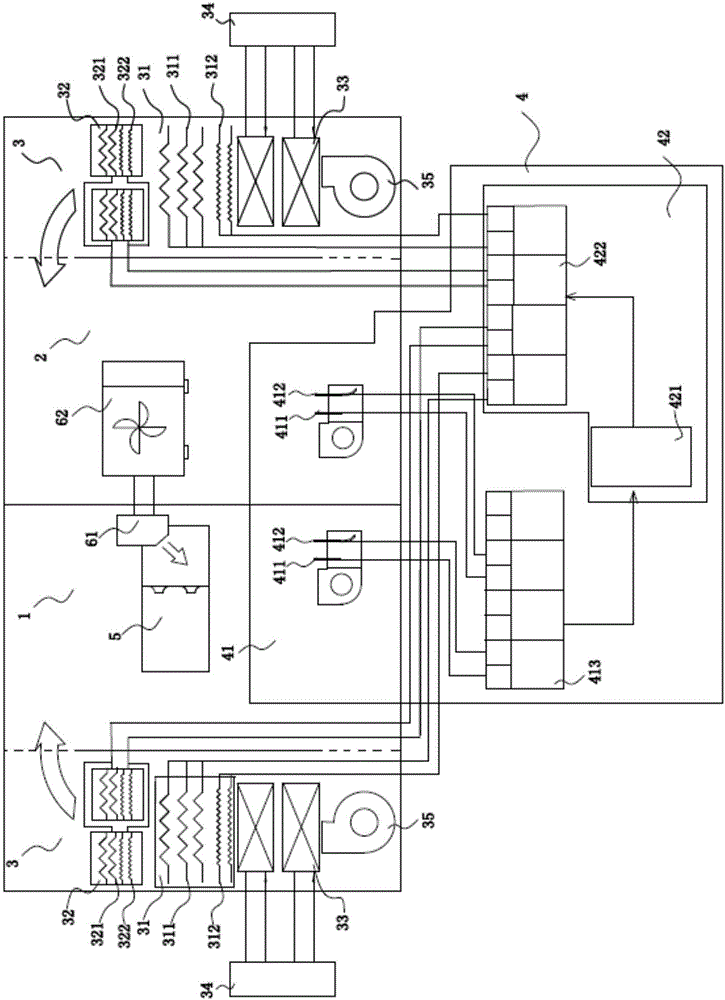

High precision air-conditioning capability test apparatus

A test device and high-precision technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as poor consistency, large changes in air conditioning capacity, long measurement cycles, etc., and achieve accurate and consistent capacity values High, short operating cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

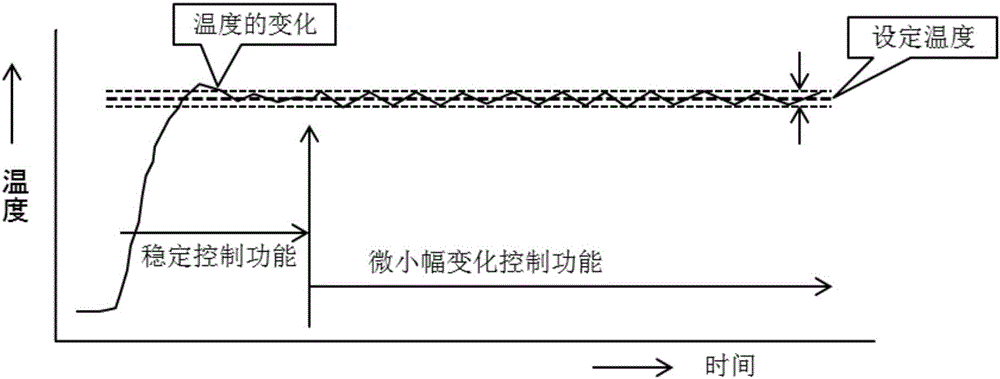

[0058] By adopting the second implementation mode, 1) the ambient temperature and humidity are controlled within the range of ±0.01K, and the periodic fluctuation is centered on the target value; 2) the tested air conditioner capacity value is accurate and consistent; 3) The operation period is short, which reduces the laboratory operation cost. Regardless of whether the first implementation or the second implementation is adopted, after entering the micro-amplitude control, that is, when the change curves of the measured values of the dry bulb temperature and wet bulb temperature fluctuate periodically around the set value, it is necessary to collect Proficiency testing uses data to complete proficiency testing.

