Gnaphalium affine rice crust and preparation process thereof

A technology of Maoxiang Guoba and preparation process, which is applied in food science and other directions, and can solve problems such as inability to unload, material adhered to roller groups, and inability to form glutinous rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

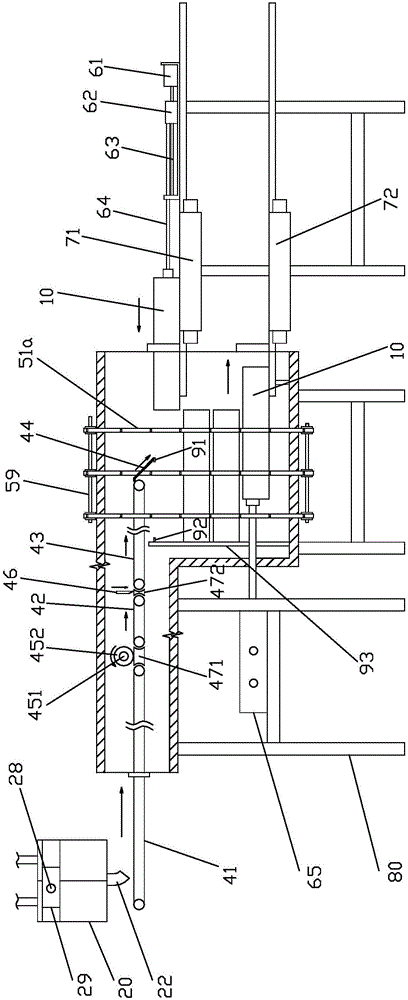

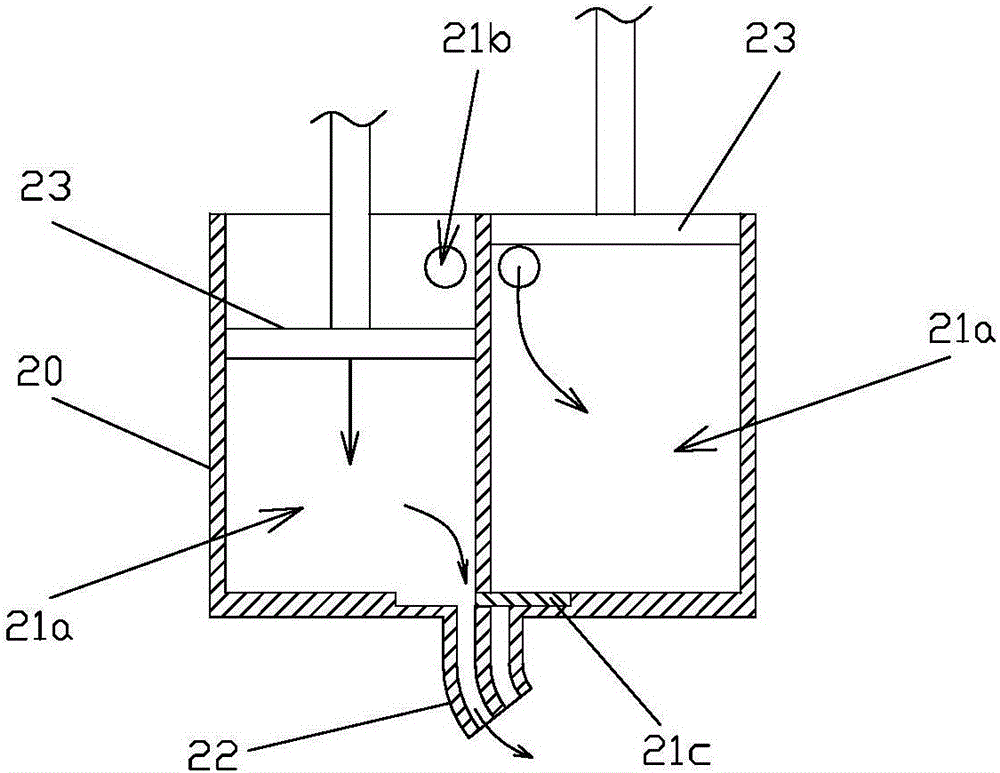

[0023] A preparation process of Maoxiang crispy rice. The tender Maoxiang in early spring is picked, washed and drained, put into a crushing device to make Maoxiang mud, and 5 to 8 parts by weight of Maoxiang mud are steamed in a steamer ;

