A method and system for low-temperature liquid-phase hydrotreating of Fischer-Tropsch synthetic oil

A technology for Fischer-Tropsch synthetic oil and liquid phase hydrogenation, which is applied in refining to remove heteroatoms, etc., can solve the problems of inability to ensure the smooth operation of the device, the quality of refined oil, difficult control of the reaction temperature, and unstable operation of the device, and saves the device. Construction and operation costs, reduced energy consumption, and the effect of thorough response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example is used to illustrate the method and system for low-temperature liquid-phase hydrotreating of Fischer-Tropsch synthetic oil provided by the present invention.

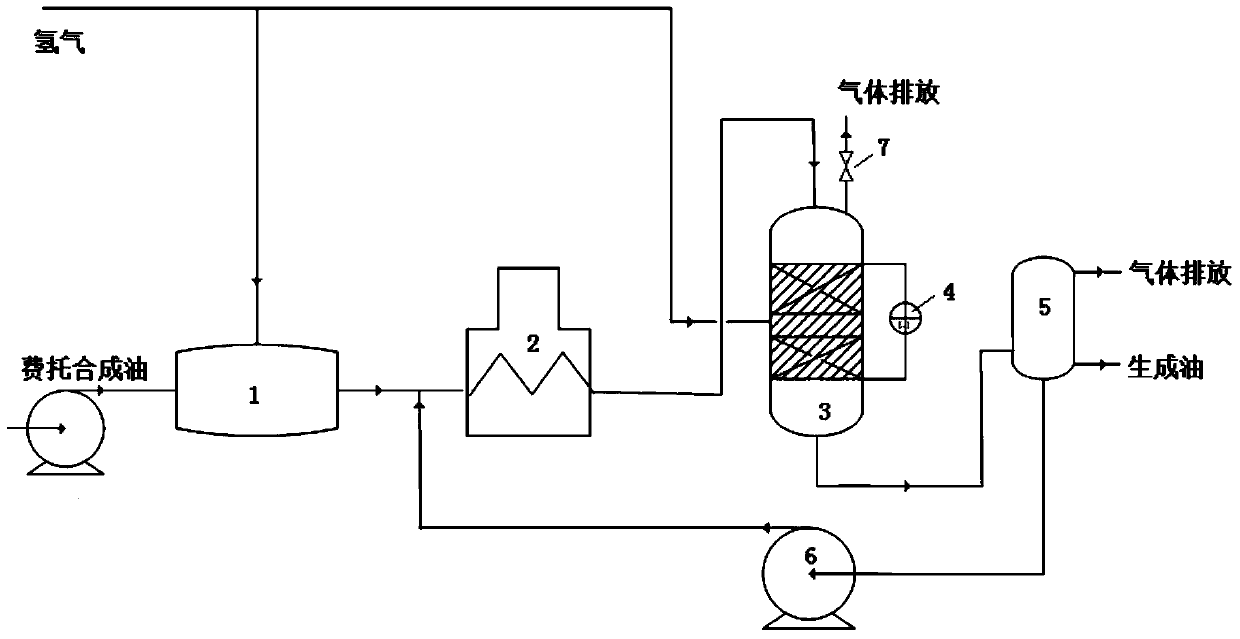

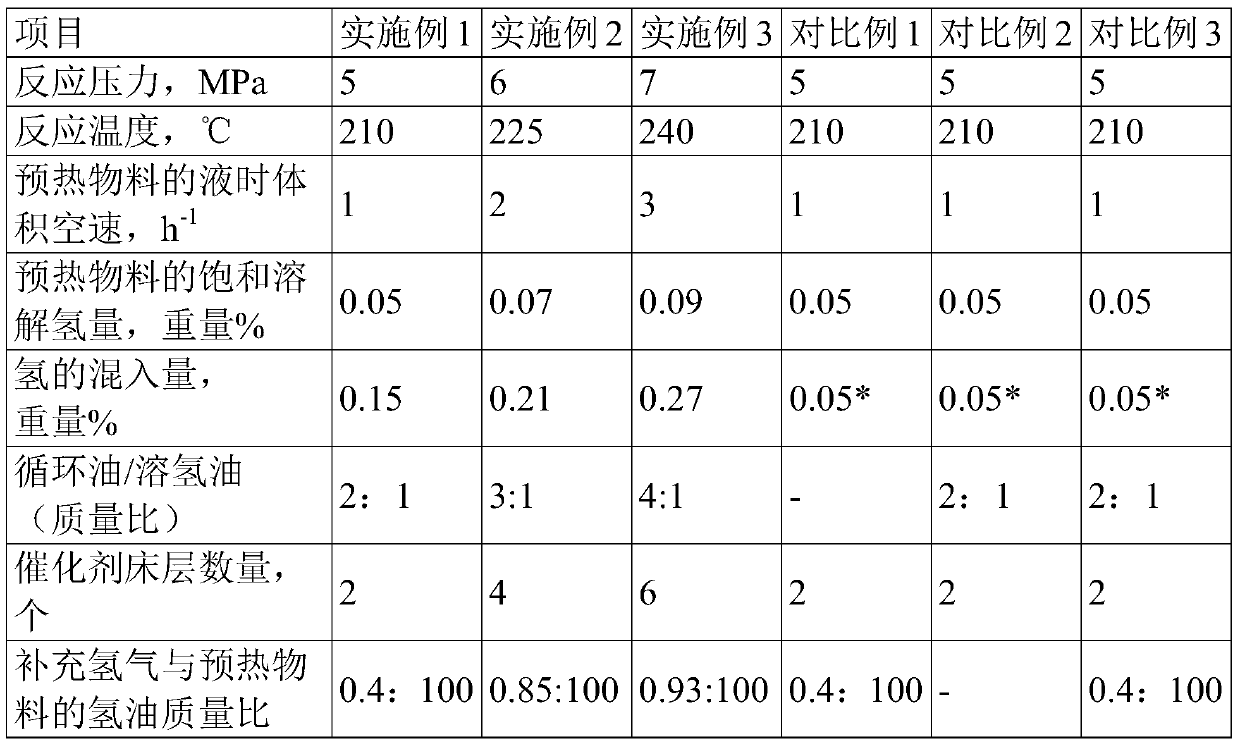

[0038] according to figure 1 According to the flow chart shown and the operating conditions listed in Table 3, the Fischer-Tropsch synthetic oil (see Table 1 for properties) is hydrofined. The process is as follows:

