A vertical breakwater with open caisson

An open-hole caisson, vertical technology, applied in breakwaters, caissons, embankments, etc., can solve problems such as increased engineering volume, adverse effects, and increased cost, and achieve the effects of improving overall stability, reducing wave energy, and reducing section size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

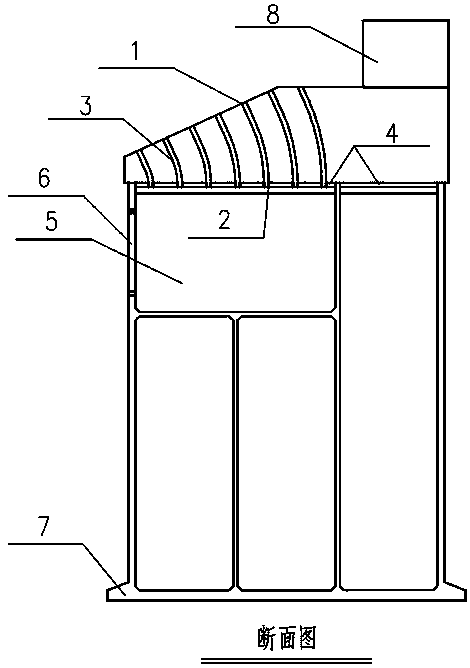

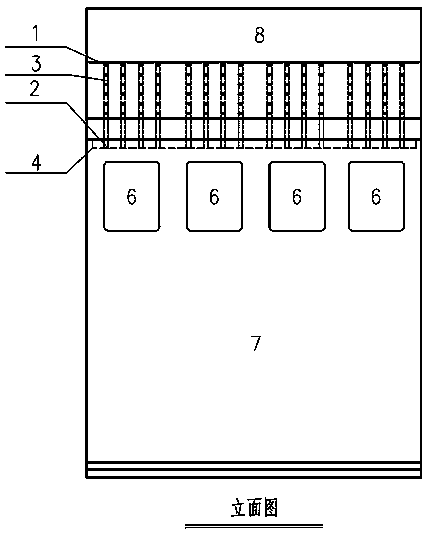

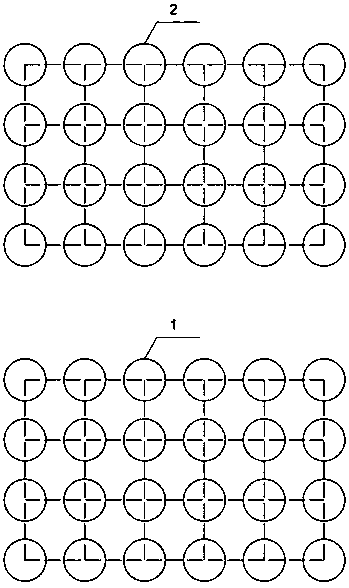

[0014] Such as figure 1 , 2 As shown, the perforated caisson vertical breakwater of the present invention includes a caisson 7 and a parapet 8, wherein a partition wall or a partition is arranged inside the caisson 7 to form several compartments, and the outer wall of the upper part of the caisson 7 is provided with a caisson opening 6 , the subdivision behind the opening 6 of the caisson is used as the wave dissipating chamber 5, and other subdivisions of the caisson 7 except the dissipating chamber 5 are filled with sand; 8 is arranged on the top of the top plate 4, and the wave-facing side of the breast wall 8 is provided with an inclined surface, and several water outlets 1 are arranged on the inclined surface, and the water outlets 1 communicate with the water inlet 2 opened on the top plate 4 through the pipe 3. The bottom of above-mentioned caisson 7 is foundation bed, bottom protection, and foundation bed, bottom protection are identical with traditional upright emban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com