Process method and device for by-product ethanol of partition column type methanol recovery column

The technology of a methanol recovery tower and a process method is applied in the field of by-product ethanol of a partition tower type methanol recovery tower, which can solve the problems of affecting the economic benefit of a methanol production device, increasing the amount of methanol loss, increasing production costs, and the like, and achieving remarkable practicability. And economic benefits, reducing methanol and ethanol content, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

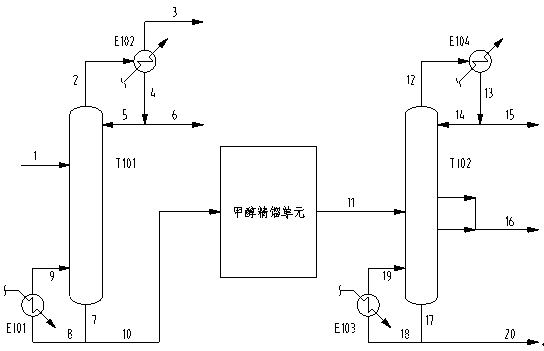

Embodiment 1

[0040] Such as figure 2 As shown, the crude methanol raw material 1 first enters the methanol rectification pre-column T101, discharges non-condensable gas 3 from the top of the tower and removes light components 6, and the prognostic crude methanol 10 obtained from the tower tank enters the methanol rectification unit, and undergoes methanol rectification The unit extracts refined methanol products, and the refined methanol liquid 11 discharged from the methanol rectification unit enters the methanol recovery tower T103.

[0041] A partition W101 is arranged at the lower part of the methanol recovery tower T103, and the partition W101 divides the lower part of the methanol recovery tower T103 into a methanol stripping side S101 and an ethanol stripping side S102, and the two sides are not connected to each other.

[0042] The dilute methanol liquid 11 from the methanol rectification unit is fed from the methanol stripping side S101, the methanol stripping side reboiler E103 ...

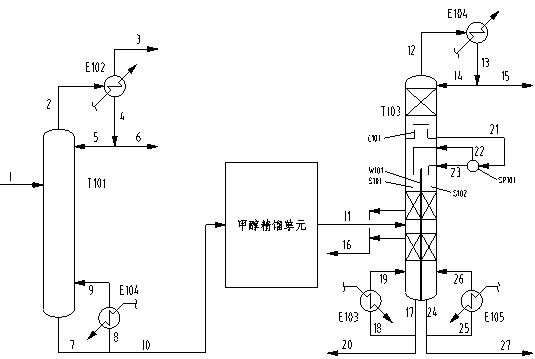

Embodiment 2

[0057] Such as image 3 shown, it is figure 2 An evolutionary process method, relatively figure 2 The process methods shown differ as follows:

[0058] The clapboard column methanol recovery tower T103 and the pre-column T101 are heat-integrated operations. The methanol vapor 12 at the top of the methanol recovery tower provides heat for the pre-column reboiler E101. The condensate 13 of the methanol vapor 12 is divided into two parts, one One strand returns to the top of the methanol recovery tower T103 as the reflux liquid 14 of the methanol recovery tower T103, and the other strand is extracted as the recovered methanol 15. The pre-column reboiler E101 does not require fresh steam heating, which greatly reduces the operating energy consumption of the entire methanol rectification.

[0059] Taking 1,000,000 tons / year of natural gas to produce U.S. federal standard "AA" level methanol plant as an example (operating hours are counted by 8000 hours / year), the process metho...

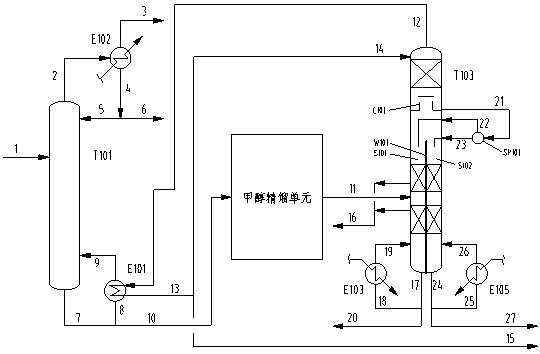

Embodiment 3

[0075] Such as Figure 4 shown, it is image 3 An evolutionary process method, relatively figure 2 The process methods shown differ as follows:

[0076] The bottom of the methanol stripping side S101 of the partition column methanol recovery tower does not use a reboiler, but uses direct steam 28 for heating.

[0077] The invention provides a process method and device for by-producing ethanol in a partition tower methanol recovery tower, which is a process method and device for realizing the by-production of ethanol while completing the methanol recovery process in the partition tower, which significantly reduces The content of methanol and ethanol in fusel oil can significantly increase the yield of methanol products, significantly reduce the energy consumption of the entire methanol distillation system, and at the same time produce ethanol by-products, which has significant practicality and economic benefits. It will be described in detail in conjunction with the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com