Material supporting device and method

A technology of support rods and mounting holes, which is applied in the field of supporting devices before arc cutting of diaper machines, can solve the problems of affecting product quality and aesthetics, materials are prone to folding, and affecting production quality, so as to avoid machine operation performance Reduce, reduce material loss, simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

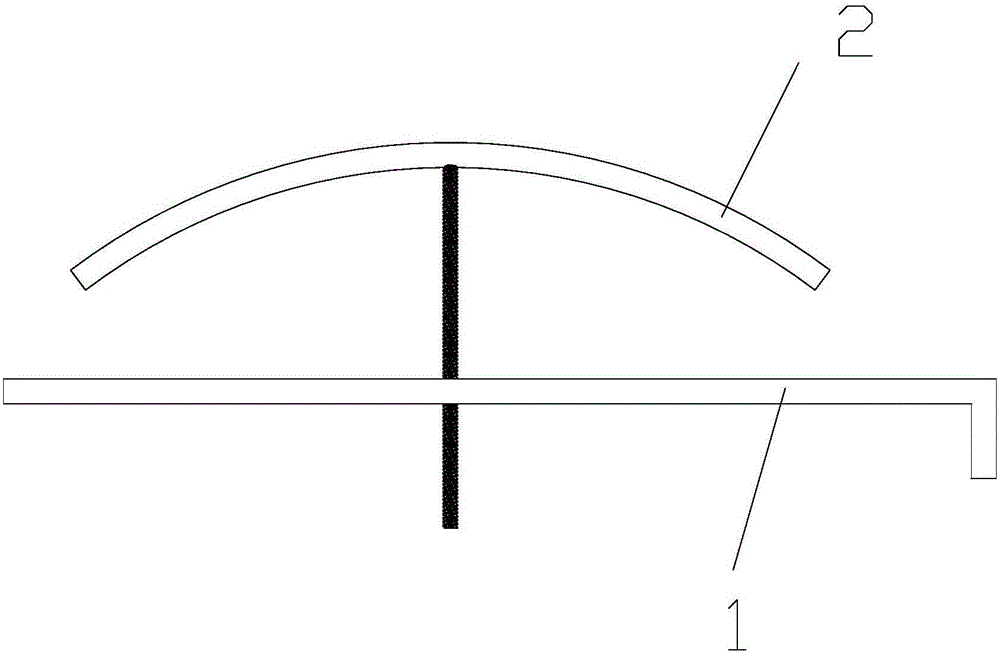

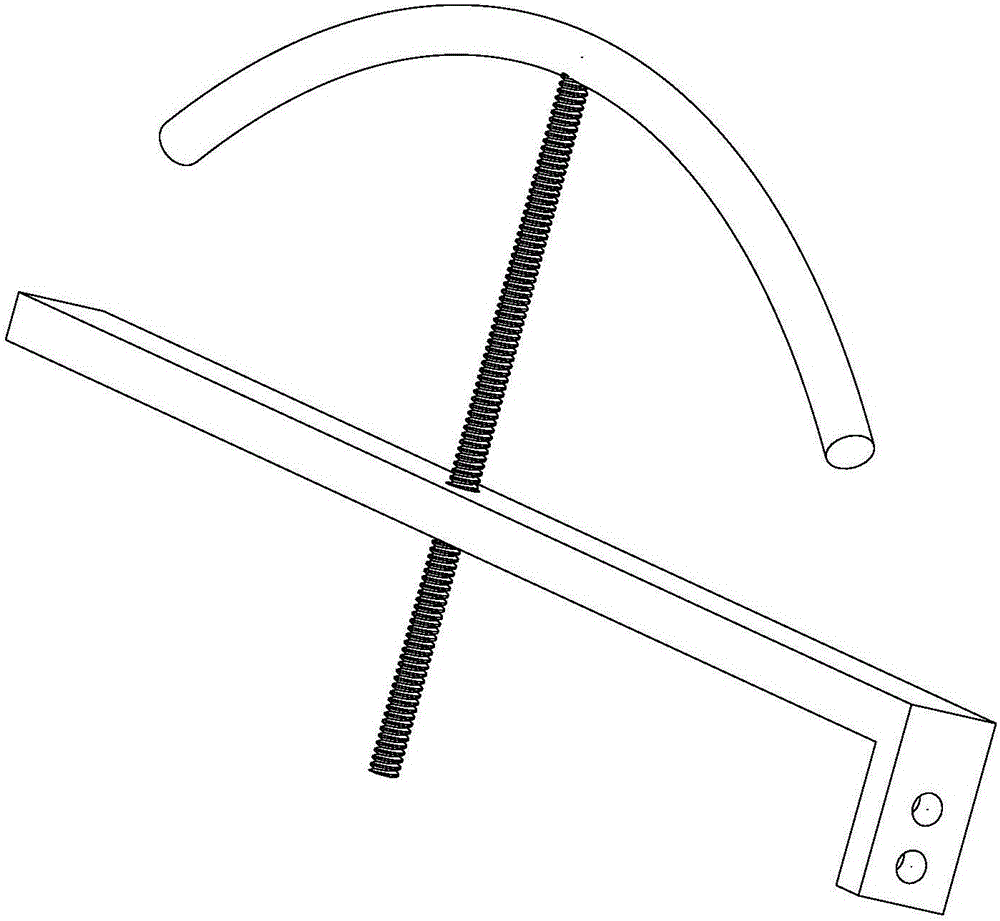

[0037] Embodiment 1: as Figure 1~4 , a support device, comprising a base 1 and a support mechanism 2 arranged on the base;

[0038] The supporting mechanism includes a support rod 22 and a curved part; the middle section of the curved part is connected with the support rod.

