Dual servo motor driven variable degree-of-freedom multi-linkage mechanism for gas cutting blanking machine

A dual-servo motor, degree-of-freedom technology, applied in the field of machinery, can solve the problems such as the variable degree-of-freedom mechanism of the gas cutting blanking machine, the decline of the dynamic performance of the manipulator, and the large cumulative error of the manipulator, so as to achieve a compact structure, improve stability and reliability. High performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

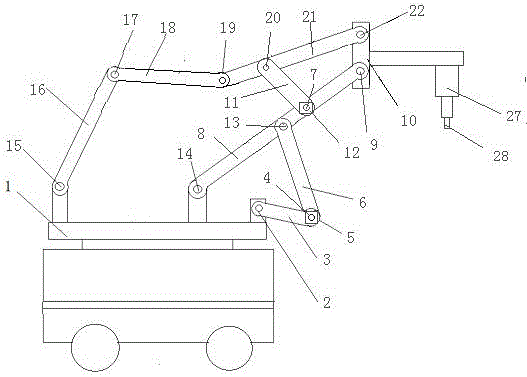

[0007] A dual-servo motor-driven variable-degree-of-freedom multi-link mechanism for a gas cutting cutting machine, including a base 1, a boom lifting mechanism, a gripper link pitching mechanism, a gripper 27, a torch 28, and a servo drive device, the first locking device 5 and the second locking device 12; the base 1 is installed on a movable slewing platform; the boom lifting mechanism includes a boom 8, a fourth connecting rod 3 and a fifth connecting rod 6 , one end of the boom 8 is connected to the base 1 through the sixth rotating pair 14, and the other end is connected to the gripper connecting rod 10 through the ninth rotating pair 9; one end of the fourth connecting rod 3 is connected to the tenth rotating pair 2 The base 1 is connected, the other end is connected to one end of the fifth connecting rod 6 through the eleventh rotating pair 4, and the other end of the fifth connecting rod 6 is connected to the boom 8 through the seventh rotating pair 13; the gripper con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com