Electric vehicle pre-charging control method and system

A technology for electric vehicles and control methods, applied in electric vehicles, battery circuit devices, current collectors, etc., can solve problems such as low pre-charging efficiency of electric vehicles, and achieve the effect of improving pre-charging efficiency, avoiding waste, and improving driving experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

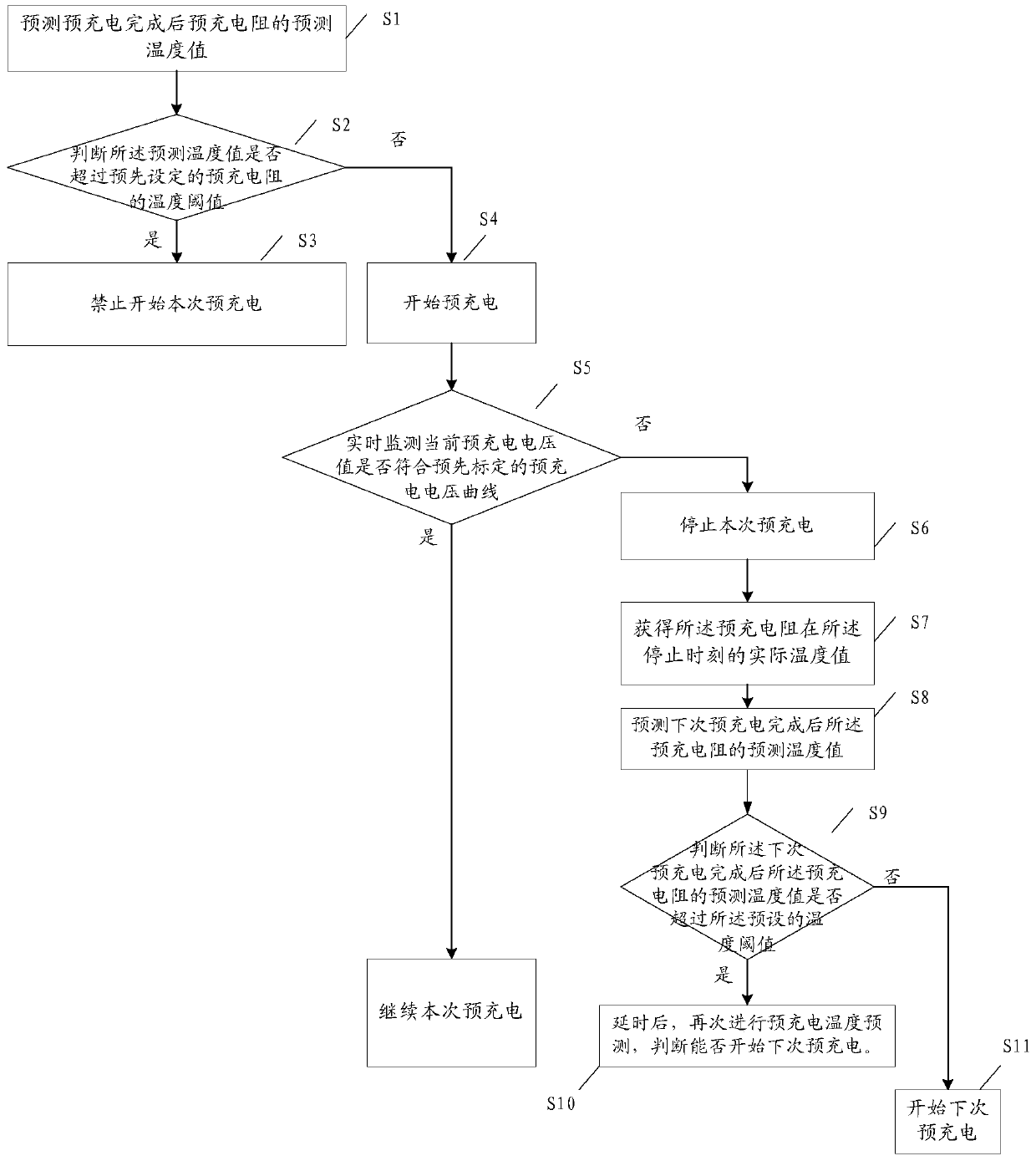

[0062] figure 1 Shown is a kind of electric vehicle precharging control method of embodiment 1 of the present invention, and this method comprises the following steps:

[0063] S1. Predicting the predicted temperature value of the pre-charging resistor after the pre-charging is completed. Before the pre-charging starts, predicting the predicted temperature value of the pre-charging resistor in the pre-charging circuit of the electric vehicle after the pre-charging is completed may specifically include the following steps:

[0064] Firstly, the difference between the voltage of the battery system of the electric vehicle and the voltage of the load circuit is calculated. For example, assuming that the voltage of the battery system of the electric vehicle is V1, and the voltage of the load circuit of the electric vehicle is V2, then the difference V0 is V0=|V1-V2|.

