Hydraulic power antiresonance isolation device

An anti-resonance, hydraulic technology, applied in the direction of shock absorber, shock absorber-spring combination, spring, etc., can solve the problems of large stiffness value, strong nonlinearity of the main spring, difficult to determine, etc., and achieve small stiffness and deformation range Large, small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

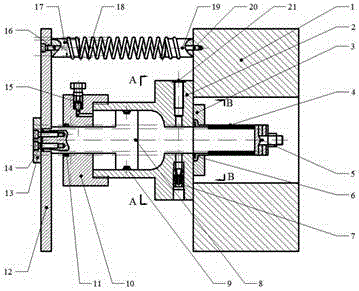

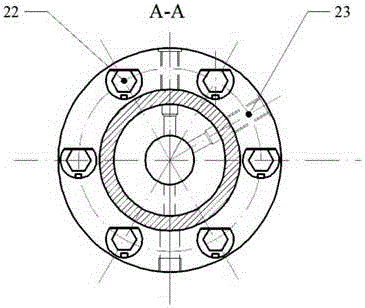

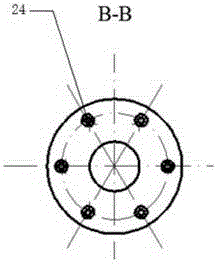

[0029] Please refer to Figure 1-4 , a hydraulic power anti-resonance vibration isolation device, including a hydraulic cylinder, a welded bellows 4, a main mass 12, a base 1, a coil spring 18 and a suspension mass 5, a welded bellows 4, a main mass 12, a base 1, and a suspension mass 5 is arranged coaxially with the hydraulic cylinder; one end of the welded bellows 4 is sealed with a suspension mass 5, and the other end of the welded bellows 4 is connected with the hydraulic cylinder; the main mass 12 is connected with the hydraulic cylinder to drive the hydraulic oil in the hydraulic cylinder Linear reciprocating motion; the base 1 is used to support the hydraulic cylinder; the main mass 12 and the base 1 are connected with a coil spring 18, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com