[0039] The curved part is an arc part 21 . The arc-shaped part is an arc-shaped tube; the weight is reduced to the greatest extent.

[0040] The base is provided with a socket 14 for inserting a support rod, and the support rod is a screw; the screw is fixed on the base by a nut.

[0041] Or the base is provided with a jack 14 for inserting a support rod, the jack is a screw hole, and the support rod is a screw; the screw is inserted into the screw hole and installed on the base.

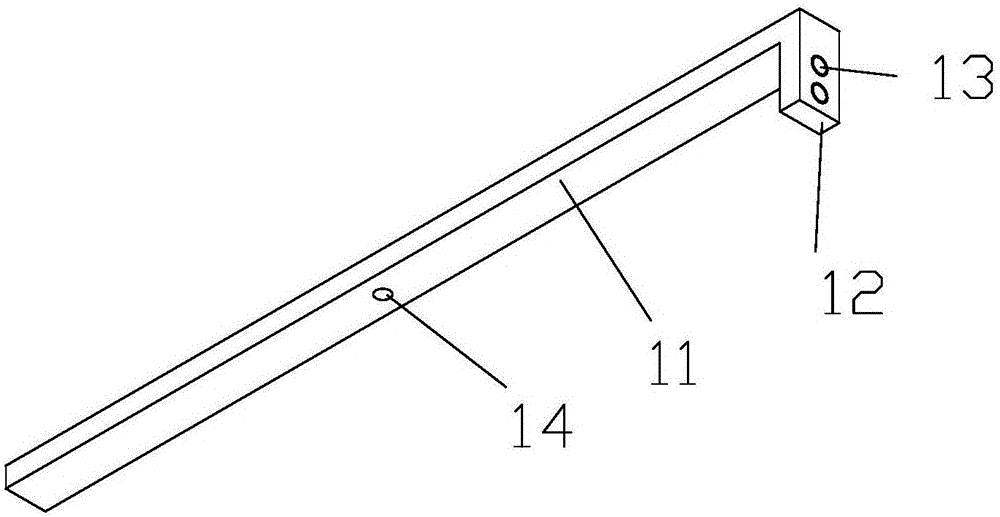

[0042] The base includes a base rod 11 and a connecting block 12 arranged at the end of the base rod.

[0043] At least one installation hole 13 is provided on the connection block. It is used to fix the base to other com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com