A polystyrene board trimming device

A polystyrene board and trimming technology, applied in metal processing and other directions, can solve the problems of time-consuming and laborious manual repair, potential safety hazards, and long repair time, and achieve the effect of large repair volume, low maintenance cost, and reduced deviation probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

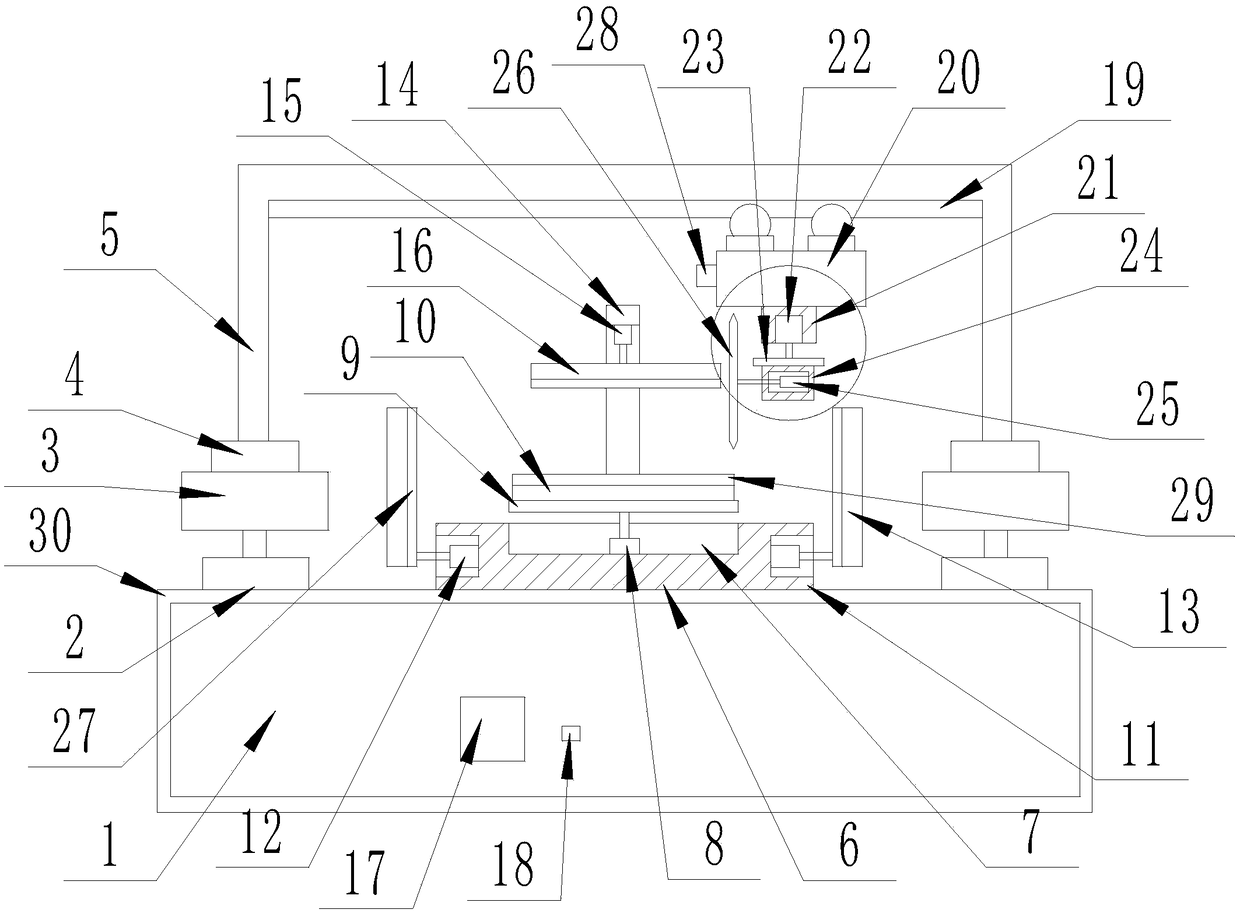

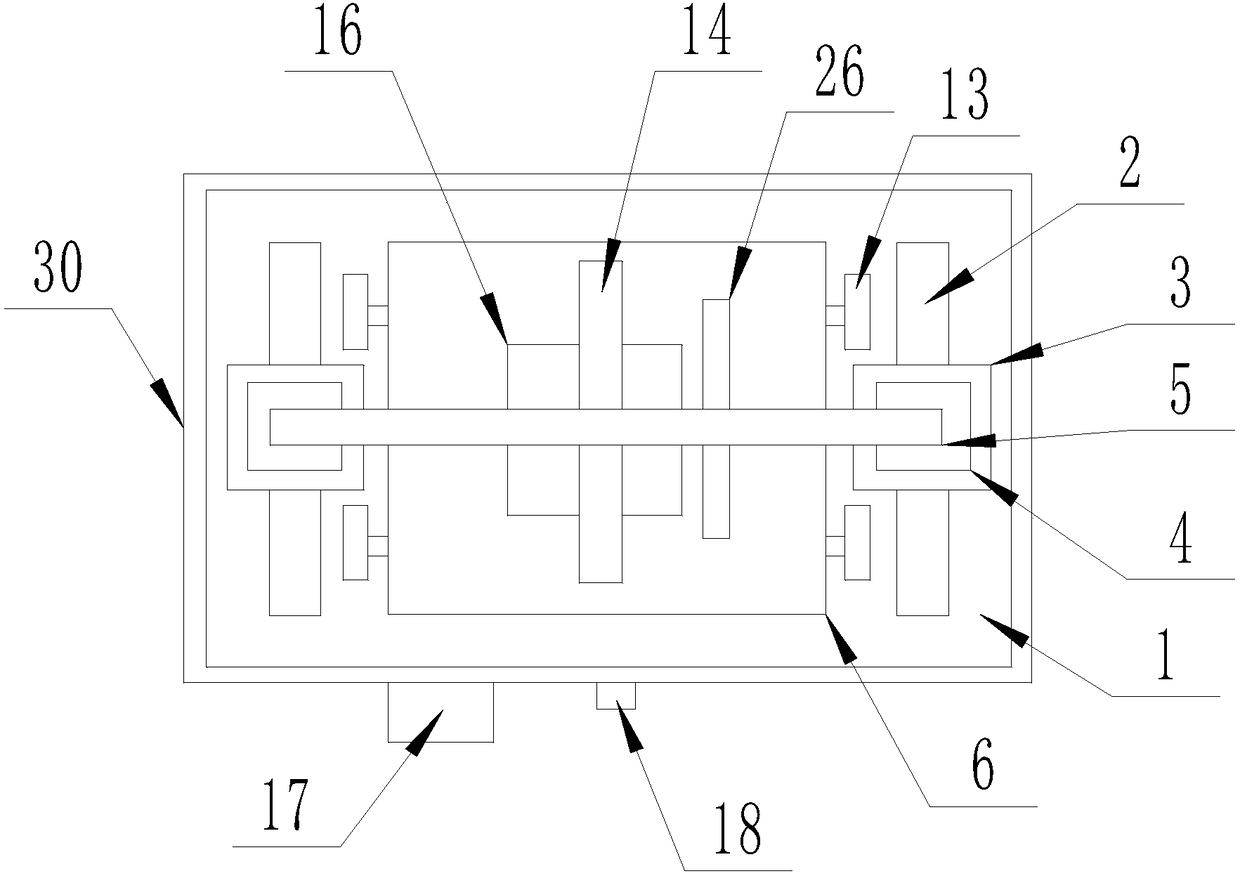

