Method for forming waterproof coating in negative pressure environment

A molding method and waterproof coating technology, applied to the surface coating liquid device, coating, spraying device, etc., can solve the problems such as easy generation of air bubbles, achieve accelerated escape speed, significant practical value, and reduce coating air bubbles The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

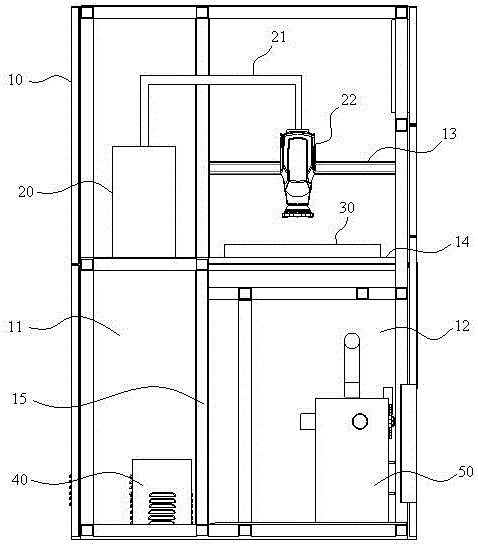

[0011] like figure 1 As shown, the molding method of the present invention is applied to a negative pressure spraying equipment, the negative pressure spraying equipment includes a sealed casing 10, a heat insulation plate 15 is arranged in the sealed casing 10, and the space inside the sealed casing 10 is separated The hot plate 15 is divided into a normal pressure space 11 and a negative pressure space 12. A stage 14 is placed in the negative pressure space 12, a test piece 30 is placed on the stage, and a movable The spraying mechanism 22, the spraying mechanism 22 is provided with a feeding pipe 21, the spraying mechanism 22 is connected with the storage tank 20 through the feeding pipe 21, and a vacuum pump 50 is provided at the bottom of the negative pressure space 12, wherein the feeding pipe 21 adopts a vacuum pump 50. The flexible and deformed hose, the paint is stored in the storage tank 20. In order to ensure that the paint is evenly mixed, the paint in the storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com