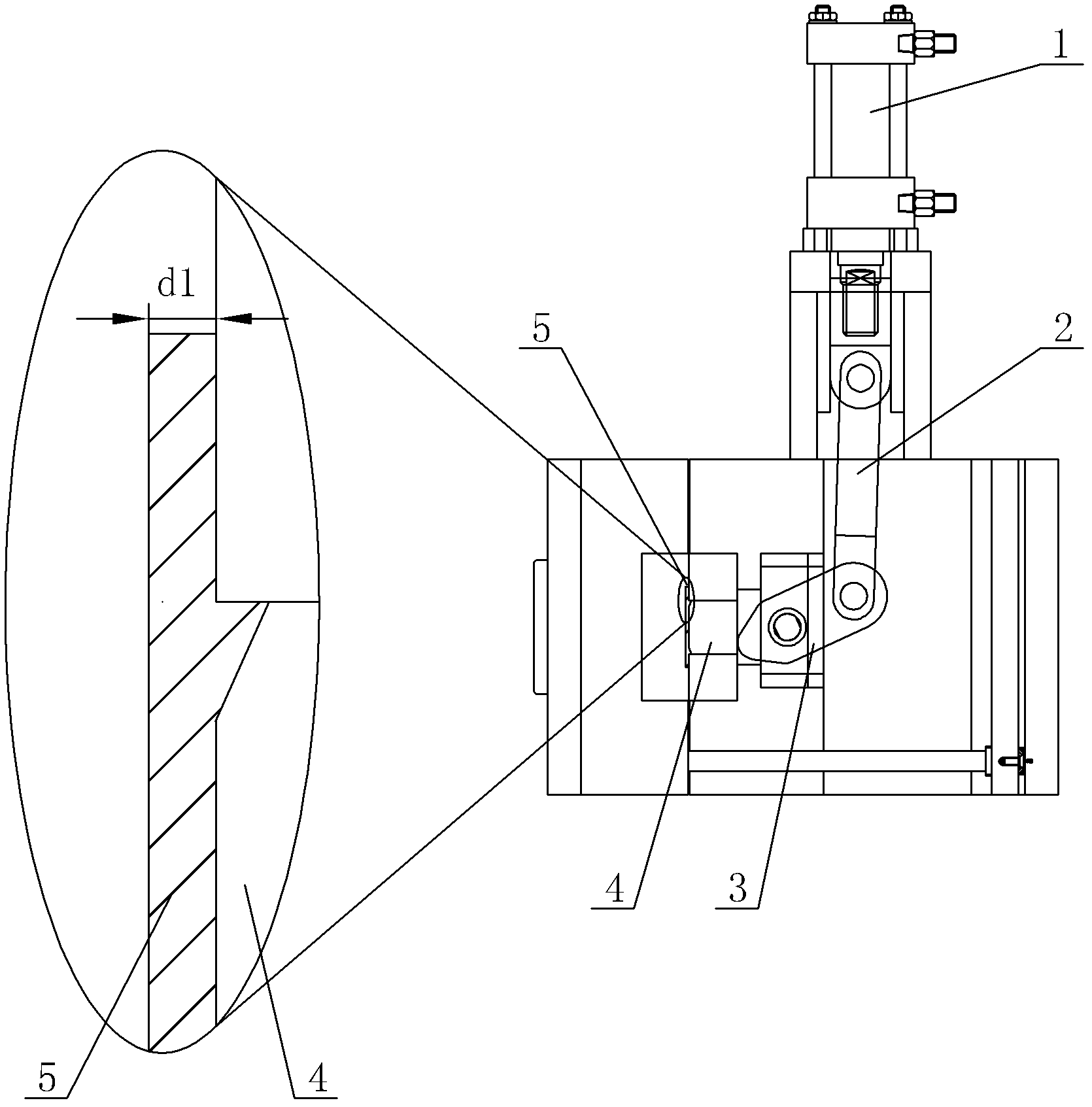

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] see Figure 1-Figure 2 , a method of manufacturing an appearance panel with a large local wall thickness variation, including a compression cylinder 1, a connecting rod 2, a cam 3, a compression block 4 and an injection molding cavity 5, the compression cylinder 1 is connected to the cam 3 through the connecting rod 2, and the cam 3 The top of the top is in contact with the compression block 4, and the compression block 4 is arranged on the back side of the appearance panel mold and can move back and forth. During the injection molding process, when the compression cylinder 1 drives the connecting rod 2 to move forward, the cam 3 pushes the compression block 4 to figure 2 Schematic position, at this time the compression block 4 will reduce the wall thickness of the corresponding part of the cavity 5 of the injection molded part. Before the sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com