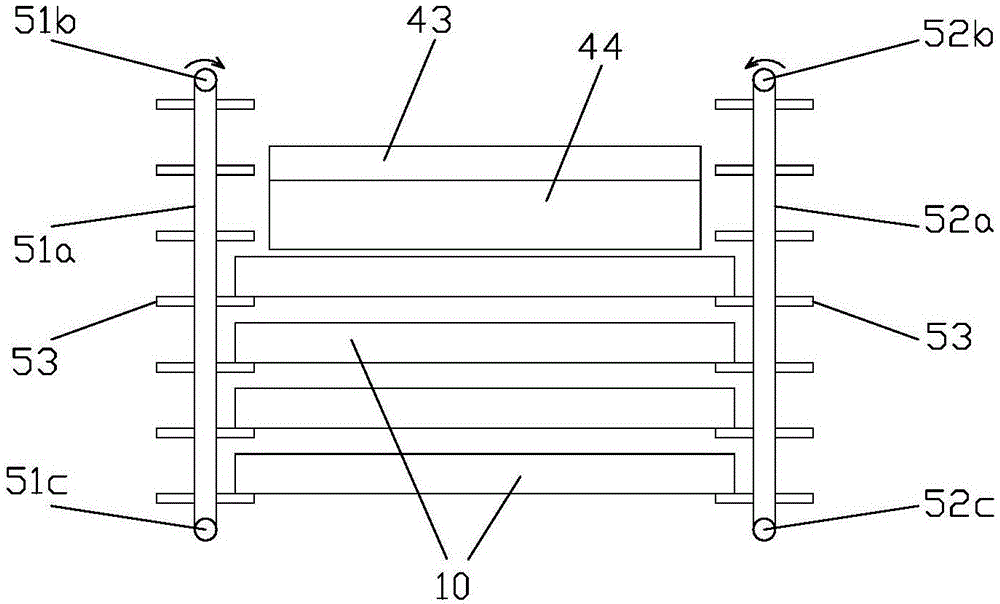

[0024] Wash 100 parts by weight of glutinous rice, add water to the glutinous rice and 2 to 3 parts by weight of diced bacon and cook in a rice cooker, pour the glutinous rice, seasonings and the above-mentioned steamed maoxiang mud into a blender and stir to mix Make a mixed material evenly. After stirring and mixing, the mixed material is transported to the integrated food production equipment for forming and baking by a material delivery pump for forming and baking treatment to obtain rice crackers. Take out the prepared rice crackers and cool them for packaging. .

[0025] Glutinous rice is different from indica rice in that it is extremely viscous after being cooked, so it is necessary to consider the influence of glutinous rice visc...

Embodiment 1

[0045] Example 1: Original Maoxiang crispy rice

[0046] Pick the tender Maoxiang in early spring, wash and drain the water, put it into a fruit juice machine or a mud making machine to make Maoxiang mud, take 5 parts by weight of Maoxiang mud and steam it in a steamer;

[0047] Wash 100 parts by weight of glutinous rice, add water to the glutinous rice and 3 parts by weight of diced bacon for cooking in a rice cooker, pour the glutinous rice, salt and the above-mentioned steamed maoxiang mud into a blender and stir to make Mix the materials and heat while stirring and mixing. After the mixing and mixing, the mixed materials are transported to the integrated food production equipment for forming and baking by the material delivery pump for forming and baking treatment to obtain rice crackers, and the prepared rice crackers are taken out for cooling. Just pack it.

Embodiment 2

[0048] Example 2: Spicy Maoxiang Crispy Rice

[0049] Pick the tender Maoxiang in early spring, wash and drain the water, put it into a fruit juice machine or mud making machine to make Maoxiang mud, take 8 parts by weight of Maoxiang mud and steam it in a steamer;

[0050] Wash 100 parts by weight of glutinous rice, add water to the glutinous rice and 2 parts by weight of diced bacon in the rice pot for cooking, and pour the glutinous rice, salt, chili sauce, lard and the above-mentioned steamed maoxiang mud into the blender Stir and mix internally to make a mixed material, and heat while stirring and mixing. After the mixing and mixing, the mixed material is transported to the integrated food production equipment for forming and baking by a material delivery pump for forming and baking treatment to obtain rice crackers. The crispy rice pieces are taken out and cooled for packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com