A kind of production technology of benzotriazole ultraviolet absorber uv1130

A UV1130 and benzotriazole technology is applied in the production process field of benzotriazole ultraviolet absorber UV1130, which can solve the problems of low reaction temperature, low final product yield and high production cost, and achieves improved reaction purity, The effect of saving energy consumption and suppressing the occurrence of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

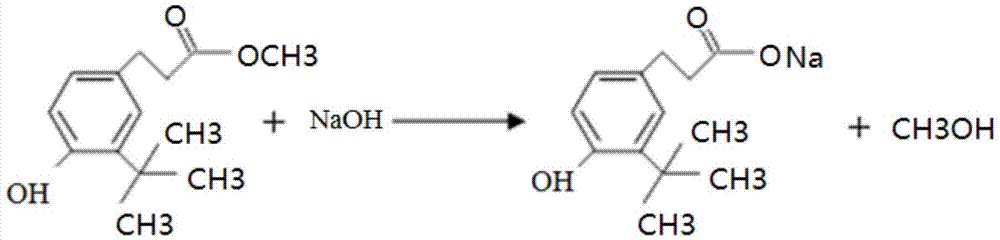

[0079] Put 280g of 3-tert-butyl methyl p-hydroxyphenylpropionate into the hydrolysis kettle, put 326g of 30% liquid caustic soda into the kettle from the liquid caustic soda metering tank, close the reaction kettle, and raise the temperature to 85°C for reflux reaction under normal pressure At the same time, the methanol produced by the reaction is evaporated, and after condensation, it is put into the methanol receiving tank. After the reaction is completed for 2 hours, it is left to stand, and the material is transferred to the coupling kettle;

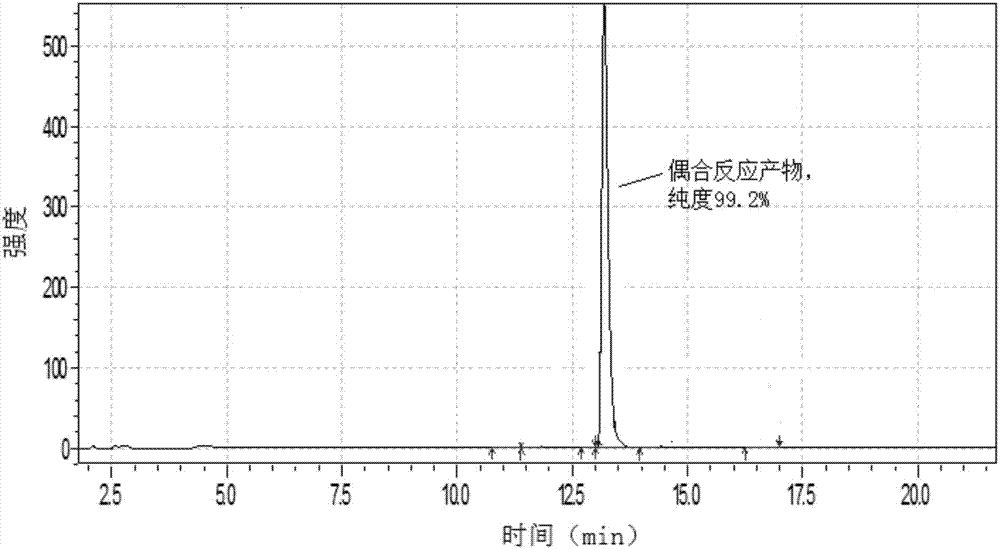

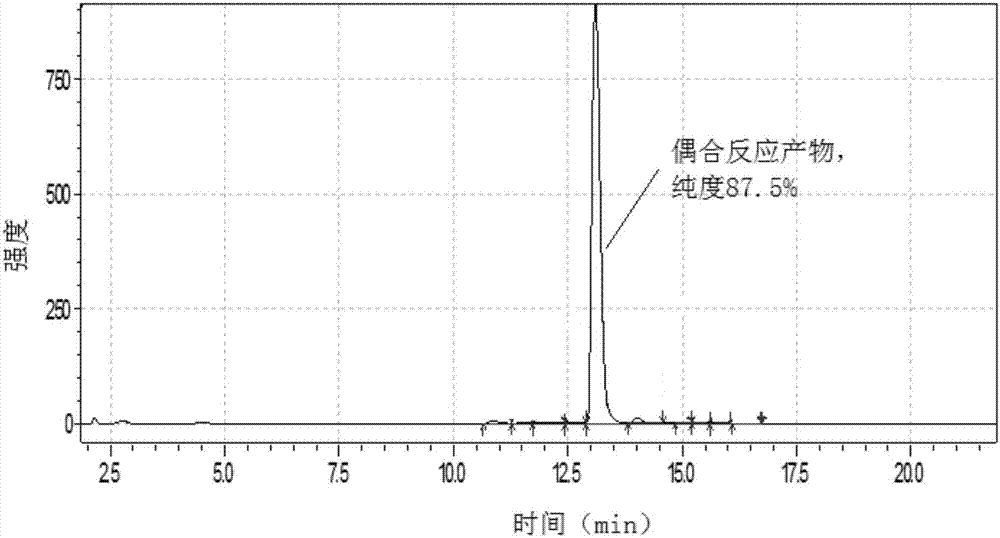

[0080] Stir the feed liquid in the coupling kettle, cool down to 25°C, add 1.2g of C10 alcohol, add 720g of diazonium hydrochloride solution of o-nitroaniline to the kettle dropwise from the diazo solution dropping tank, and control the reaction temperature at 25°C during the dropping process. ~30°C, add dropwise for 5 hours, stop the reaction after the sampling test is qualified; after the reaction, add liquid caustic soda to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com