Catalyst for preparation of 1,3-propanediol from glycerin through hydrogenation as well as preparation method and application of catalyst

A technology for the preparation of catalysts and hydrogen, applied in metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve complex process, complicated reaction process, propylene glycol selectivity Low and other problems, to achieve the effect of low reaction temperature, low preparation cost and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

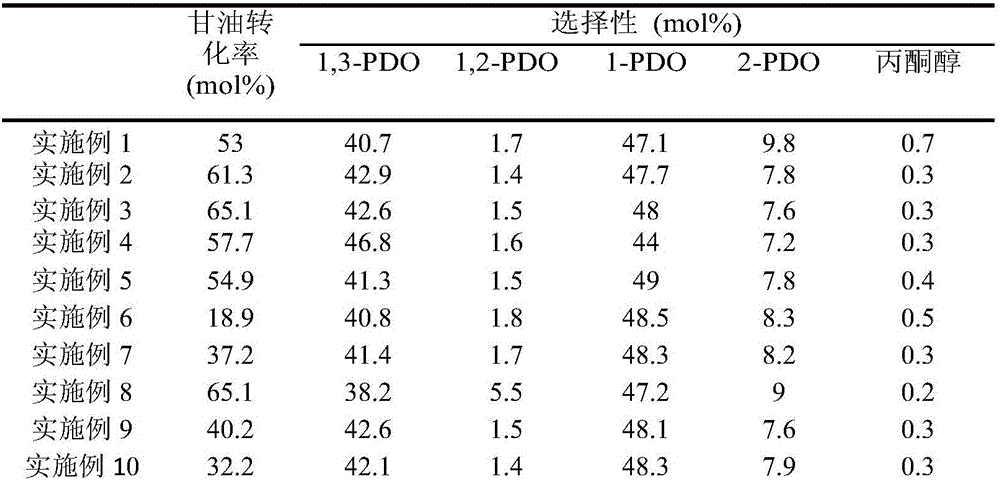

[0019] Example 1

[0020] Solid ZrO 2 The carrier is placed in a muffle furnace, raised to 650°C at a rate of 2°C / min, kept at a constant temperature for 2h, and cooled to room temperature to obtain ZrO 2 Forming carrier; weighing and measuring the formed ZrO 2 The carrier is immersed in the content of ammonium tungstate solution, vacuum shaken at 80°C, and dried in air at 110°C for 2h. The resulting sample is placed in a tube furnace, heated to 500°C at a rate of 2°C / min, kept at a constant temperature for 2h, and cooled to room temperature. Get WO 3 / ZrO 2 ; Weigh the WO prepared above 3 / ZrO 2 , Immerse in a certain content of ammonium niobium oxalate solution, vacuum and shake at 80°C to dry, and air dry at 110°C for 2h. Place the resulting sample in a tube furnace, heat up to 500°C at a rate of 2°C / min, keep the temperature for 2h, and cool to room temperature , Get a series of Nb 2 O 5 / WO 3 / ZrO 2 Sample; accurately measure a certain concentration of H with a pipette 2 PtCl...

Example Embodiment

[0022] Example 2

[0023] Pt-Nb was prepared by a step-wise impregnation method similar to that in Example 1. 2 O 5 / WO 3 / ZrO 2 Catalyst (including Pt content 2.0%wt, Nb 2 O 5 Content 0.8%wt, WO 3 Content 4.5%wt). 6g Pt-Nb 2 O 5 / WO 3 / ZrO 2 The catalyst is placed in a fixed bed reactor, a 10wt% glycerin aqueous solution is passed through, the hydrogen flow rate is controlled to be 50ml / min, the reaction temperature is 135°C, and the reaction pressure is 2.5MPa. During the reaction, samples were taken every 2h for analysis in a gas chromatograph. (Results are shown in Table 1)

Example Embodiment

[0024] Example 3

[0025] Pt-Nb was prepared by a step-wise impregnation method similar to that in Example 1. 2 O 5 / WO 3 / ZrO 2 Catalyst (including Pt content 2.0%wt, Nb 2 O 5 Content 1.0%wt, WO 3 Content 4.5%wt). 6g Pt-Nb 2 O 5 / WO 3 / ZrO 2 The catalyst is placed in a fixed bed reactor, a 10wt% glycerin aqueous solution is passed through, the hydrogen flow rate is controlled to be 50ml / min, the reaction temperature is 135°C, and the reaction pressure is 2.5MPa. During the reaction, samples were taken every 2h for analysis in a gas chromatograph. (Results are shown in Table 1)

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap