Chambering and detaching tool for pin roll

A technology for dismantling tools and pins, applied in manufacturing tools, hand-held tools, etc., can solve the problems of difficult to control the degree of orifice expansion and easy cracking of the orifice, saving labor costs, improving production efficiency, and expanding the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

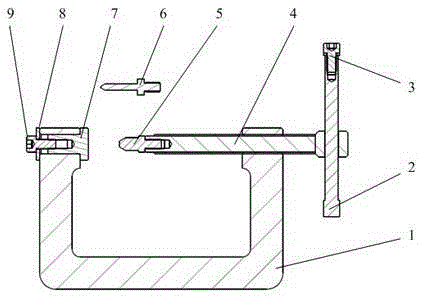

[0016] figure 1 It is a structural diagram of the pin assembly tool involved in the present invention, which includes a base 1, a swing rod 2, a screw A3, a screw rod 4, a reaming pin 5, an ejector pin 6, a spacer 7, a washer 8, and a screw B9.

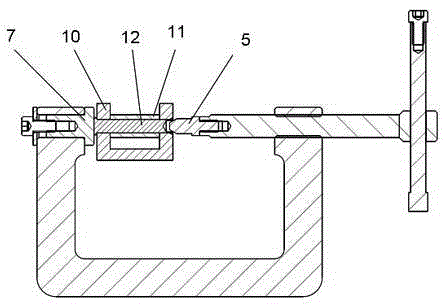

[0017] Such as figure 2 As shown, when the pin shaft is expanded, install the reaming pin 5 to the screw rod 4. The diameter of the reaming pin 5 matches the aperture of the product pin shaft, and the angle of the conical surface of the head is 60°. The screw rod and the base are matched with M12H7 threads. Install spacer 7 at the other end of the base, and fix it with washer 8 and screw B9.

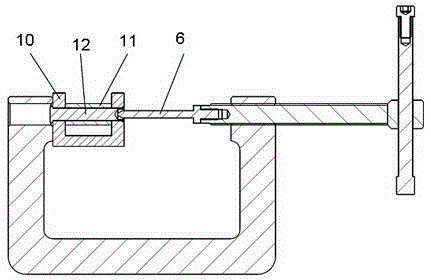

[0018] Such as image 3 As shown, when disassembling the pin shaft, install the ejector pin 6 to the screw 4. The diameter of the ejector pin 6 should be smaller than the diameter of the pin shaft, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com