Scissors handle

A scissors handle modification technology, applied in the field of scissors handles, can solve the problems of inability to guarantee scratch resistance, loss of impact resistance, scratch resistance, poor appearance and texture, etc., and achieve excellent scratch resistance and bright color Brilliant, no chromatic aberration balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

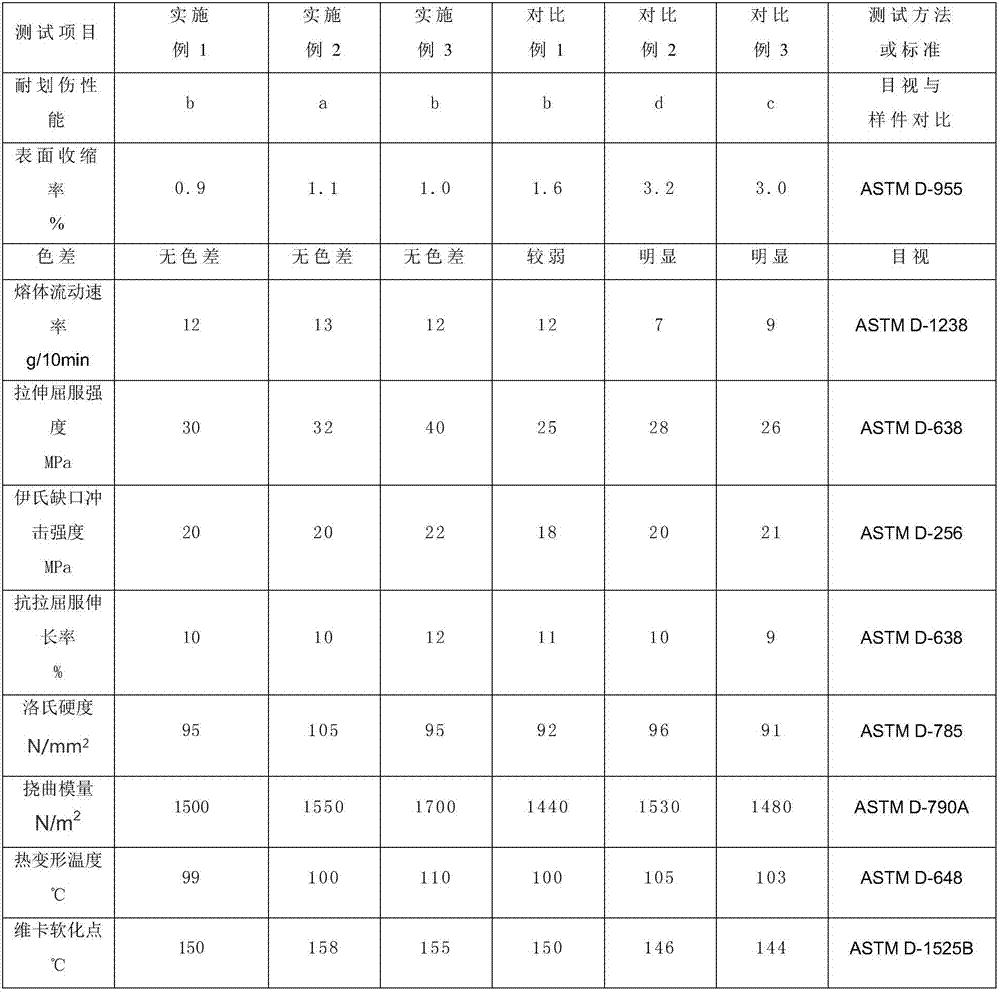

Examples

Embodiment 1

[0024] This embodiment provides a polypropylene modified composite material. The raw material formula of the composite material includes: polypropylene copolymer: 69%, calcium carbonate: 20%, antistatic agent: 4%, color masterbatch: 4%, auxiliary agent : 3%;

[0025] Copolymerized polypropylene (random copolymerized polypropylene polymerized from 1% of ethylene and 99% of propylene), having an average molecular weight of 3,500,000, was commercially available.

[0026] Calcium carbonate of 800 meshes was purchased commercially.

[0027] Antistatic agent (10% ethoxylated oleylamine and 10% ethoxylated stearylamine), commercially available.

[0028] The color masterbatch was purchased from Hong Kong Times Pigment Company, and the red color masterbatch was selected.

[0029] Auxiliary (ethylene bisstearic acid amide), commercially available.

[0030] The preparation method of polypropylene modified composite material is as follows:

[0031] Weigh 6.9kg of polypropylene copolym...

Embodiment 2

[0034] This embodiment provides a polypropylene modified composite material. The raw material formula of the composite material includes polypropylene copolymer: 75%, calcium carbonate: 18%, antistatic agent: 3%, color masterbatch: 3%, auxiliary agent: 1%;

[0035] Copolymerized polypropylene (random copolymerized polypropylene polymerized from 2% ethylene and 98% propylene), with an average molecular weight of 3,300,000, was commercially available.

[0036] Antistatic agent (ethoxylated oleylamine), commercially available.

[0037] Others are the same as embodiment 1.

Embodiment 3

[0039] This embodiment provides a polypropylene modified composite material. The raw material formula of the composite material includes polypropylene copolymer: 80%, calcium carbonate: 12%, antistatic agent: 2%, color masterbatch: 4%, auxiliary agent: 2%;

[0040] Copolymerized polypropylene (random copolymerized polypropylene polymerized from 3% ethylene and 97% propylene), with an average molecular weight of 3,000,000, was commercially available.

[0041] Antistatic agent (ethoxylated stearylamine), commercially available.

[0042] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com