Rail pressure control method under rail pressure sensor failure mode

A rail pressure sensor, failure mode technology, applied in electrical control, engine control, fuel injection control and other directions, can solve the problems of inability to achieve flexible control, emission and power performance deterioration, and achieve the effect of improving power performance and high-precision adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific drawings and embodiments.

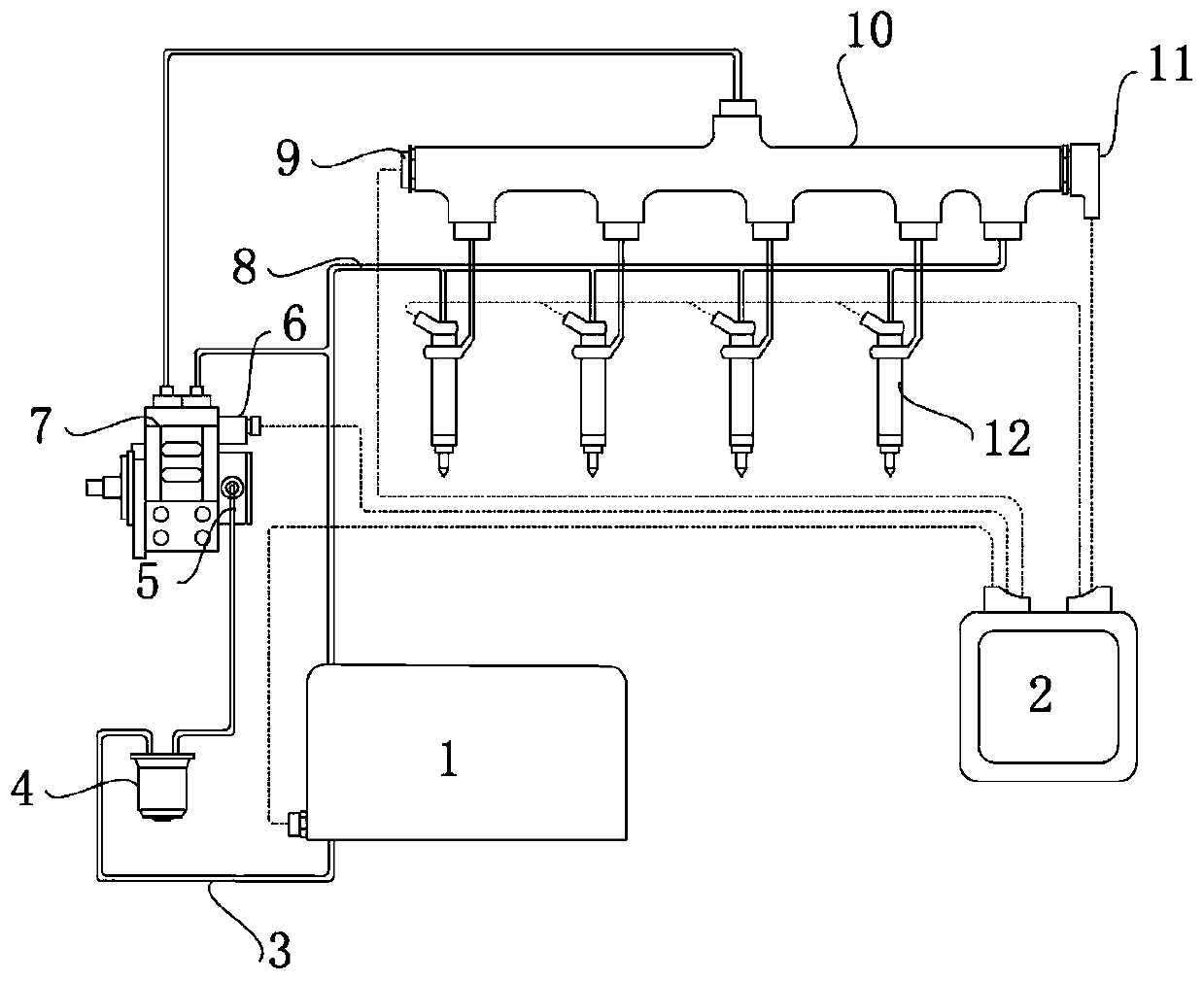

[0037] figure 1 A structural diagram of a fuel system implementing the present invention is shown. The fuel delivery pump 5 delivers fuel from the fuel tank 1 to the high-pressure pump 7, and the flow regulating valve 6 controls the fuel flow into the high-pressure pump 7. The fuel is pressurized by the high-pressure pump 7 and stored in the high-pressure rail pipe 10, and the fuel injector 12 passes through the high-pressure fuel pipe. Connect with the high pressure rail pipe 10. The pressure regulating valve 11 reduces the pressure in the high-pressure rail pipe 10 by releasing high-pressure fuel into the oil return pipe 8 , and the return oil in the oil return pipe 8 finally returns to the fuel tank 1 .

[0038] In addition, the system also includes a control unit 2, which controls the flow regulating valve 6, the pressure regulating valve 11 and the fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com