[0059] The specific working process of the high-precision air-conditioning capability test device is illustrated below in conjunction with the first embodiment:

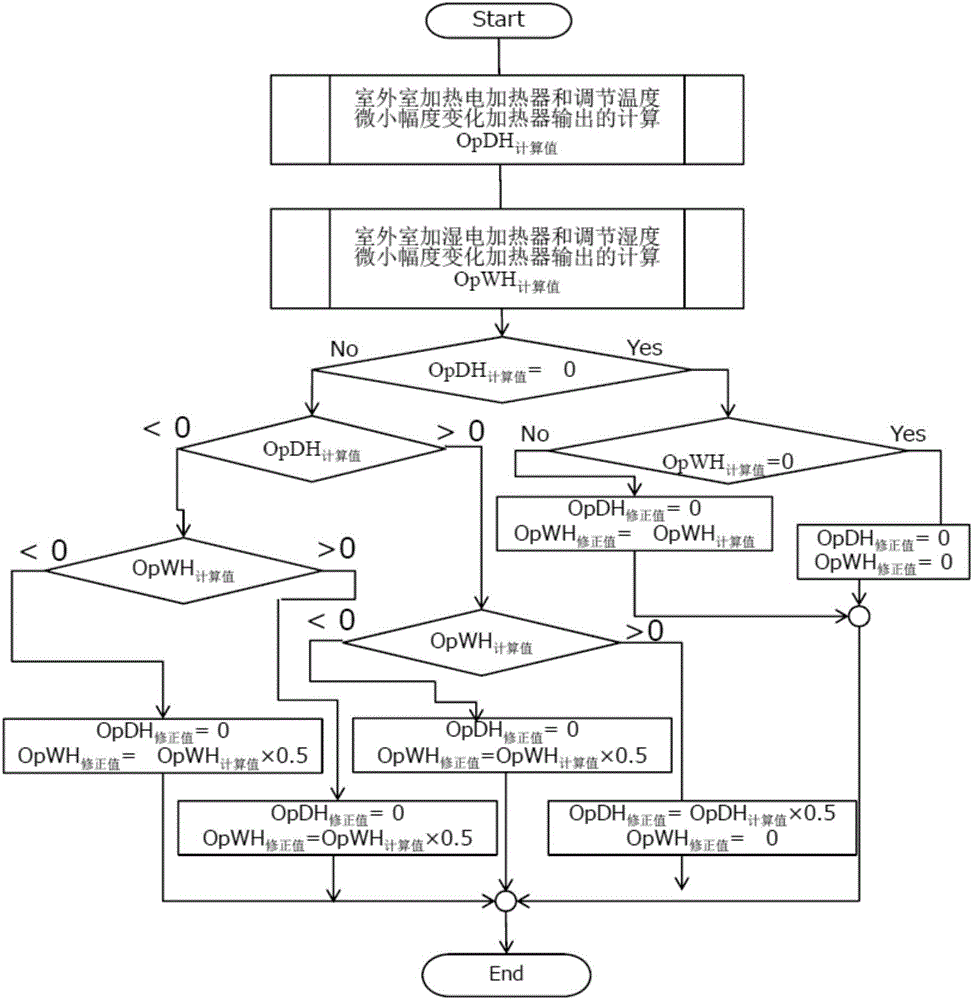

[0060] see Figure 5 , the test starts, and the high-precision air-conditioning capability test dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com