Film tearing station for thinned silicon wafer processing

A technology for consoles and silicon wafers, applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of uneven force on silicon wafers, affecting device performance, easy to scratch silicon wafers, etc., to achieve uniform force and convenient operation Good sex, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

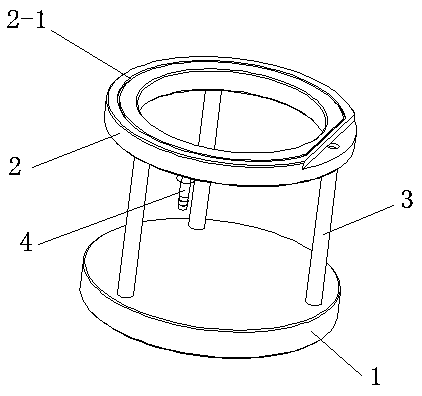

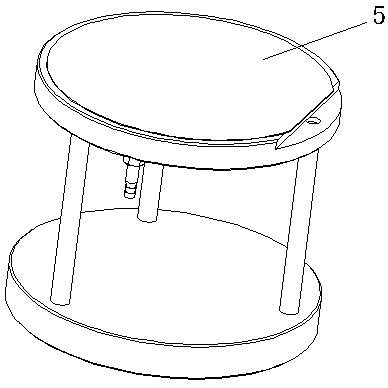

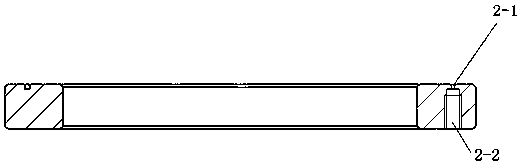

[0011] A film tearing console for thinning silicon wafer processing, the innovation of which is that the tearing film console is composed of a base 1, a support plate 2, a plurality of connecting columns 3 and a connection nozzle 4; the support plate 2 is An annular structure, the upper end surface of the support plate 2 forms an operating surface, the operating surface is provided with an annular groove, the annular groove is located at the periphery of the inner hole of the support plate 2, and a connecting hole is arranged on the lower end surface of the support plate 2, connecting The bottom of the hole communicates with the bottom of the annular groove, and the upper end of the connection nozzle 4 is sleeved in the connection hole; the support plate 2 is arranged directly above the base 1, and the upper end surface of the support plate 2 and the lower end surface of the base 1 Parallel; the upper end of the connecting column 3 is connected with the lower end surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com