[0039] Mix Fischer-Tropsch synthetic oil and hydrogen in a hydrogen-oil mixer to form a gas-liquid two-phase mixture of hydrogen bubbles and hydrogen-dissolved oil, then mix it with circulating oil and send it to a preheater for preheating to obtain preheated materials;

[0040] The preheated material is sent to a fixed-bed reactor with a liquid level control valve, and passes through the catalyst bed from top to bottom. The liquid-phase hydrogenation catalyst in the catalyst bed is Ni-Mo series model FF-26 (specifically The physical properties are shown in Table 2); In the catalyst ...

Embodiment 2

[0044] According to the method of Example 1, the operating conditions listed in Table 3 were used to carry out the hydrofinishing reaction.

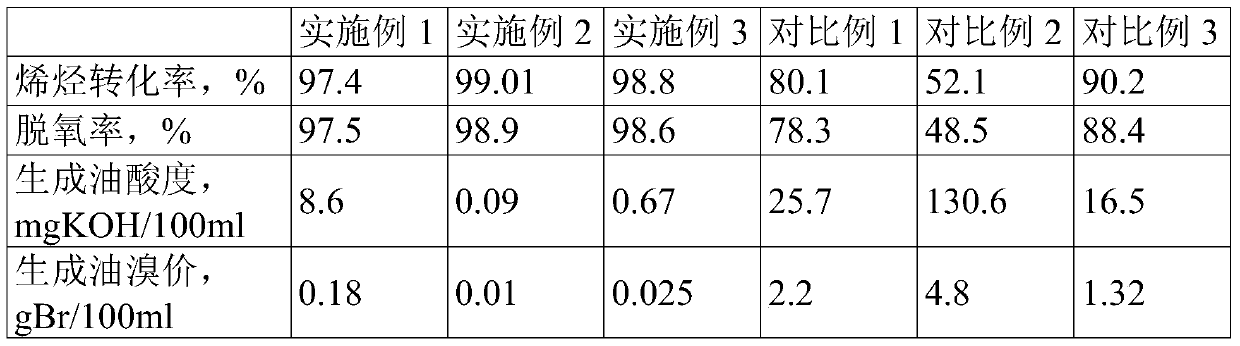

[0045] The reaction results after the hydrofining reaction was carried out for 200 hours are shown in Table 4.

Embodiment 3

[0047] According to the method of Example 1, the operating conditions listed in Table 3 were used to carry out the hydrofinishing reaction.

[0048] The reaction results after the hydrofining reaction was carried out for 200 hours are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com