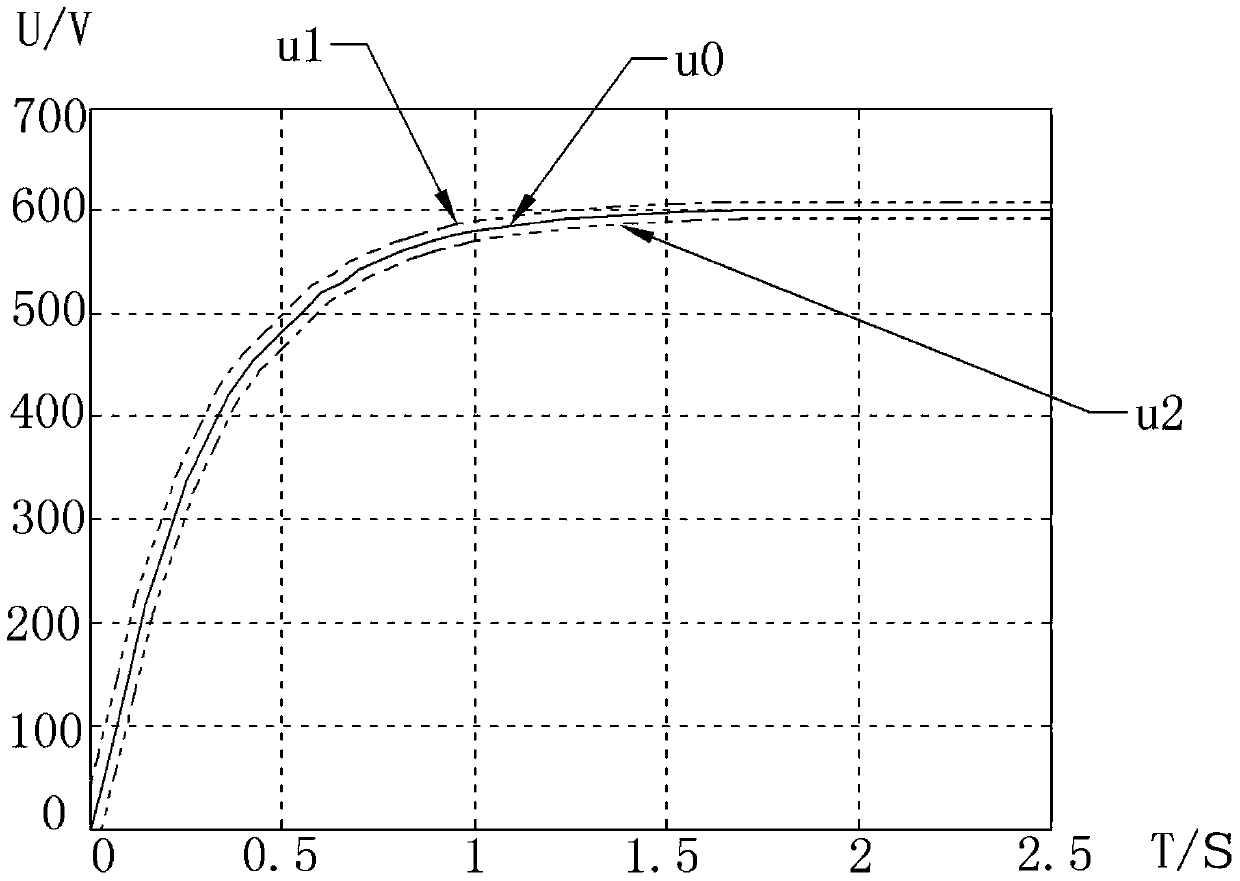

[0065] Secondly, the predicted temperature increase value of the pre-charging resistor after the pre-charging is...

Embodiment 2

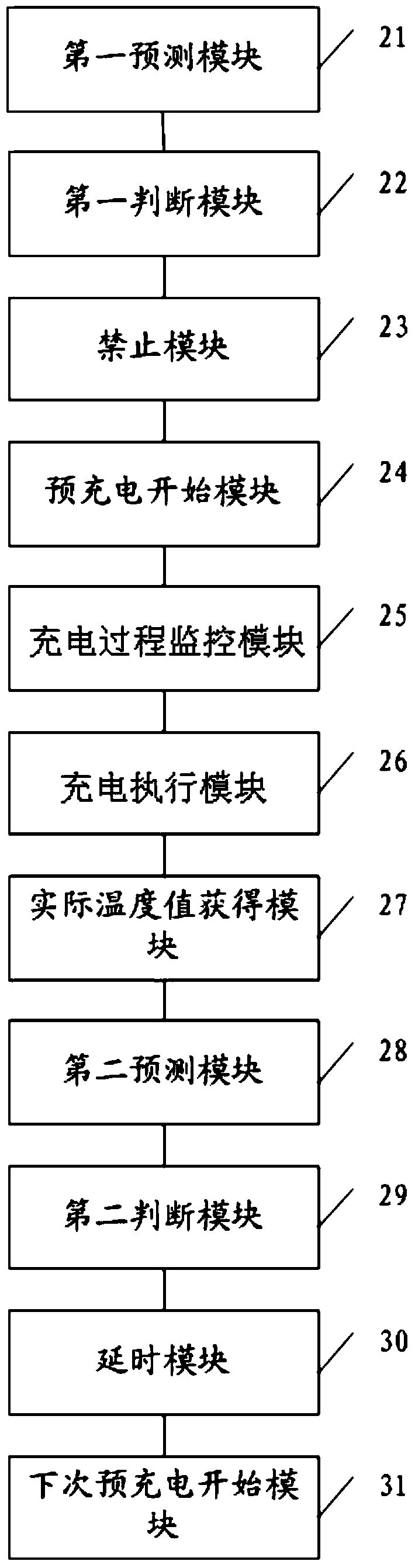

[0108] image 3 A pre-charging control system for an electric vehicle according to Embodiment 2 of the present invention is shown, and the system includes: a first prediction module 21 , a first judging module 22 , a prohibition module 23 and a pre-charging start module 24 .

[0109] Wherein, the first prediction module 21 is used to predict the predicted temperature value of the pre-charging resistor in the pre-charging circuit of the electric vehicle after the pre-charging is completed before the pre-charging starts. Specifically, the first prediction module includes: a difference calculation unit, used to calculate the difference between the voltage of the battery system of the electric vehicle and the voltage of the load circuit; Value obtains the expected temperature increase value of the pre-charging resistance after the pre-charging is completed; the predicted temperature value calculation unit is used to calculate the pre-charging value after the pre-charging is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com