High-precision aligned stitching testing machine

A technology of aligning and pressing, testing machine, applied in capacitance measurement, measuring device, measuring electrical variables, etc., can solve the problems of inaccurate alignment of test needle and test point, increase speed and work efficiency, and high probability of test error. , to achieve the effect of convenient application, increased accuracy and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

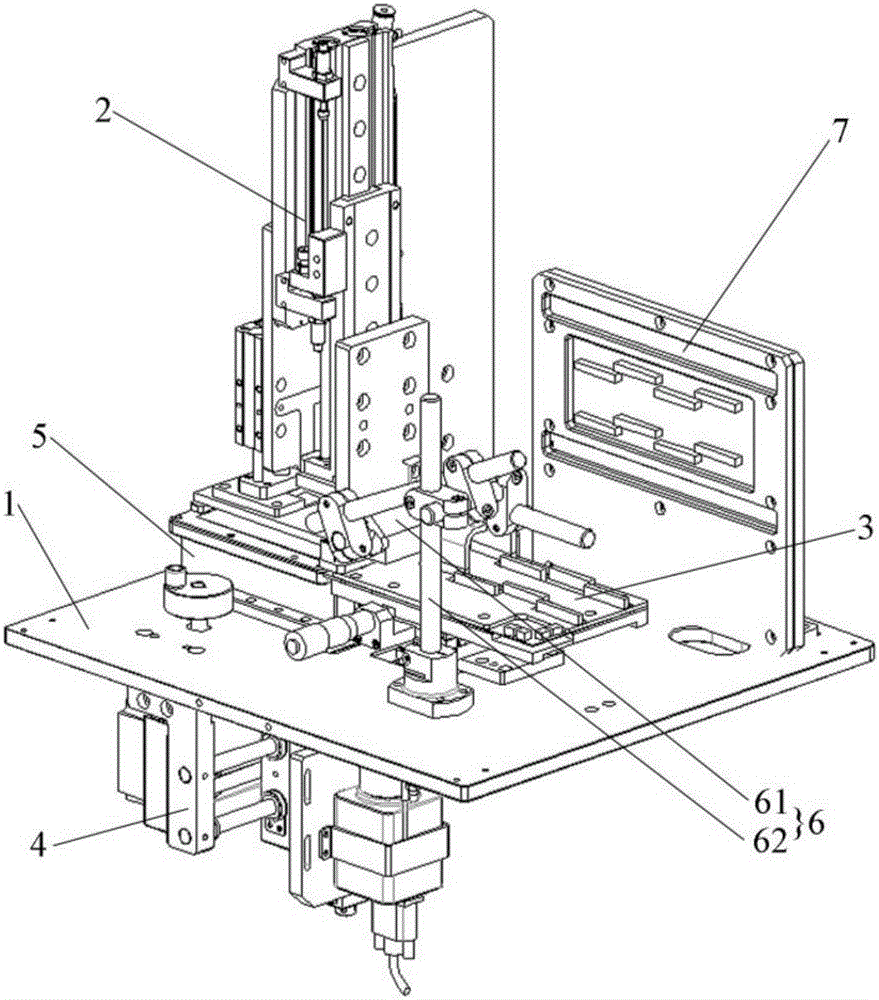

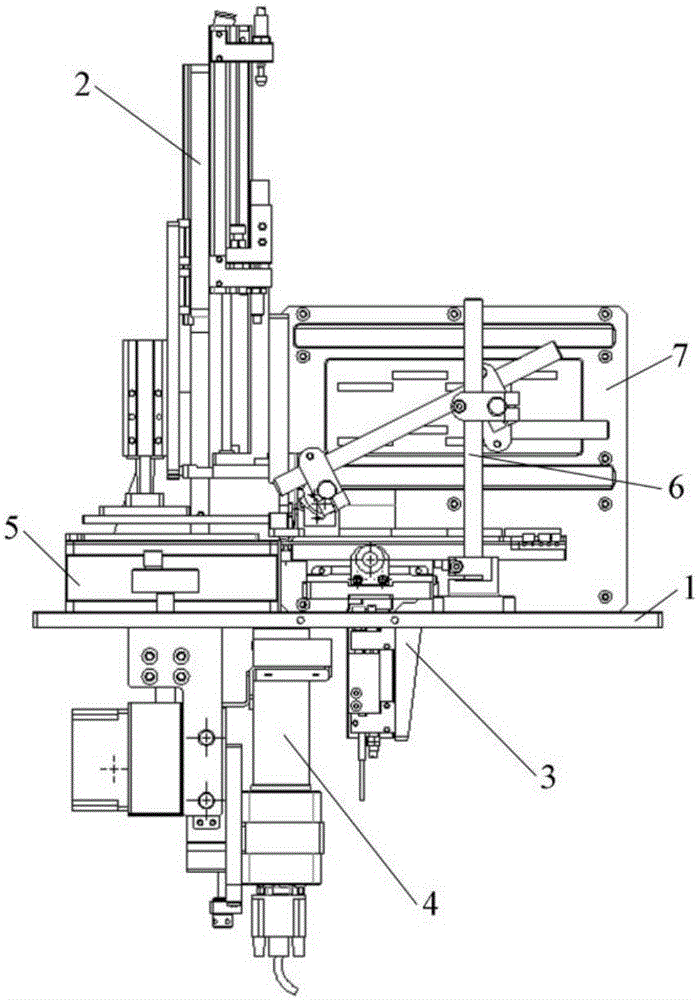

[0027] Such as Figure 1-2 The high-precision alignment press-fit testing machine includes a support plate 1, a pressing unit 2, an FPC board structure unit 3, an alignment camera unit 4, a carrier unit 5, a backlight light source unit 6, and an adapter