Stepless lifting device for scraper conveyor

A scraper conveyor and elevating device technology, applied in the field of mining equipment, can solve the problems of reduced height adjustment range, poor adaptability, poor hydraulic lifting stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

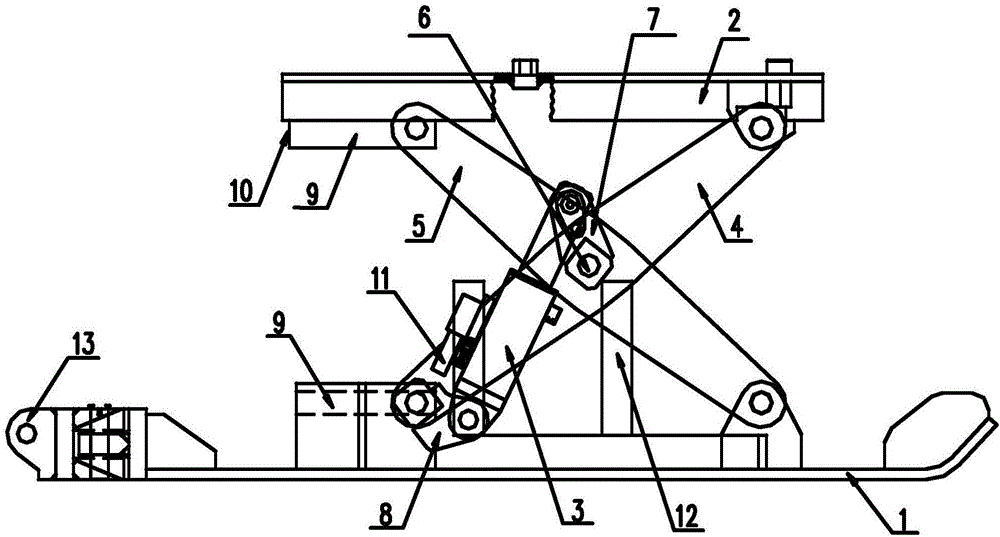

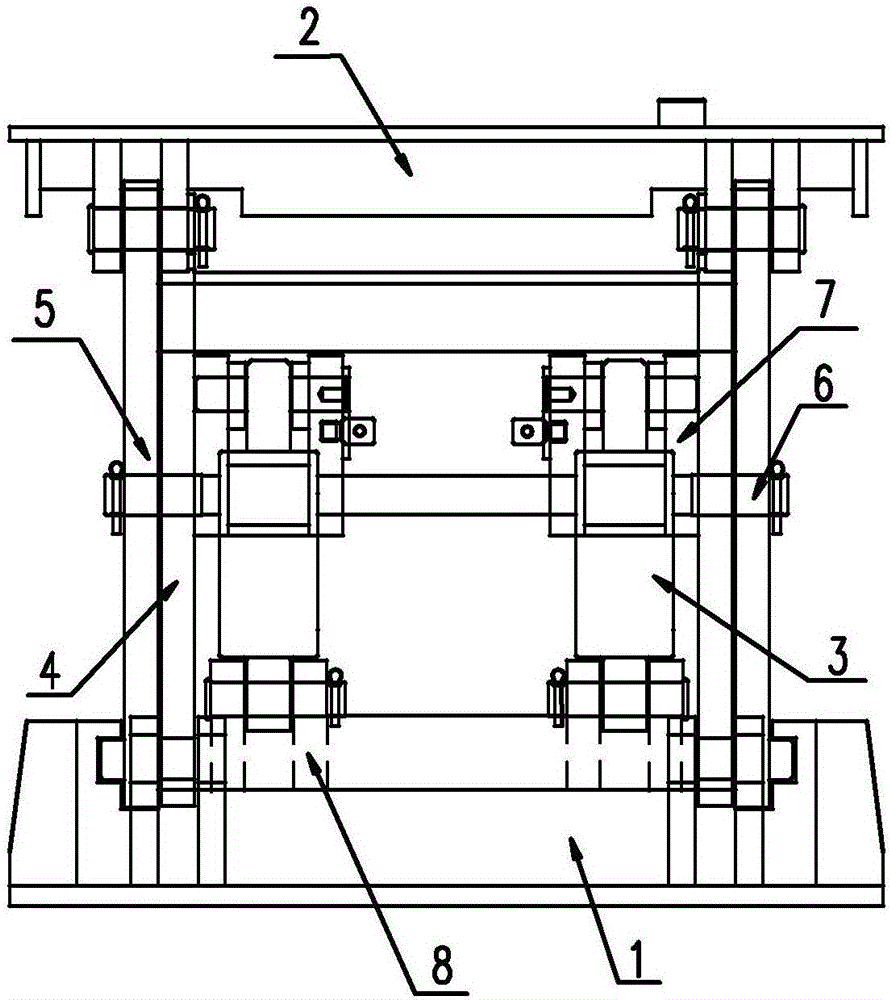

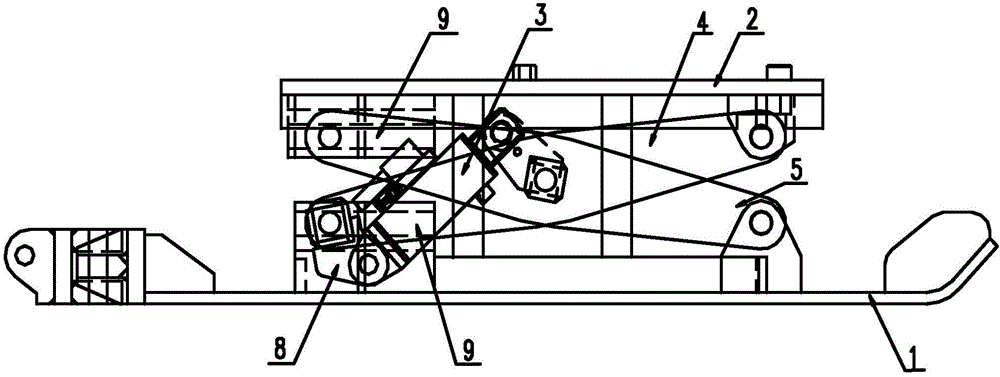

[0026] like Figure 1-3 As shown, a stepless lifting device for a scraper conveyor includes a base 1, a bearing platform 2, a hydraulic cylinder 3 and 2 sets of oppositely arranged working arms, and the hydraulic cylinder 3 is located between the base 1 and the bearing platform 2 , used to adjust the height of the lifting device, the top end of the working boom is hinged to the bearing platform 2, and the bottom end is hinged to the base 1. The bearing platform 2 is provided with threaded holes and positioning pins, which are used to connect the head, tail and transition groove of the scraper conveyor. The base 1 is configured as a shoe-lifting structure.

[0027] The working arm frame includes a first working arm 4 and a second working arm 5 arranged in a scissor-fork type, and the first working arm 4 and the second working arm 5 are hinged by a hinge shaft 6, and the hinge shaft 6 runs through 2 shafts respectively. Two groups of working booms are set opposite to each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com