Single-input and double-output gear box and multi-point meshing gear driving system of ultra-large-sized mill

A single-input, double-output, gearbox technology, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of high cost of motor and control system, high cost of spare parts and maintenance, and extremely high environmental requirements. Achieve the effect of improving the load equalization effect, easy installation and maintenance, and simple transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific embodiments.

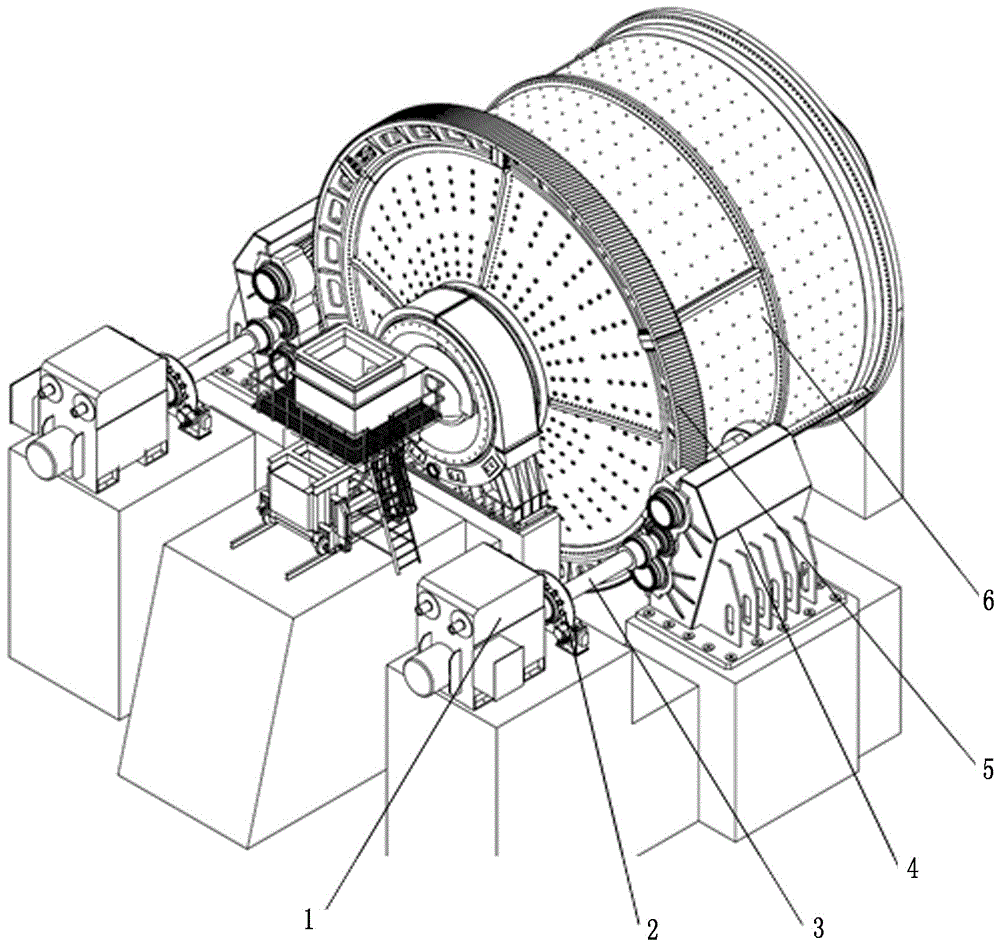

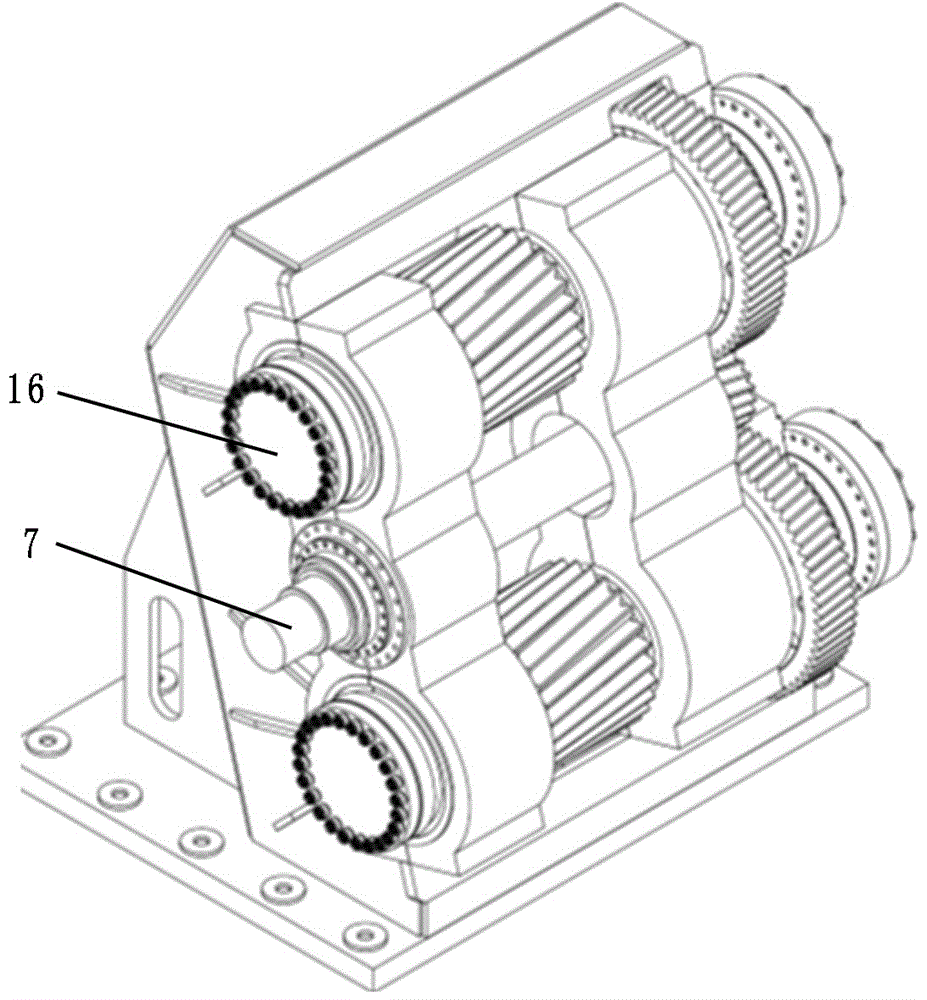

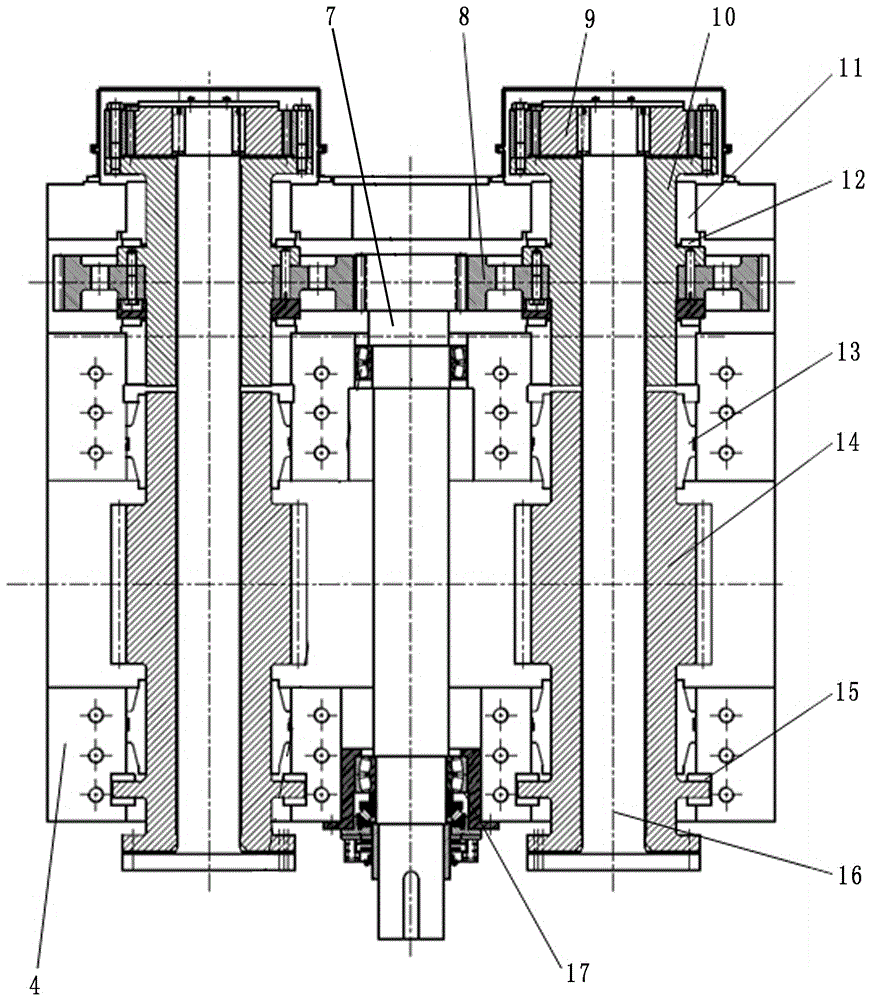

[0019] like Figure 1-3 As shown, a super-large mill multi-point meshing gear drive system, the super-large mill includes a mill body 6 and an open ring gear 5, the open ring gear 5 is sleeved on one end of the mill body 6 and passed through The flange is fixedly connected with the mill body 6, and the gear drive system adopts two single-input and double-output gearboxes, and the two gearboxes are symmetrically arranged on both sides of the mill body 6; One input shaft 7 and two torsion shafts 16, the torsion shaft 16 is provided with a hollow shaft I10 and a hollow shaft II14, the hollow shaft I10 and the hollow shaft II14 are respectively fixedly connected with the torsion shaft 16, and one end of the input shaft 7 is set There is a first-stage pinion gear, a first-stage large gear 8 is provided in the middle of the hollow shaft Ⅰ10, and two first-stage large g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com