Installation sleeve device for single pile type multi-cable protection pipe

A technology for installing sleeves and cable guards, which is applied to cable laying equipment and other directions, can solve the problems of low installation efficiency and accuracy, and high costs, so as to improve construction efficiency and installation accuracy, reduce construction costs, and save construction periods and oilfield development costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

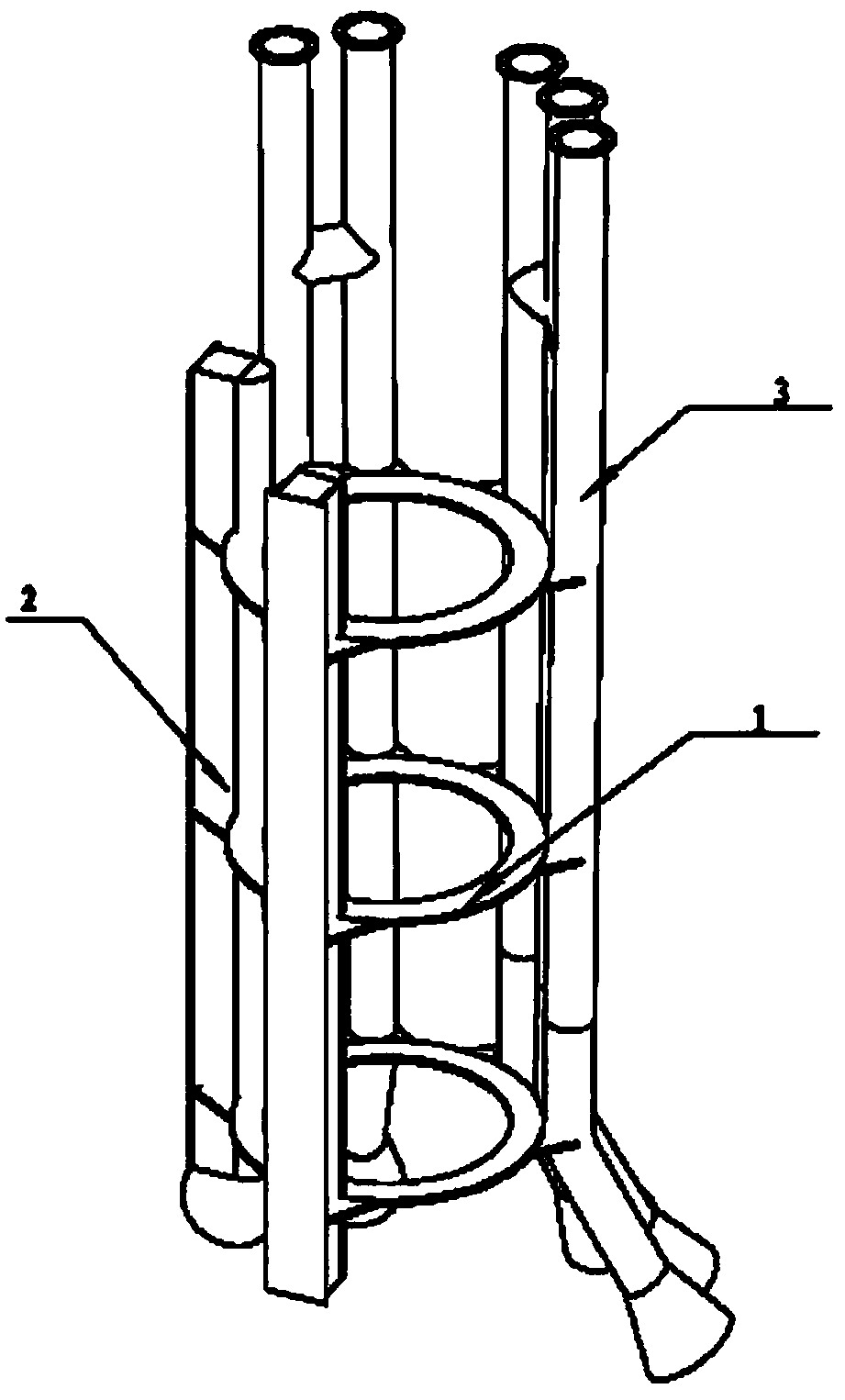

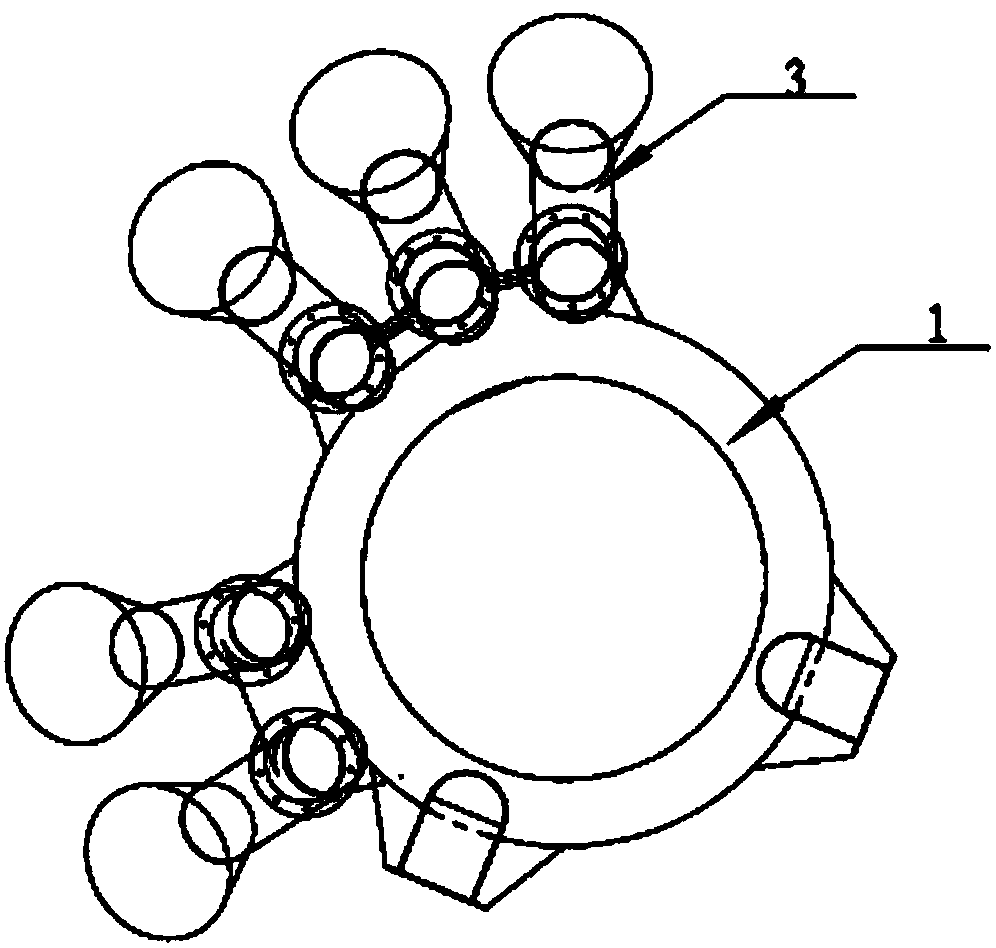

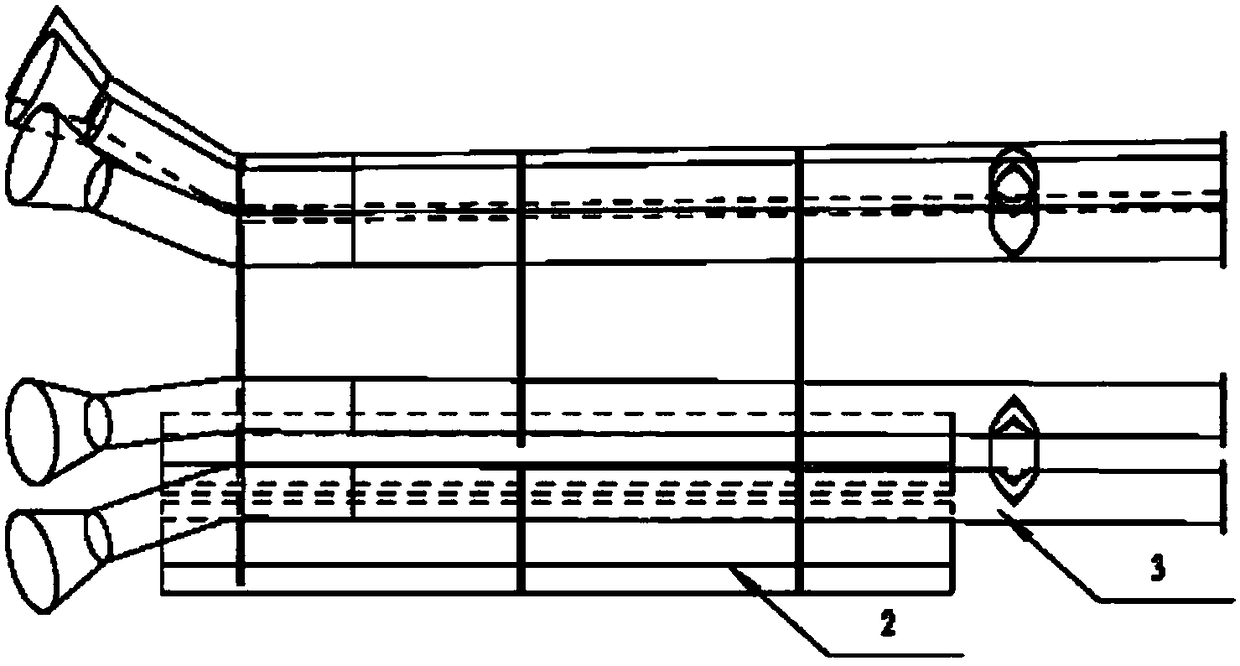

[0024] like figure 1 — image 3 As shown, the present invention includes: a sleeve connected to one or more cable protection tubes 3, and a riser connected to the sleeve by welding; wherein, the connection between the sleeve and multiple cable protection tubes 3 is on land The overall preset is completed; the sleeve ring 1 is arranged at a certain distance on the sleeve, and the support structure 2 is arranged on the side opposite to the standpipe by welding. The function of the support structure 2 is to make the whole structure form a complete closed loop.

[0025] The distance between the above-mentioned sleeve rings 1 on the sleeve is 3 to 5 meters. If the water depth is relatively shallow, the distance between the sleeve rings 1 can be adjusted flexibly. The diameter of the sleeve rings 1 is from bottom to bottom (after installation The direction close to the seabed is the downward direction) and the upward direction (the direction of the sea surface is the upward direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com