New type spraying robot positive pressure explosion-proof system

A spraying robot, positive pressure explosion-proof technology, applied in control/adjustment systems, instruments, non-electric variable control, etc., can solve the problems of controlling the sealed cavity, unable to control the automatic adjustment of the positive pressure of the spraying robot shell, etc., to achieve closed-loop pressure flow Control and reduce the effect of human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

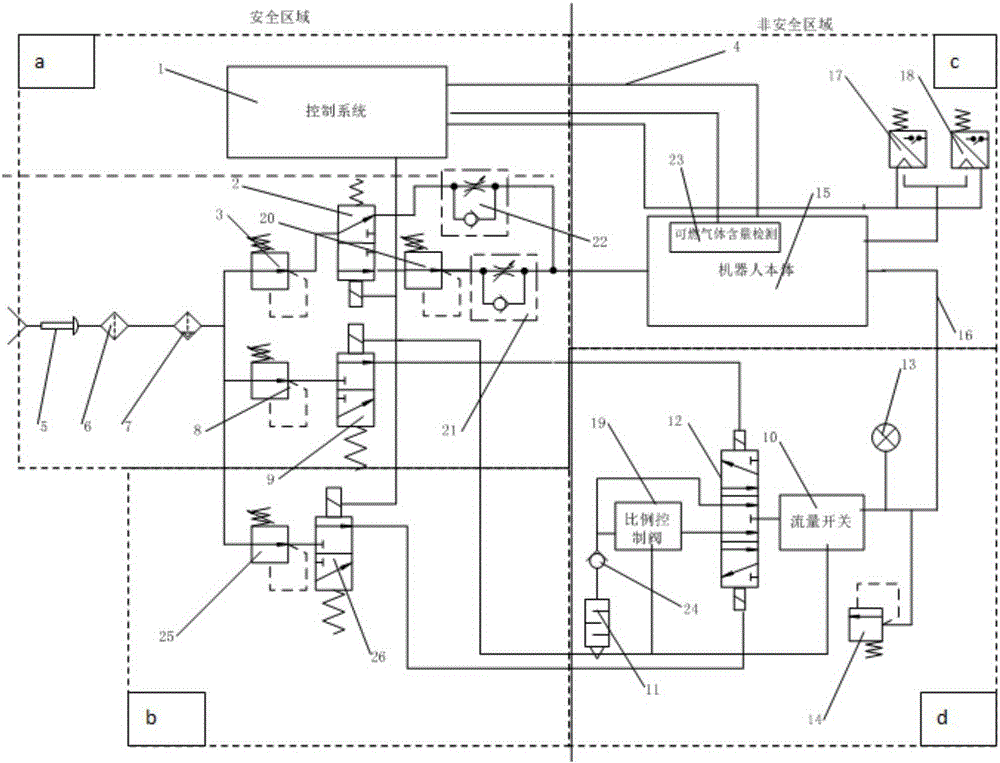

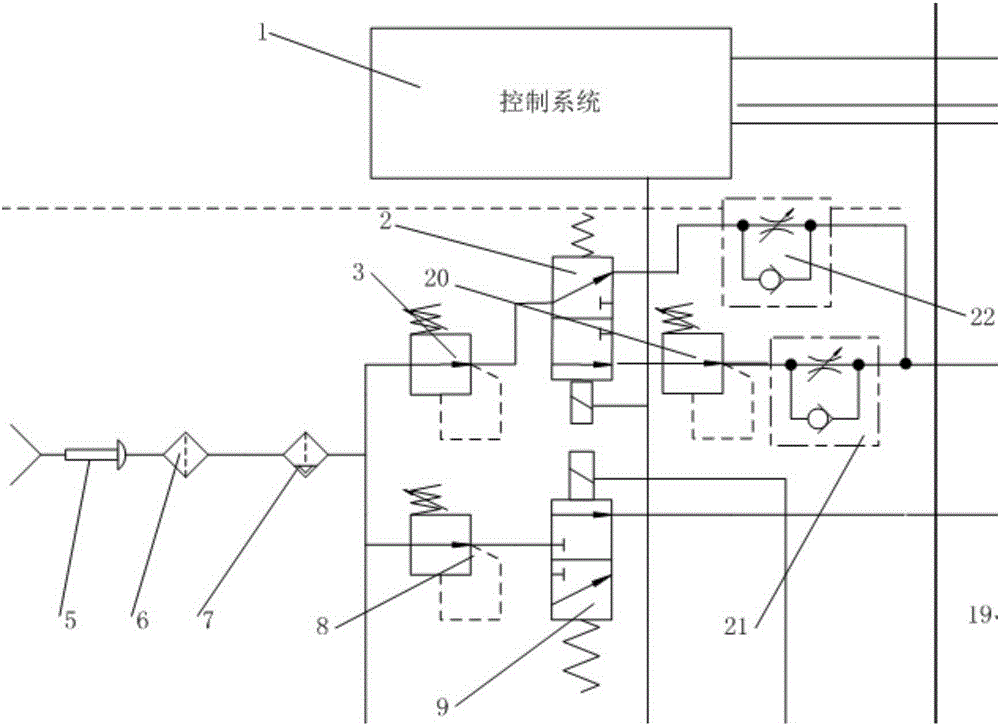

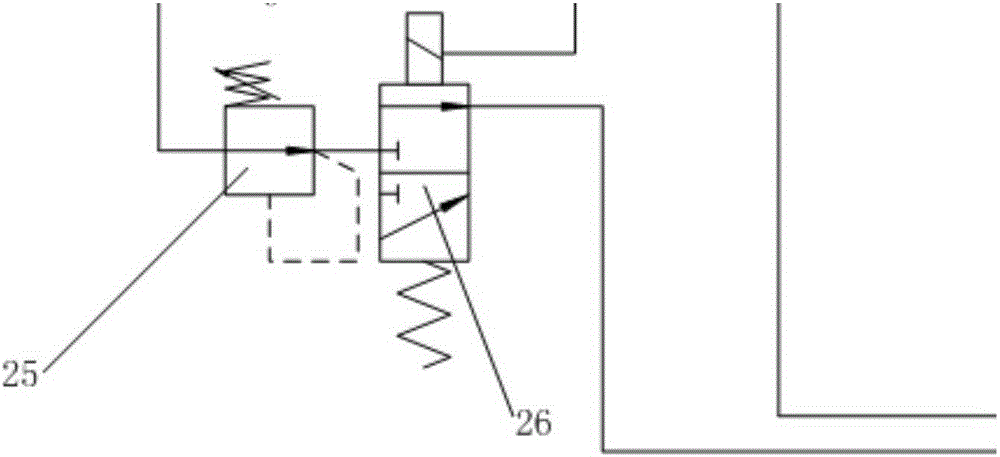

[0026] Such as figure 1 , 2 , 3, 4, and 5, a new type of spraying robot positive pressure explosion-proof system, including a control system 1, a robot body 15, a combustible gas content detection device 23, a first pressure switch 17, a second pressure switch 18, the first two Three-position reversing valve 2, second two-position three-way reversing valve 9, third two-position three-way reversing valve 26, proportional control valve 19 and flow switch 10;

[0027] The control system 1 is electrically connected to the robot body 15, the combustible gas content detection device 23, the first pressure switch 17, the second pressure switch 18, the first two-position three-way reversing valve 2, and the second two-position valve through the control cable 4. Three-way reversing valve 9, third two-position three-way reversing valve 26, proportional control valve 19 and flow switch 10;

[0028] The new spraying robot positive pressure explosion-proof system also includes a manual v...

Embodiment 2

[0035] The pipeline connecting the robot body 15 with the first pressure switch 17 and the second pressure switch 18 is also provided with a third pressure switch, and the first pressure switch 17, the second pressure switch 18 and the third pressure switch all adopt this Safety type pressure switch, all the other structures are identical with embodiment 1;

[0036] Its function is because the pressure switch adopts the intrinsically safe type, and the pressure switch can be directly powered on before the exhaust gas is discharged. In this mode, the pressure switch is powered on, the reversing valve is in the long-pass state, the manual valve is opened, and the gas passes through the pressure reducing valve. , The two-way reversing valve and the speed control valve enter the robot body to supply air to the body. The speed control valve is used to adjust the intake speed. When the pressure value of the pressure switch reaches the set positive pressure value, the control system a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com