Polyether-based maleimide copolymer and application thereof in concrete additive

A maleimide-like copolymer technology, applied in the field of polyether-based maleimide-like copolymers and its application in concrete additives, can solve the negative effects of concrete setting time, early and late strength, The plasticizing effect is not good, the water reducing effect is poor, and the plasticizing effect is remarkable, the equipment and reaction conditions are not harsh, and the water reducing efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

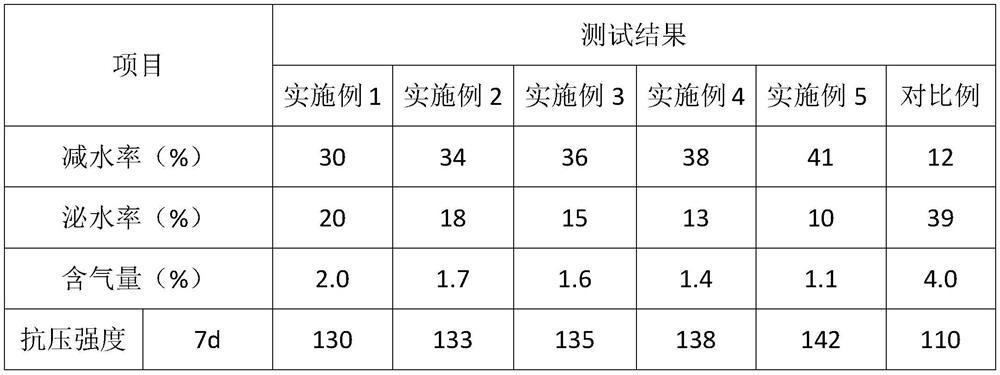

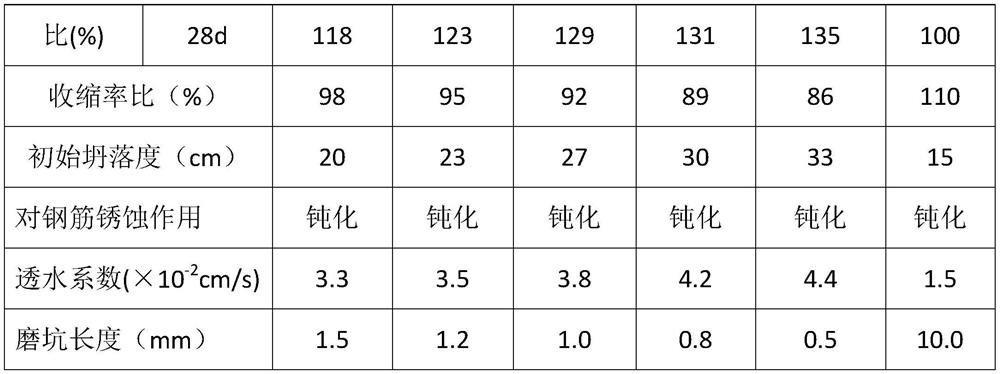

Examples

Embodiment 1

[0026] A concrete additive is prepared from the following components in parts by weight: 100 parts of polyether-based maleimide copolymer, 10 parts of sodium alginate and 1 part of modified wollastonite powder.

[0027] The polyether-based maleimide copolymer is composed of polyethylene glycol monoallyl ether, furo[3,4-d]-1,3-dioxole-2,4, 6-triketone, 4,4'-diaminostilbene-2,2'-disulfonic acid, maleimide-tris(ethylene glycol)-propionic acid prepared by free radical polymerization.

[0028] The preparation method of described polyether-based maleimide copolymer comprises the steps of: mixing polyethylene glycol monoallyl ether 10g, furo[3,4-d]-1,3-dioxa Cyclopentene-2,4,6-trione 5g, 4,4'-diaminostilbene-2,2'-disulfonic acid 10g, maleimide-tris(ethylene glycol)-propane Add 10 g of acid and 0.2 g of cumene hydroperoxide to 80 g of dimethyl sulfoxide, stir and react at 60°C for 3 hours under a nitrogen atmosphere, and then remove dimethyl sulfoxide by rotary evaporation to obtain ...

Embodiment 2

[0032] A concrete additive is prepared from the following components in parts by weight: 100 parts of polyether-based maleimide copolymer, 12 parts of sodium alginate and 2 parts of modified wollastonite powder.

[0033] The polyether-based maleimide copolymer is composed of polyethylene glycol monoallyl ether, furo[3,4-d]-1,3-dioxole-2,4, 6-triketone, 4,4'-diaminostilbene-2,2'-disulfonic acid, maleimide-tris(ethylene glycol)-propionic acid prepared by free radical polymerization.

[0034] The preparation method of described polyether-based maleimide copolymer comprises the steps of: mixing polyethylene glycol monoallyl ether 10g, furo[3,4-d]-1,3-dioxa Cyclopentene-2,4,6-trione 5g, 4,4'-diaminostilbene-2,2'-disulfonic acid 10g, maleimide-tris(ethylene glycol)-propane Add 10 g of acid and 0.25 g of cyclohexanone peroxide into 90 g of N,N-dimethylformamide, stir and react at 63°C for 3.5 hours under a helium atmosphere, and then remove N,N-dimethylformamide by rotary evaporatio...

Embodiment 3

[0038] A concrete additive is prepared from the following components in parts by weight: 100 parts of polyether-based maleimide copolymer, 13 parts of sodium alginate and 3 parts of modified wollastonite powder.

[0039]The polyether-based maleimide copolymer is composed of polyethylene glycol monoallyl ether, furo[3,4-d]-1,3-dioxole-2,4, 6-triketone, 4,4'-diaminostilbene-2,2'-disulfonic acid, maleimide-tris(ethylene glycol)-propionic acid prepared by free radical polymerization.

[0040] The preparation method of described polyether-based maleimide copolymer comprises the steps of: mixing polyethylene glycol monoallyl ether 10g, furo[3,4-d]-1,3-dioxa Cyclopentene-2,4,6-trione 5g, 4,4'-diaminostilbene-2,2'-disulfonic acid 10g, maleimide-tris(ethylene glycol)-propane Add 10 g of dicyclohexyl peroxydicarbonate and 0.3 g of N-methylpyrrolidone to 100 g of N-methylpyrrolidone, stir and react at 65 ° C for 4 hours under a neon atmosphere, and then remove N-methylpyrrolidone by rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com