A kind of metal strip surface roughness increasing equipment and processing method

A technology of surface roughness and metal strip, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc. , environmental pollution and other problems, to achieve the effect of solving the metal strip surface roughness, controllable surface roughness, and uniform surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

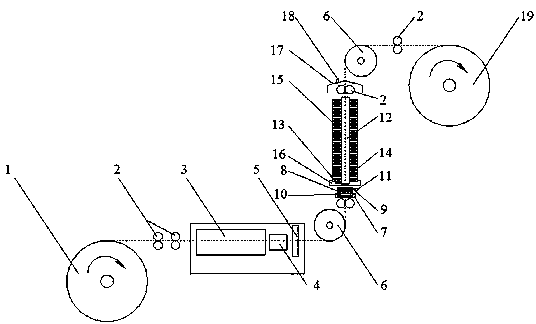

[0031] Utilize above-mentioned equipment, the processing method of the metal strip surface roughness increasing equipment in the present embodiment is as follows:

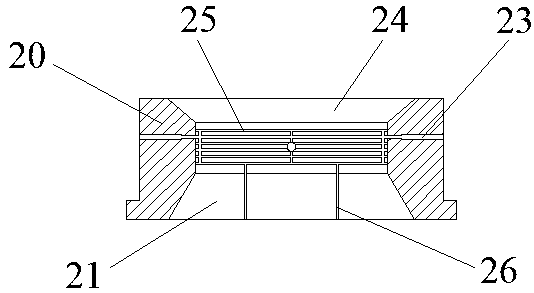

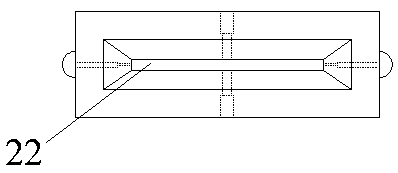

[0032] (a) Install the mold 8 on the nano-metal organic solution recoverer 10, and fix it in the mold base 7, and connect the micropump 11 and the infusion hole 23 through the guide tube 9;

[0033] (b) Turn on the ultrasonic cleaning mechanism 3 and the heating device, and pass the metal strip to be processed with a width of 20mm and a thickness of 0.1mm through the metal strip release mechanism 1, pass through the compression correction wheel 2, and then pass through the ultrasonic cleaning mechanism 3, the physical wiping mechanism 4 and the high pressure The gas air-drying mechanism 5 passes through the mold 8 vertically after passing through the guide wheel 6. The aperture width of the mold 8 is 20.05mm and the height is 0.15mm, and then passes through the ceramic tube 12 in the heating body 14. The temperature...

Embodiment 2

[0037] Utilize above-mentioned equipment, the processing method of the metal strip surface roughness increasing equipment in the present embodiment is as follows:

[0038] (a) Install the mold 8 on the nano-metal organic solution recoverer 10, and fix it in the mold base 7, and connect the micropump 11 and the infusion hole 23 through the guide tube 9;

[0039] (b) Turn on the ultrasonic cleaning mechanism 3 and the heating device, and pass the metal strip to be processed with a width of 20mm and a thickness of 0.5mm through the metal strip release mechanism 1, pass through the compression correction wheel 2, and then pass through the ultrasonic cleaning mechanism 3, the physical wiping mechanism 4 and the high pressure. The gas air-drying mechanism 5 passes through the mold 8 vertically after passing through the guide wheel 6. The aperture of the mold 8 is 20.05mm in width and 0.55mm in height, and then passes through the ceramic tube 12 in the heating body 14. The temperature...

Embodiment 3

[0043] Utilize above-mentioned equipment, the processing method of the metal strip surface roughness increasing equipment in the present embodiment is as follows:

[0044] (a) Install the mold 8 on the nano-metal organic solution recoverer 10, and fix it in the mold base 7, and connect the micropump 11 and the mold infusion hole 23 through the guide tube 9;

[0045] (b) Turn on the ultrasonic cleaning mechanism 3 and the heating device, and pass the metal strip to be processed with a width of 30 mm and a thickness of 0.5 mm through the metal strip release mechanism 1, pass through the compression correction wheel 2, and then pass through the ultrasonic cleaning mechanism 3, the physical wiping mechanism 4 and the high pressure The gas air-drying mechanism 5 passes through the mold 8 vertically after passing the guide wheel 6. The aperture width of the mold 8 is 30.05mm and the height is 0.55mm, and then passes through the ceramic tube 12 in the heating body 14. The temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com