The installation structure and construction method of the temporary waterproof device when the shield reaches the non-main structure

A technology of main structure and waterproof device, applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve problems such as affecting construction efficiency, prolonging construction progress and construction period, prolonging process conversion time, etc., so as to improve construction efficiency and shorten the The construction progress and construction period, the effect of saving process conversion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

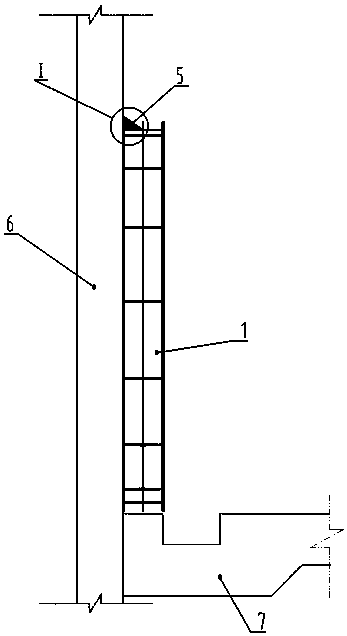

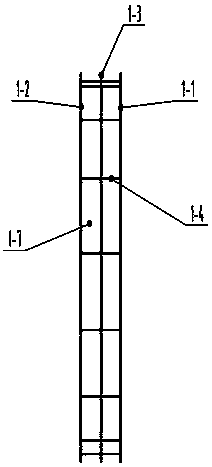

[0037] see Figure 1-2 , in the figure, the shield of the present invention reaches the temporary waterproof device installation structure without a main structure, including a connecting steel ring 1, double rows of steel bars 2, steel mesh 3, and concrete 5.

[0038] Wherein, the connecting steel ring is located on the ground connection wall 6 and matches with the set hole. The double rows of steel bars are arranged on the outside of the connecting steel ring in a circular direction, and are implanted in the ground connection wall, and the implanted double rows of steel bars and the connecting steel ring are coaxially arranged. The outer protruding end connecting the steel ring and the double row of steel bars is welded and fixed. The steel mesh is bound on the external extension of the double row of steel bars, and C30 concrete is molded to seal the gap between the steel ring and the ground wall. The row spacing of the double-row steel bars is 30cm, the circumferential sp...

Embodiment 2

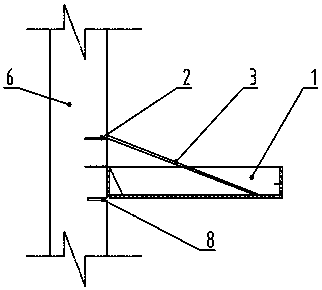

[0051] see figure 2 , the structure of this embodiment is similar to that of Embodiment 1, and the same parts of the structure will not be repeated here. The difference is that this embodiment also includes a full-circle cutout hole 8 inside the door that is located on the inner side of the connecting steel ring, and the cutout hole The depth is consistent with the depth of the planted reinforcement, which is used to reduce the disturbance of the connection position of the steel ring when the shield tunneling tool cuts the door.

[0052] The specific construction steps 1 to 4 of this embodiment are described in Embodiment 1, and will not be repeated here. The difference is that it also includes step 5, drilling the entire ring inside the door:

[0053]The full-ring resection of the portal is carried out on the inner side of the connecting steel ring, and the depth of the resection is consistent with the depth of the reinforcement, so as to reduce the disturbance of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com