plate 7. The support A set of openings is provided on the board 1, and the FPC board structural unit 3 is arranged on the supporting board 1 through the opening; a carrier unit 5 is provided on one side of the FPC board structural unit 3, and a A pressing unit 2 is also provided; an alignment camera unit 4 is provided under the support plate 1 . The backlight light source unit 6 and the adapter plate 7 are also arranged on the support plate 1, wherein the backlight light source unit 6 includes a backlight light source 61 and an adjustment frame 62, and the backlight light source 61 is arranged on the adjustment frame 62. Board 7 is also connected with the electric control box assembly.

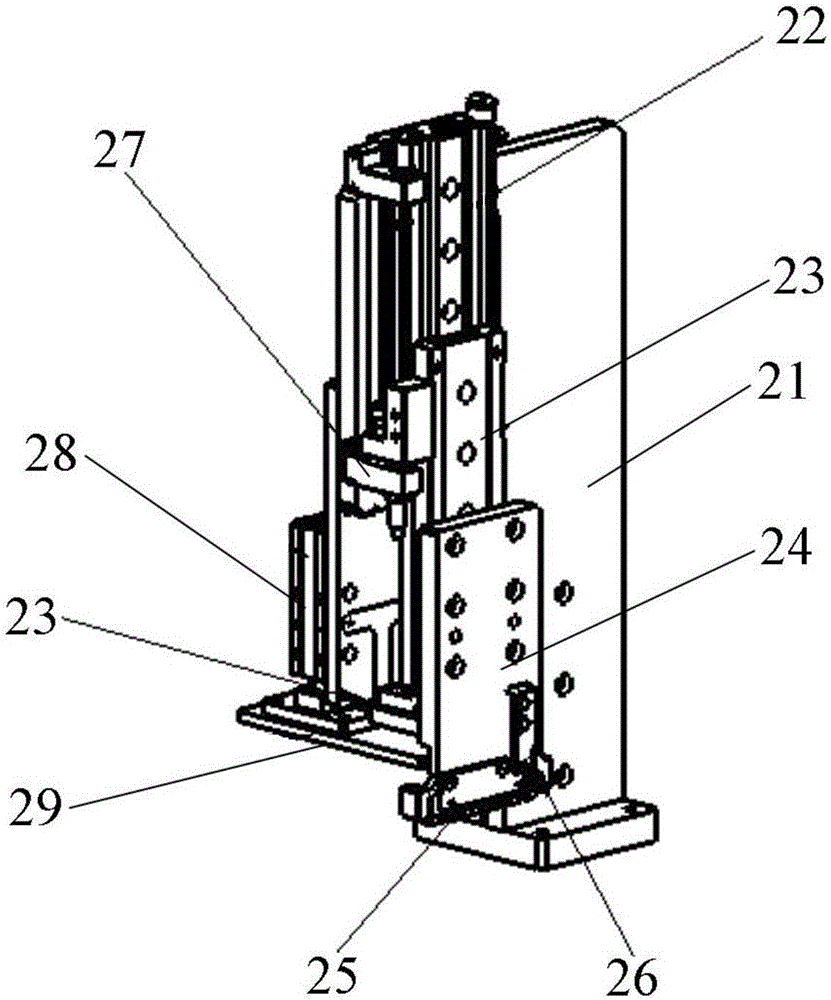

[0028] Again, if image 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com