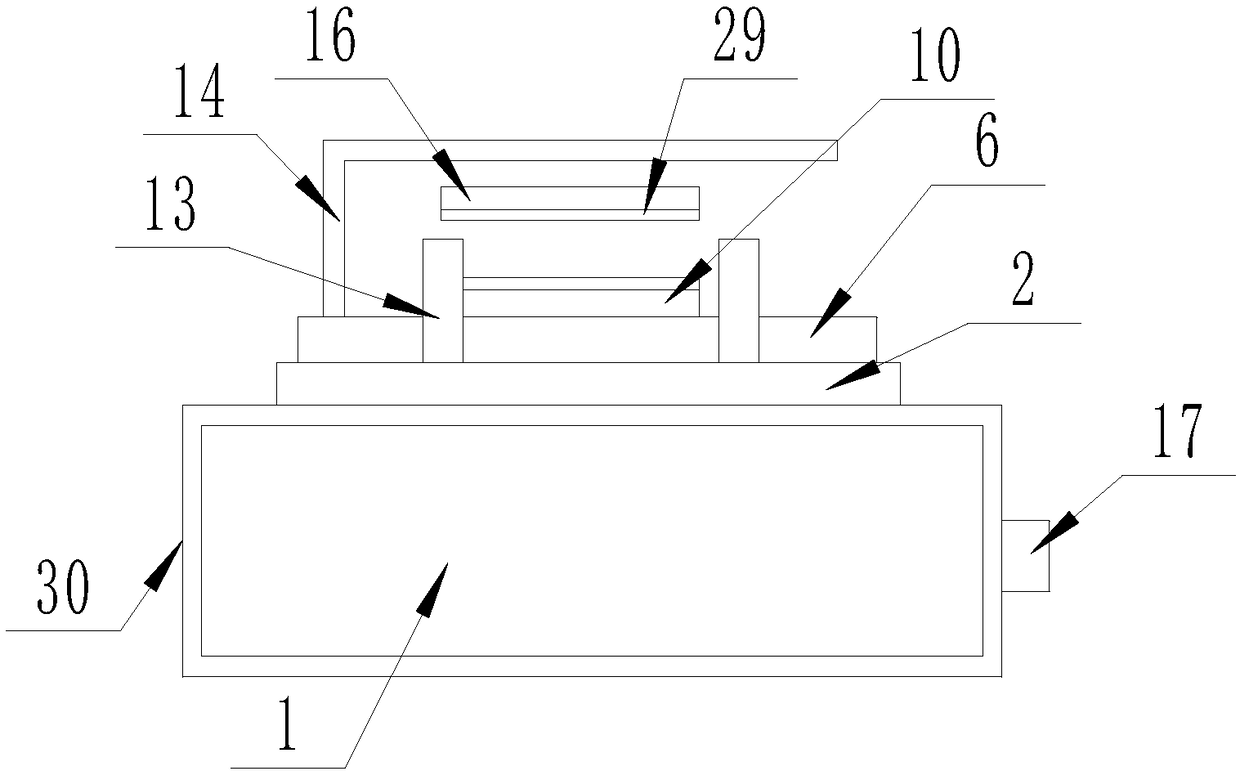

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a polystyrene board trimming device includes a workbench 1, the upper surface of the workbench 1 is provided with a clamping mechanism, and both sides of the clamping mechanism are provided with a No. 1 slideway 2, and each of the one No. 1 electric trolley 3 is provided on the No. 1 slideway 2, and the upper surface of each No. 1 electric trolley 3 is provided with a mounting plate 4, and the upper surface of the mounting plate 4 is jointly connected with a portal frame 5, and the clamping The mechanism consists of a placing platform 6 arranged on the upper surface of the workbench 1, a No. 1 circular groove 7 processed at the center of the upper surface of the placing platform 6, and a No. 1 circular groove 7 set in the No. 1 circular groove 7 with the rotating end upward. Motor 8, the supporting plate 9 that is arranged on No. 1 rotary motor 8 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com