A vacuum suppressor for water supply without negative pressure

A vacuum suppressor, no negative pressure technology, used in water supply devices, water saving, configuration of water supply pools, etc., can solve problems such as overflow, tap water pollution, seepage of inlet and exhaust holes, etc., to prolong service life and improve sealing effect. , The effect of preventing impact deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

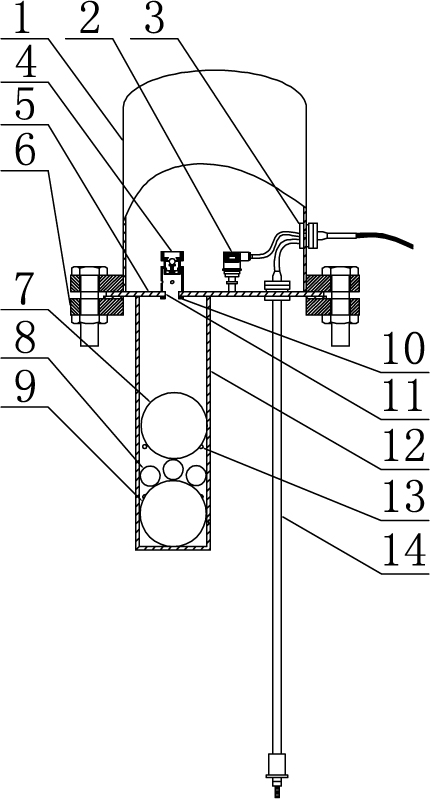

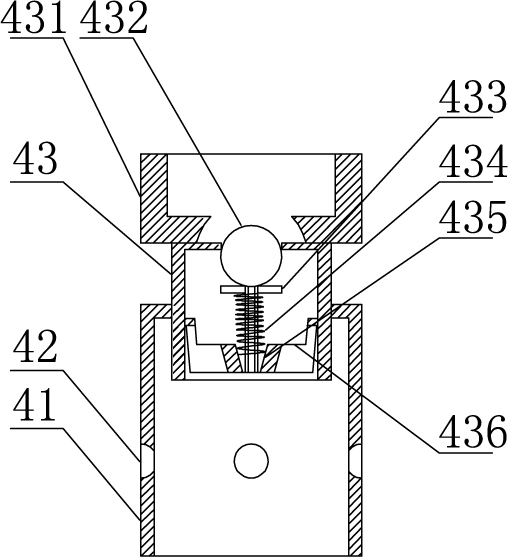

[0018] like figure 1 As shown, the vacuum suppressor for water supply without negative pressure of the present invention includes a protective cover 1 installed at the exhaust port 6 of the steady flow tank and a float bucket 12, and the float bucket is fixed on the stabilizer through the upper cover 5 of the float bucket. The exhaust port of the flow tank is also provided with a pressure transmitter 2 for monitoring the pressure in the stable flow tank and a liquid level sensor 14 for monitoring the liquid level in the stable flow tank on the top cover of the float bucket, and a data line is arranged on the protective cover. The hole, the data line of the pressure transmitter and the data line of the liquid level sensor are led to the outside of the protective cover through the gland 3. The body of the float bucket is located in the steady flow tank, the wall of the float bucket is provided with a communication hole 13 for the water in the steady flow tank to enter the float ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com