Sound insulation and noise reduction modular wallboard

A modular, sound-insulating panel technology, which is applied in sound insulation, clothing, floors, etc., can solve the problem of poor noise reduction effect of modular wall panels, and achieve the effect of improving sound insulation and noise reduction effects and reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

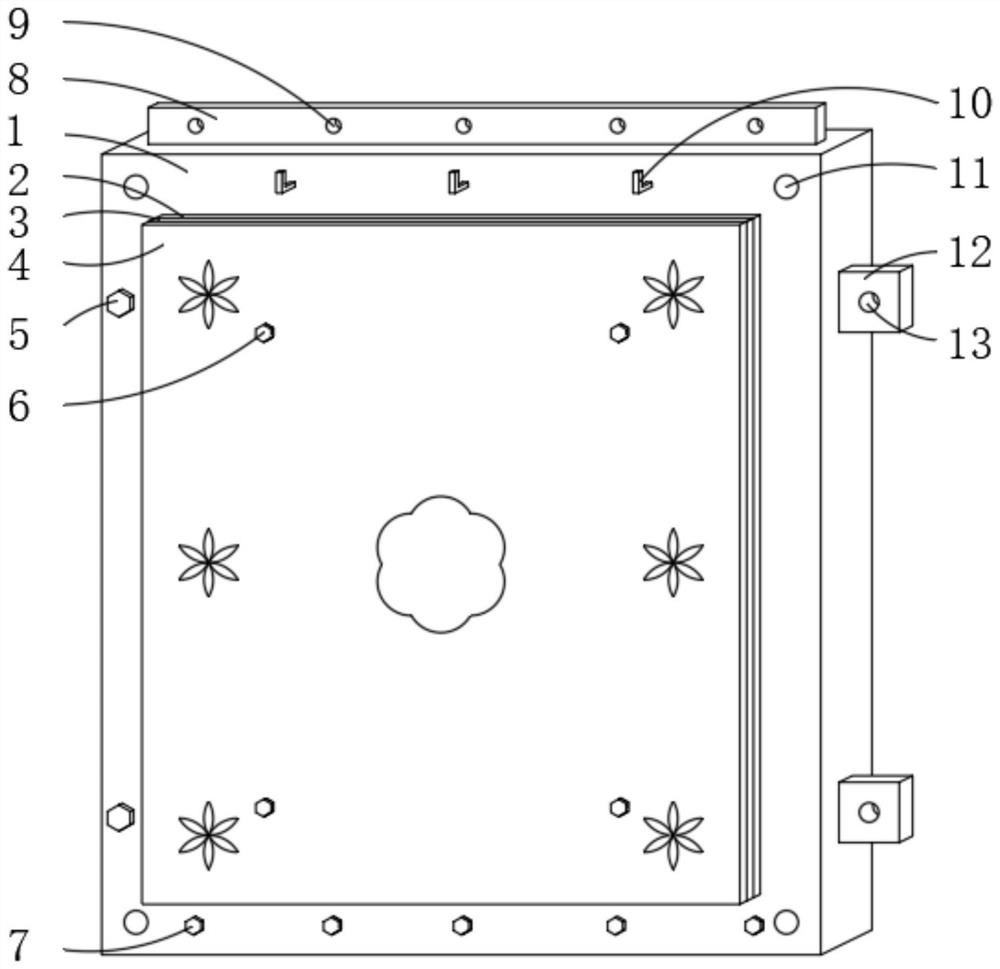

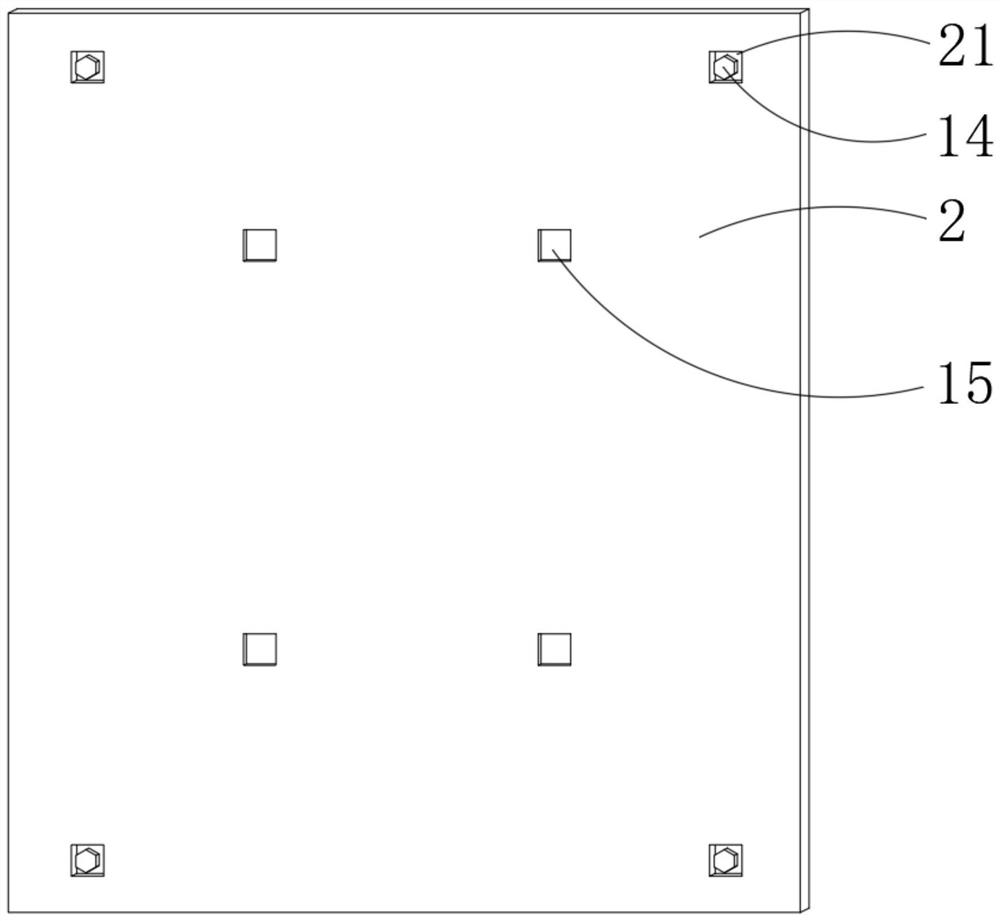

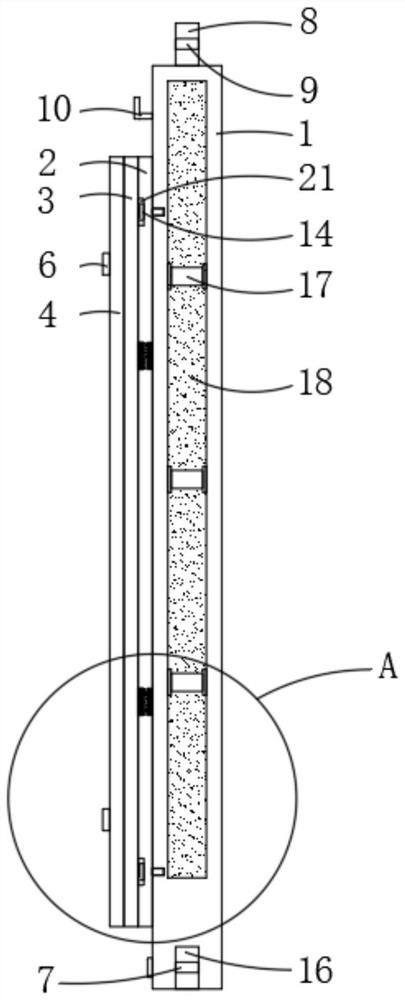

[0038] Embodiment one: if Figure 1-4The present embodiment shown is a method of using a sound-insulating and noise-reducing modular wall panel: the main sound-insulating panel 2 is installed on the base plate 1 by locking bolts 14, and then the use of the base plate 1 is expanded through the up-down connection structure and the left-right connection structure area, and then install the assembled substrate 1 on the wall, and then insert the auxiliary magnet 19 on the auxiliary sound insulation board 3 into the auxiliary groove 15, so that the effect of installing the auxiliary sound insulation board 3 can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com