Integrated circuit rotary reversing device and rotary reversing method

A technology of rotation, reversing and integrated circuits, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of integrated circuit damage and low reversing precision, and achieve the effects of not being easily damaged, improving safety, and preventing material jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

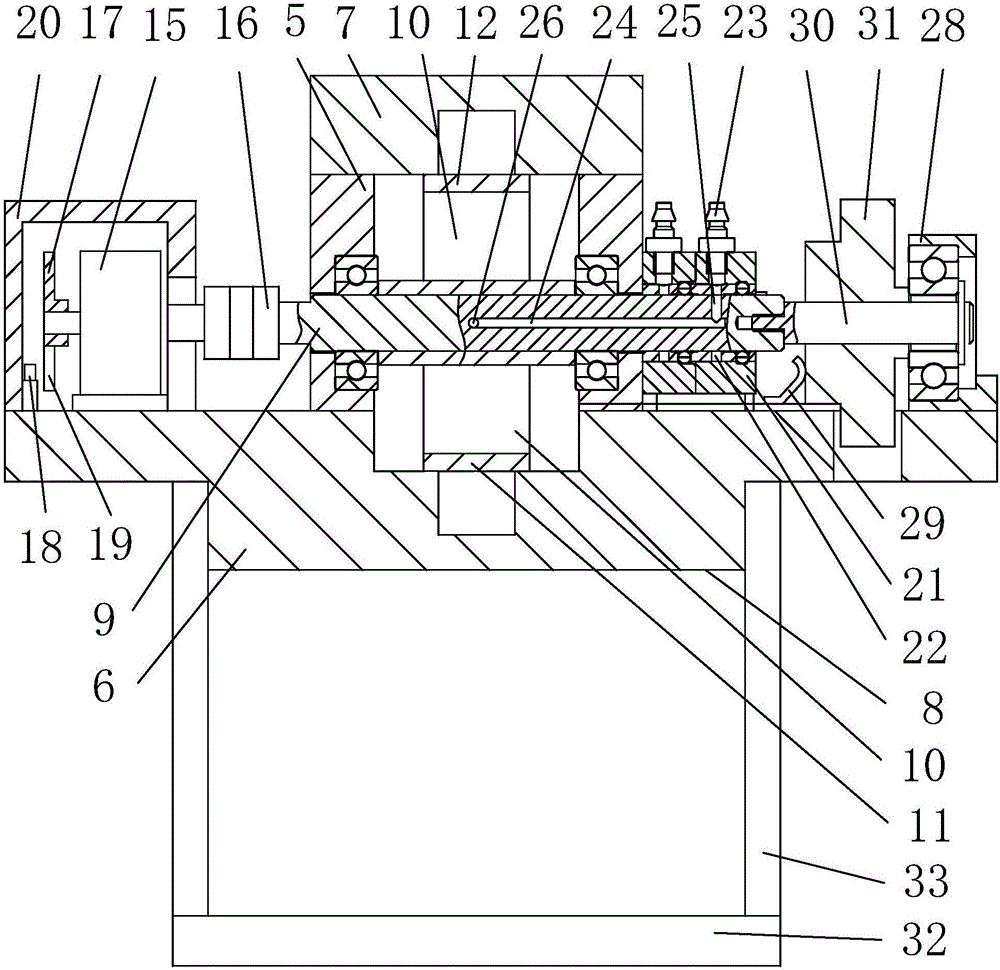

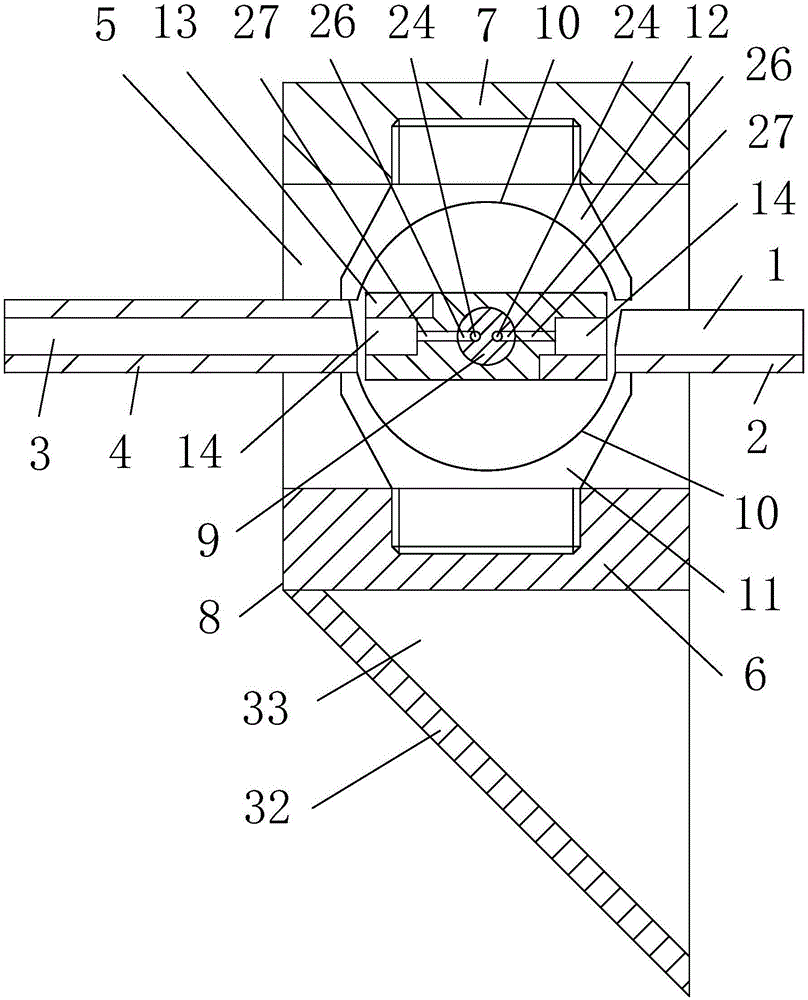

[0017] as attached figure 1 , attached figure 2 Shown: an integrated circuit rotation and reversing device, including: a feed track 2 provided with a feed channel 1, a discharge track 4 provided with a discharge channel 3, a rotary reversing mechanism, and a rotating reversing device provided with an origin detection component Driving mechanism, anti-jamming mechanism, grounding mechanism.

[0018] The rotation reversing mechanism includes: a machine base 8 provided with two end plates 5, a base 6 and a top plate 7, a rotating shaft 9 pivotally connected with the end plates 5 through bearings, and an arc coaxial with the rotating shaft 9 is provided at the upper end Surface 10 and the lower stop block 11 that the lower end is connected with the base 6 screws, the lower end is provided with the arc surface 10 coaxial with the rotating shaft 9 and the upper stop block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com